And What We’ve Done

We’ve been involved in the history and development of lean in the UK for over 40 years. That’s before we conducted the research that coined the term. Here are some key moments in its development in the U.K. alongside the thought leading action learning activities we’ve been involved with:

Dan Jones & Jim Womack co-write “The Future of the Automobile”

The book identifies the performance gap between Western and Japanese auto producers.

Nissan Factory Opens

The U.K. learns more about Japanese management practices as the first Japanese factory opens

“Machine” is launched revealing the performance advantage of lean producers.

Benchmarking the lean system.

Honda’s car factory opens.

Honda had built cars with BL – the first being the Triumph Acclaim. Now they would start vehicle production.

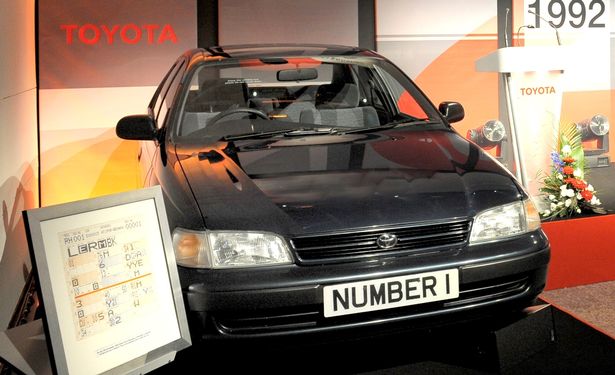

Toyota’s factory opens

Toyota’s first UK built car, the Carina E, drives off the Burnaston production line.

Lean Enterprise Research Centre launched

Dan Jones establishes the World’s first research centre dedicated to Lean Thinking

Supply Chain Development Programme

Dan’s team conduct action research into improving supply chain performance using lean thinking.

International Car Distribution Programme

Dan helps launch icdp. Automotive research downstream of the factory gates..

Womack & Jones write their first HBR articles

The article introduces the term value stream and a new organisational model: the lean enterprise.

The journey to articulate Lean principles begins.

Jim Womacklaunch their landmark best selling book. Still a classic for lean thinkers.

SMMT’s Industry Forum

Industry Forum launched to improve the performance and effectiveness of the UK’s automotive supply chain.

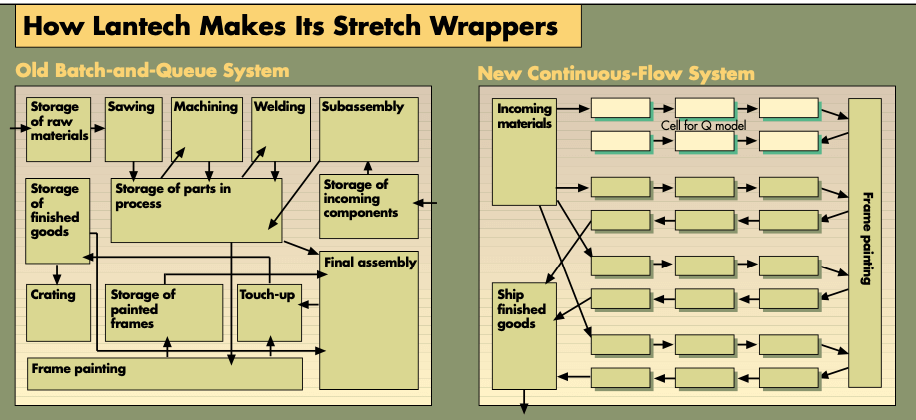

Beyond Toyota: How to Root Out Waste and Pursue Perfection

The 2nd HBR article includes the landmark Lantech case.

