Effortless Lean Efficiency and its Benefits?

As customers, we’ve experienced the benefits of lean efficiency at various points in our life.

According to the Oxford Dictionary, efficiency is achieving maximum productivity with minimal wasted effort or expense, whether in a system or machine or the well-organised and competent work of a person. However, I find this definition somewhat lacking.

Efficiency, in reality, surpasses these descriptions when you encounter efficiency, it sparks a notable “feeling” that you eagerly share with friends and family. Thus, efficiency isn’t an almost experience; it’s a clear distinction between receiving it or not.

Contrasting Experiences: Air Travel

Imagine this scenario in air travel: a punctual flight, seamless check-in, and prompt luggage retrieval. A taxi is readily available at the airport exit to transport you to the hotel. The travel plans and the services you’ve used have demonstrated their effectiveness, delivering tangible value.

Upon arriving at the hotel, you find the reserved room clean and functional, and you’ve paid the agreed-upon price. When these experiences occur, you eagerly share them with friends and family. Highlighting the efficiency of the airport and the hotel. There is a strong possibility, that you received the benefits of lean efficiency.

Now, imagine the airline misplaces your luggage. At the hotel, you endure a two-hour wait to check in due to an unclean room. In this situation, it’s fair to label it as an almost experience. So, the organising company acknowledges the mishap, apologises and offers a free meal voucher. When recounting this incident to friends and family, the conversation revolves around describing this near-miss experience.

Contrasting Experiences: Service Vehicle

You take your vehicle in for repair. At this point a smiling service advisor greets you, providing a repair cost and informing you of the estimated time for the vehicle’s readiness. Overall, this establishes a clear and active communication process. So, the vehicle is ready, you can collect it. You find it repaired to standard and sparkling clean. The invoice is ready and to the value quoted. Then you drive out of the service centre and feel confident that your vehicle repair is to the standard. Upon encountering such a situation, you are compelled to undergo the benefits of lean efficiency.

Your colleague at work mentions that their vehicle needs service, you automatically respond by recommending the service centre you used, explaining how easy they were to do business with.

In contrast, picture a situation where a delayed vehicle repair results in you missing a vital meeting. The company promptly apologises and elucidates that, owing to the delay, a special valet cleaning was executed on the vehicle. Despite this, the situation remains an almost experience, and when sharing with your colleague, that is precisely what you communicate.

Contrasting Experiences: Public Toilets

Now, consider public toilets: if they are open and spotlessly clean, each toilet stall has paper and clean bins. The soap dispenser is full, and the paper roll for drying hands is available. The locks function, the toilet seats are not broke, and it smells fresh. In this case, you’ve received value because the cleaning company responsible adheres to a high standard. Ensuring hygiene in a public area and contributing to your and your family’s health.

Contrastingly, if you enter public toilets and find them dirty, with no paper, soap, or a way to dry your hands after washing, it’s an almost experience. You don’t come out of the area feeling hygienic.

The Core Concept: Value for Payment

The benefit of efficiency lies in fulfilling the value paid for—a concept that resonates with lean principles. Achieving this begins by understanding, defining, and recording the value provided to the customer. The value, comprising of processes, is mapped using a value stream map. Once mapped, the organisation actively engages with the workforce, observing the work and soliciting their input on improvements.

Collaborative Improvements: Engaging the Workforce

Collaborating with the workforce, changes are implemented by eliminating waste and optimising processes for current efficiency. Waste removal, involving less walking, lifting, and confusion, contributes to creating a less stressful environment – a place where everyone knows what to do, where to do it, how to do it, and when to do it. The attained, process is standardised to foster stability. This ensures consistent efficiency every day with every customer. Standardised work not only maintains quality but also facilitates swift and easy training for new staff members. They have received the benefits of lean efficiency.

