What is Standardised Work?

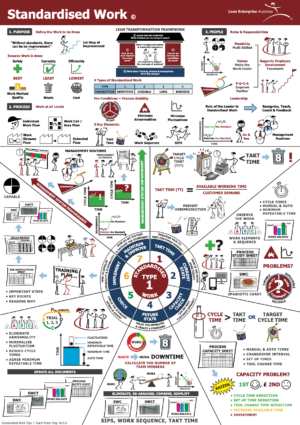

Standardised work is a Lean manufacturing principle that involves creating a consistent and repeatable process to ensure work is done safely, correctly, and efficiently. It helps minimise waste, improve efficiency, and promote continuous improvement. Learn about the benefits of standardised work, including better safety, reduced variability, increased productivity, and improved quality. Discover how to implement standardised work by creating standardised work documents and procedures, training & developing team members, and continuous monitoring and improvement. Improve any process and increase your productivity with standardised work. Without a standard there can be no improvement.

Standardised Work – Skill Level 1: Knowledge

This is a self-paced 1 hour course that is hosted on our online Learning Platform . By completeting this course you will gain the basic Purpose, Process and People knowledge about Lean Standardised Work

Standardised Work – Skill Level 2: Understanding

This is an on-the-job coached course where a Senior Lean Coach will help you gain a better understanding of Standardised Work. Available online or face-to-face.

Want to access all our online courses and webinars all in one place? Starting at just £99.99+VAT/year, our Learning Platform Subscription provides all current and future materials developed by the Lean Enterprise Academy. Click on the subscription logo to find out more information.

Supporting Materials

-

Standardised Work Template£24.99

Standardised Work Template£24.99 -

Standardised Work Facilitation Guide£19.99

Standardised Work Facilitation Guide£19.99 -

Standardised Work Teach Poster£49.99

Standardised Work Teach Poster£49.99

Books

-

Creating Continuous Flow£48.00

Creating Continuous Flow£48.00 -

Kaizen Express£26.00

Kaizen Express£26.00 -

The Toyota Way (2nd Edition)£25.99

The Toyota Way (2nd Edition)£25.99

Webinar

Standardised Work: On-Demand Webinar

This is a video recording of our Standardised Work webinar. Included is access to a video of the webinar, a copy of the presentation slides, a transcript of the webinar, our Standardised Work Teach Poster and the Standardised Work exercise sheets used during the webinar.