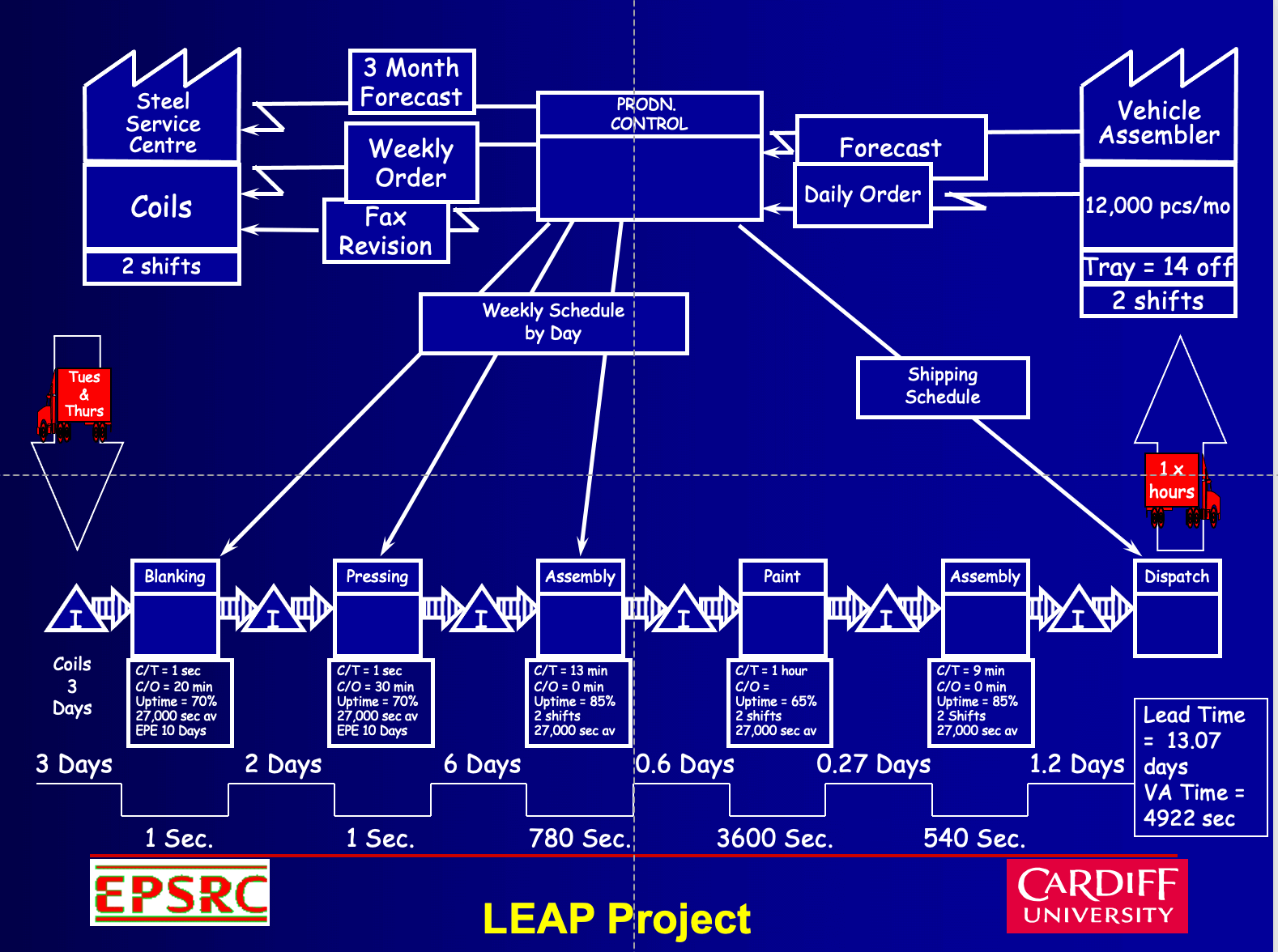

Lean Processing Project (LEAP)

Steel to auto supply chain research. UK & Japanese supply chains benchmarked.

Rethinking Construction

Daniel Jones was a member UK Government Task Force that introduced lean to the construction industry .

Ground-breaking research published.