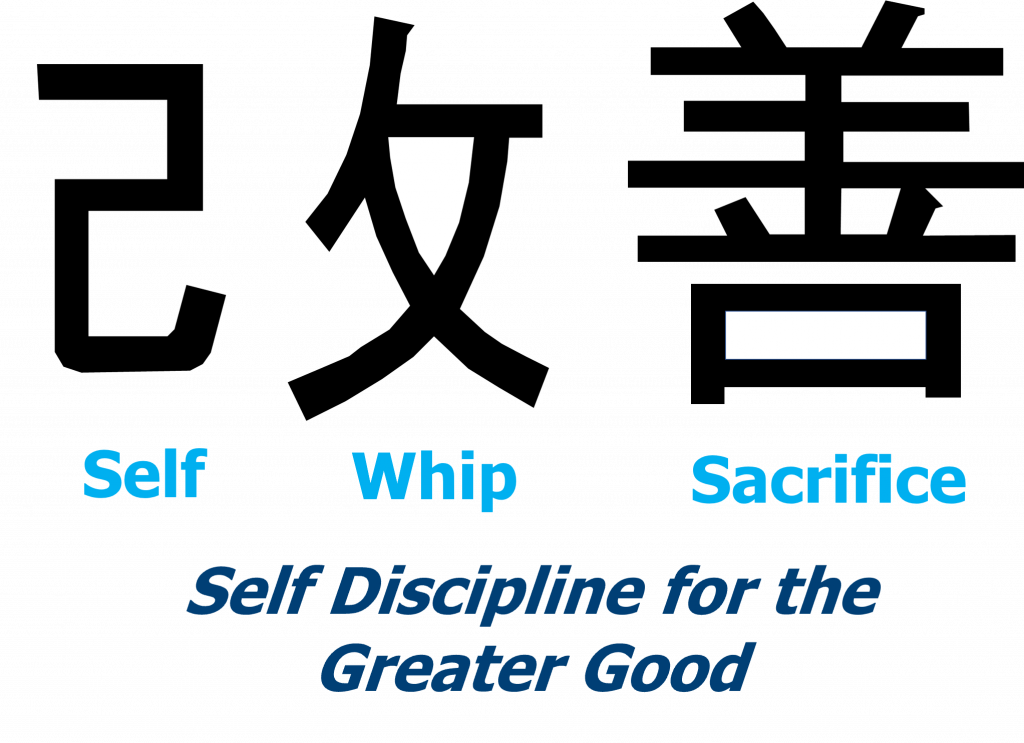

Time is then dedicated to continuously remove barriers to the flow of value, this makes improvement a diligent and ongoing practice through Lean Problem-solving methods known as Kaizen Embracing the kaizen spirit. This continual application of lean tools yields benefits for the organisation, the workforce, and the customer. Let’s explore the efficiency benefits this process brings to all parties.

Value Stream Maps

Value Stream Maps maintain the customer-centric focus additionally reminding both leadership and workers about the customer’s significance. The value stream map pinpoints the specific waste to eliminate. This actively engages the worker’s understanding of processes, their impact on the entire team, and how it impacts the customer. Empowering workers with a voice and problem recognition tools enables them to suggest improvements within the lean framework, fostering trust, teamwork, and innovation.

-

Learning to See£46.00

Learning to See£46.00

Leadership gains a deeper understanding of processes, encouraging collaboration with those executing the work, leading to the discovery of more effective and economical countermeasures to problems. This collaborative relationship builds trust between leadership and workers. Where both parties receive the benefits of lean efficiency.

Standardisation involves implementing current best practices and establishing stability in the workplace. It is also crucial to note that stability doesn’t imply rigidity. Stability ensures that, even after a jolt or shake-up, the process returns to its origin, similar to shock absorbers in a car.

Stability Through Standardisation

When we achieve stability in the workplace, it transforms the space into a haven of calm efficiency. Where the work is predictable and manageable within the given time. Standardisation creates an environment where deviations from the norm are promptly noticed, and efforts are made to address the return to standard. Standardised processes guarantee consistency in quality and supply, as they reduce errors that could impact customer value. The customer receives the benefits of lean efficiency.

Flow in Workspace: Responding to Customer

Once the value stream maps are complete and the organisation achieves stability, they actively work on creating flow in the workspace. Flow enables the pull method in lean organisations, responding to customer demand instead of pushing products or services. This reduces overproduction and unnecessary inventory, ensuring customers can purchase the requested product every time at the agreed price.

Symptoms of bad flow are evident when work intermittently stops and starts. Resulting in waste and bottlenecks. In addition, flow visually represents the work, with bottlenecks offering clues on where to focus Rapid Problem Solving. Flow allows the work to speak for itself.