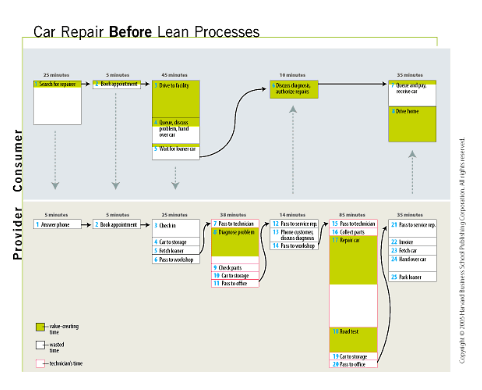

How to improve new car supply & stocking. Uncovering lean car parts distribution & the first research into lean in car dealers.

The First UK Lean Summit

Speakers include Dan Jones & Jim Womack. John Shook launches Learning to See in Europe. Companies include Nissan, Unipart & Tesco.

Movement for Innovation in Construction

Sharing of pilot projects using lean construction.

Lean Processing Programme Research published

David Taylor & David Brunt edit the research.

Efficient Consumer Response (ECR) International Commerce Review launched

NHS Modernisation Agency

Paves the way for lean thinking in the NHS

DTI manufacturing Advisory Service launched

Seeds lean thinking, particularly in SMEs

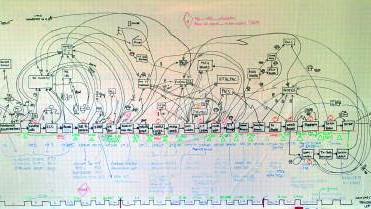

Seeing the Whole published

The first edition of our research into lean supply chain design.

Lean Enterprise Academy Launched

Dan leaves Cardiff University and establishes the not for profit LEA.

First Lean Service Summit, Amsterdam

This was the first Lean Initiative from the Lean Enterprise Academy, together with the Lean Management Institutes in Germany and Holland, to spread lean beyond the shop floor.

The Toyota Way

Jeffrey Liker book published.

Bolton Hospital

Begins it’s lean journey.

Lean Thinking for the NHS

In 2006 the Lean Enterprise Academy was approached by the NHS confederation. We were asked to look at how Toyota’s approach to production could be applied to healthcare. This led to the Lean Thinking in the NHS report.

Lean Healthcare Forums for the NHS

We organised 3 events throughout the year where healthcare professionals came together to learn and share about lean.

1st Global Lean Healthcare Summit

This Summit was a landmark event for the lean healthcare movement around the world. The event sold out with 320 people (over half from hospitals) attending from 147 organizations from the UK, Ireland, Denmark, Norway, Sweden, Netherlands, Belgium, Germany, Italy, Spain, Turkey, Poland, Switzerland, France, USA, Canada, Brazil, India, South Africa, Singapore, Australia and New Zealand.

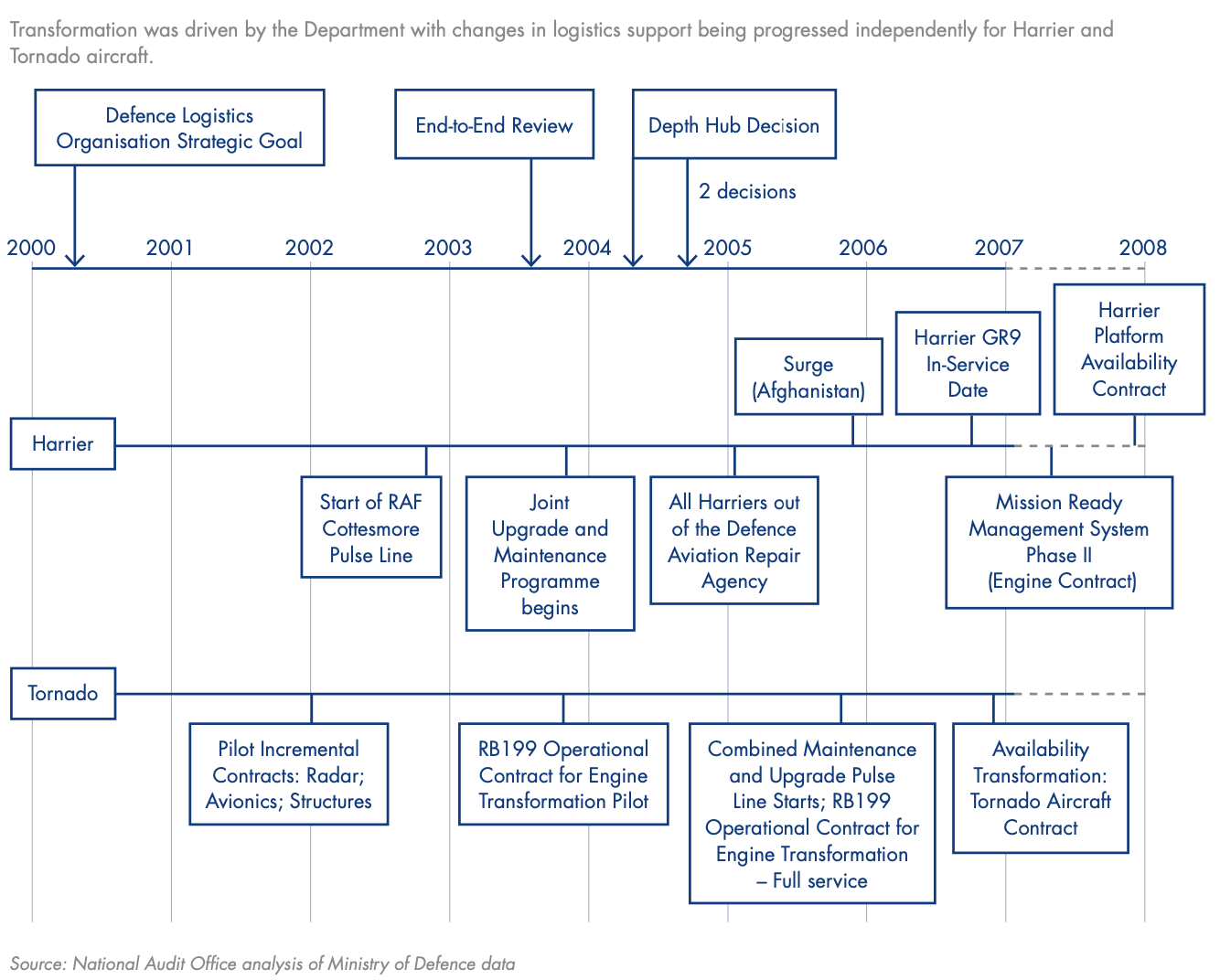

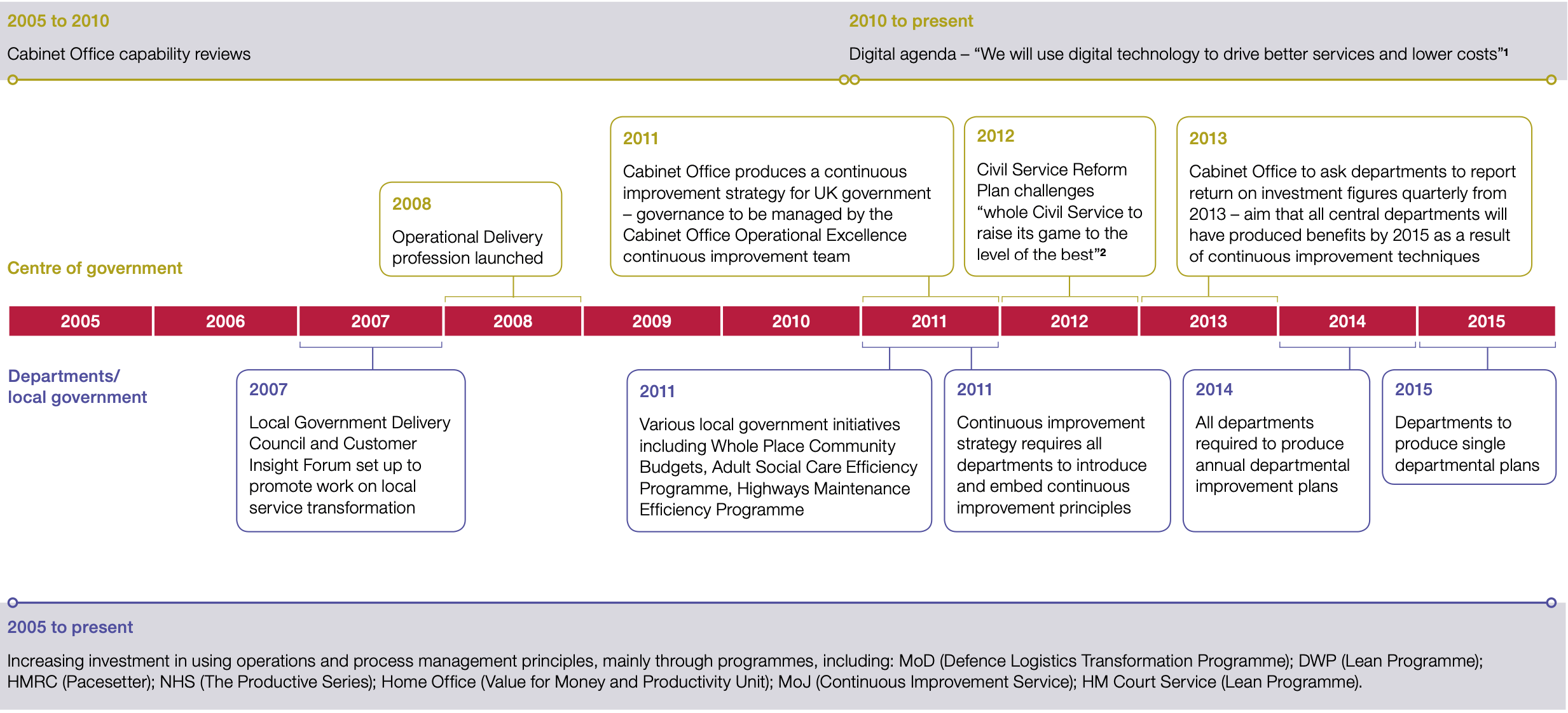

National Audit Office reviews lean across government

Dan Jones and the LEA team provide assistance to government to understand the effectiveness of attempts to introduce lean across government.

LEA launches its Lean Healthcare network

Working in a number of NHS trusts this research club was formed to create experiments in end-to-end patient care.