Visual Management: Amplifying Communication

The work itself serves as the best form of visual management as when it stops flowing, it signals issues in real time. Responding promptly is ideal, as the problem is most visible at that moment. Other visual management forms provide the ability to view the work as history and alter it to the present condition. This space facilitates discussions between leadership and workers about the actual work and how to move it forward to completion. Visualisation brings clarity to communication and serves as a crucial trust and innovation builder in the workplace.

Huddles using visualisation stay focused on the work, avoiding distractions and proving to be the most time-effective response.

Just in Time Minimising Delays and Costs

Implementing Just in Time (JIT) is often expressed by the words “sell one buy one, or sell one make one” which ensures materials or information are available when needed, minimising delays and cutting costs. This actively addresses the waste of excess stock and work in progress. Contrary to common misconceptions, remedying shortages by ordering more stock or assuming that a high volume of work in progress indicates productivity are both incorrect.

Achieving a state of JIT is difficult to achieve without robust quality inventory control systems, these can be either digital or manual. Once all stocking parameters are correct, the supplier relationships become vital to ensure a consistent supply. When these elements align, stock-hold is reduced to a more sustainable level. This aids in storage cost reduction and improves cash flow.

Work in Progress

Reducing work in progress translates to money in the bank. As work in progress can mask detrimental practices within an organisation, covering both true revenue and profit.

While addressing work in progress may cause consternation as some perceive it as a lack of work, the revenue and profits tell a different story.

Both inventory and work in progress represent the areas that challenge leadership the most, exposing underlying problems or gaps between the current state and the desired state. Coaching people to embrace necessary changes requires patience and an understanding that these problems existed all along; recognizing them can be discouraging. A lean coach can provide support and perspective, helping everyone navigate through this hurdle and significantly improving the bottom line and cash flow.

Kaizen, Continually Improving:

Kaizen is the Japanese word for continuous improvement. This involves small incremental improvements that enhance or maintain the value for the customer. Consider a common problem globally: increasing electricity bills. Addressing these changes like switching to energy-saving bulbs, adjusting equipment operation during cheaper hours, and consciously using energy-efficient devices contribute to incremental improvements without significant sacrifice.

Kaizen is a response to a problem; if it doesn’t solve the problem, there has been no improvement. The absence of Kaizen in an organisation can indicate the likelihood that the organisation is deteriorating, as it fails to respond to the small incremental changes that happen every day.

Respecting People

Every individual globally holds the human right to respect, and it’s crucial to recognise that we operate within diverse societies where perspectives on respect vary. The definition of respect for people within your organisation needs explicit clarity for everyone.

-

Lead with Respect£26.00

Lead with Respect£26.00

There is a company in South Africa that proactively conducted a workshop where a board and sticky notes were used to jointly delve into the meanings of respect and disrespect in their work environment. This interactive session categorises actions of respect on one side and disrespect on the other, gradually refining them to a core set of behaviours aligned with the organisation’s values for both external and internal customers. Suppliers are recognised as integral to this chain of respect, and acknowledge their role in the organisation’s success.

Leadership plays a pivotal role in setting a culture of respect by exemplifying the required behavior. Leadership must transition into teachers and mentors. We must recognise to learn these lessons from the top down.

Respect is a two-way street; those being coached and mentored must reciprocate respect for teachers and mentors. Who brings valuable experience and a comprehensive understanding of the entire process, shouldering increased responsibility for positive outcomes.

The Benefits of Fostering Respect Include:

1. Employee Involvement/Engagement and increase loyalty.

2. Cultivation of innovative ideas throughout the organisation.

3. Establishment of stronger communication chains.

4. Development of innovative responses to problems.

5. Cultivation of loyal suppliers.

6. Generation of customers who enthusiastically recommend your service or product to their network.

Prioritising Value for a Sustainable Future

I’ve shared the benefits of lean efficiency and some of the associated challenges with the hope that prioritising value for the customer will contribute to building a sustainable organisation.

In these challenging times, organisations insisting on constant value for the customer are likely to not only survive but also thrive, as the world grows weary of almost experiences.