Managing to Learn Launched

Toyota’s A3 process is explained in the book. Dan Jones and Dave Brunt are amongst the network that help John Shook write the story.

Seeing the Whole 2nd Edition

We updated our supply chain book with a host of cases that we had helped.

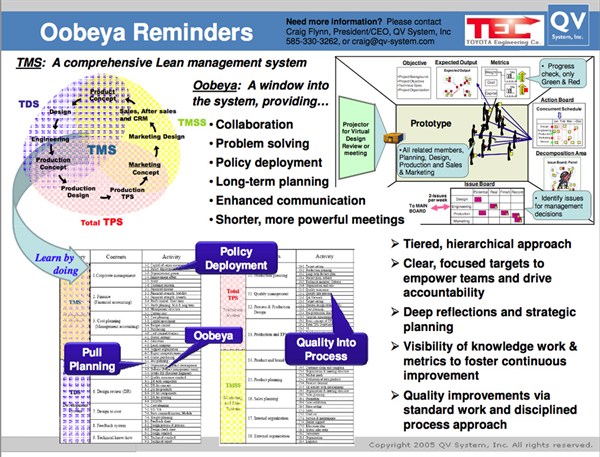

LEA helps explain the use of oobeya

Takashi Tanaka and Sharon Tanner help us explain the use of oobeya for product development and in executive offices..

Solving Business Problems

Our annual event asked what the most important next steps for the lean movement to address were.

Lean Summit – Learning, Educating, Sharing

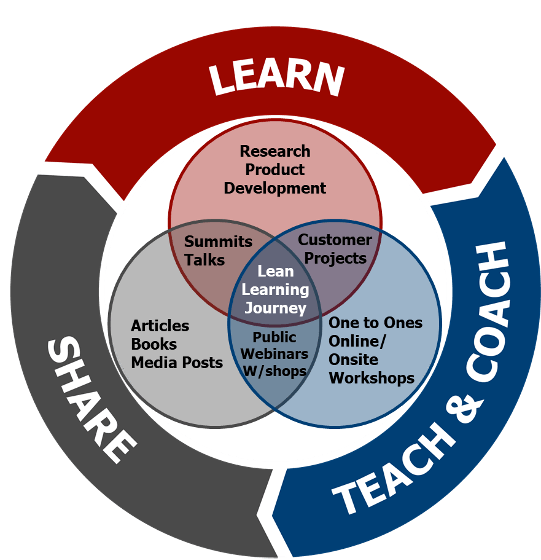

We launched our three core processes and a new website (the previous one to this.) Mike Rother keynoted this event explaining his Toyota Kata book.

Lean Leadership Research Launched

Dave Brunt, John Shook, Jim Luckman, Joe Murli and members of LGN conduct research in the topic. Dave summarises the findings.

We develop our Lean Sharing Days

The first takes place at Cardiff Metropolitan University with our old friend Nick Rich.

Frontiers and Fundamentals

At our Lean Summit, we welcome Art Byrne to the UK. Executive at Wiremold and Danaher and author of The Lean Turnaround, he shares his story. The event also starts our relationship with Toyota Lean Management Centre, based at Deeside.

Lean Transformation

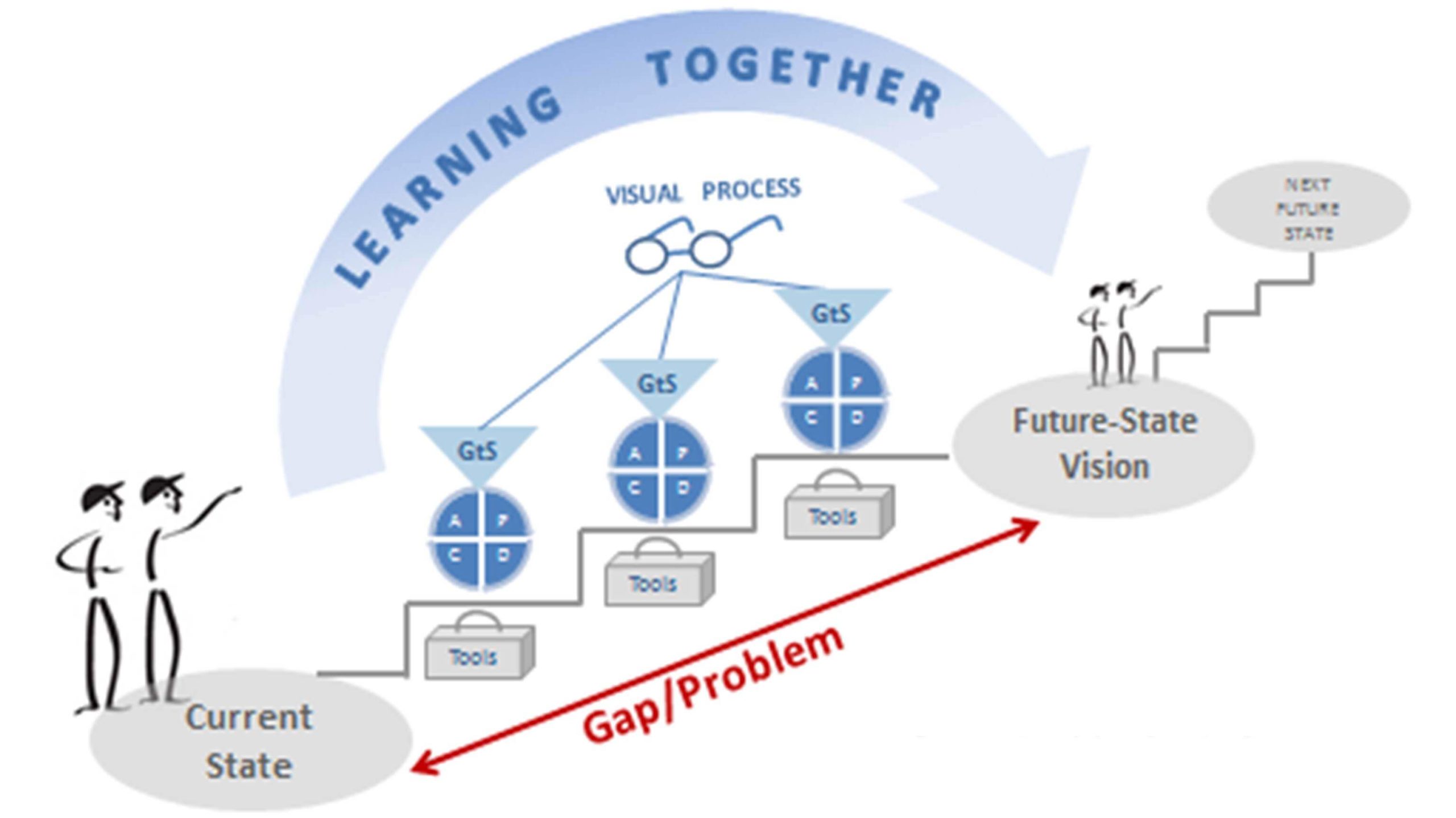

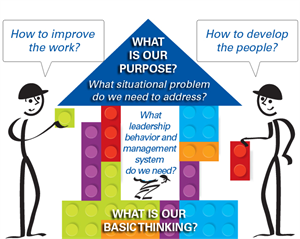

We work on pilot projects to test what John Shook initially calls “The Lean Transformation Model.” The test cases are very successful. We realise that this isn’t a model, but a framework to think about lean implementation.

Practical Next Steps

At our 2014 UK Lean Summit we address the following issues:

What does it take to move beyond legacy assets and mind-sets to involve users in creating new lean solutions?

How to build a management system to spread lean across the organisation?

How to develop leaders to implement, sustain and expand lean transformation?

How to develop problem solving capability in the organisation?

What are the key elements of Lean transformation?

What is the role of a lean team in a successful transformation?

Developing capability to improve the work

We start our research on how the best lean organisations develop capability. The results are shocking. We conclude that certification and competency rarely offer any lasting value and are the antithesis of what the best are doing.

Lean Start Ups & the Old School Lean Movement

At our lean summit we summarise what each of these communities can learn from each other. Observations from Spotify provide some of the picture.

Lean Product & Process Development (LPPDE)

We co-develop an event to share lean in product and process development research.

Lean learning, learning lean

We publish our initial research on how the best organisations learn lean and what the lean community can learn from the findings.

The Lean Strategy

Dan Jones co-authors The Lean Strategy.

The Lean Strategy & The Work of Management

Our annual event explores these themes.

Back to the Roots of Lean

Our Gemba Walk at Toyota’s Deeside Engine facility raises £10,000 for their charity. Toyota shares with participants what it takes to be one of the best lean exemplars in the UK.

What can the world’s of Lean and Education learn from each other?

We co-develop an event to introduce the world’s of education and lean to each other.

New LEA Website Launched

We launch our “Lean Learning Journey” platform as we move lean learning materials and services online.

First Learning Materials Launched

We launch 8 step practical problem solving as the first materials around the Lean Transformation Framework and the 4 level – 1. Knowledge; 2. Understanding; 3. Capable; 4. Train and Coach Others learning framework .

More to follow. Pop back soon as we will be adding more content.