Learn how to grow your businesses using Lean Thinking

In 2013, the Lean Enterprise Academy UK introduced me to lean thinking, after the Halfway Group in South Africa acquired the Toyota dealership I managed in Botswana. Lean thinking transformed my management skills into leadership skills. Over recent years I have been helping people to grow small businesses using lean thinking.

My own journey in senior management provided me with experience across diverse organisations in Botswana including an exclusive Safari outfitter operating lodges and camps in the Okavango Delta, a logistics company managing a fleet of reefer trucks between Maun in Botswana and Johannesburg, and a Toyota dealership servicing a vast rural area in the north of Botswana.

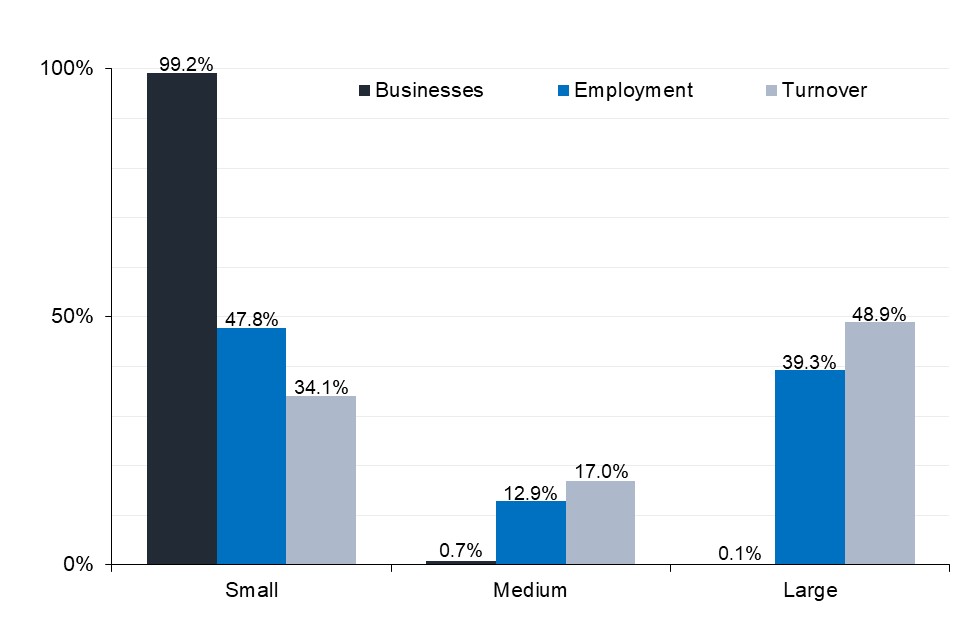

While examining UK business statistics from Gov. uk in 2022, it was interesting to note that 99.2% of the total business population consisted of 5.47 million small businesses (0-49 employees).

I considered the challenges of transitioning from a small to a medium-sized organisation. I pondered the constraints to growth and how lean thinking could empower organisations to make that leap.

Analysing common reasons for growth failure, I contrasted them with my growth journey using lean thinking, employing the dealership I worked at as a model to illustrate the distinctions.

1. Financial Constraints:

Before Lean

The dealership was always fiscally conservative and considered to be very successful. So much so, that we won a President’s Award from Toyota South Africa for financial management. The owners sold the business for no other reason than they were aging and wanted to spend time enjoying their retirement.

After Lean

After two years of applying the Lean Transformation framework, the financial results were impressive.

For every 100 Pula (Botswana currency) of turnover in 2013, we increased with no additional resources to 157 Pula of turnover in 2015.

Every 100 Pula of profit in 2013, increased with no additional resources to 211 Pula of profit in 2015.

For every 100 Pula of available free cash in 2013 increased with no additional to 261 Pula in 2015.

This is an apples-to-apples comparison, maintaining the same team, quantity of staff, demographics, and customer base.

2. Operational Inefficiency:

Before Lean:

The dealership used individual incentives to drive productive behaviour in the service centre, this resulted in skilled experienced technicians manipulating the vehicles they chose to work on. This created inefficiencies, delays, and reputation issues. Due to less experienced technicians handling the more difficult tasks on a vehicle. The experienced technicians clocked up incentive hours on easy jobs, focusing only on their own pockets and not on the customer. We worked hard at controlling this but were not entirely successful.

After Lean:

Our understanding of operational efficiency improved, allowing us to remove waste and increase the flow of work. We stopped the individual incentives and gave a group incentive, encouraging the skilled experienced technicians to assist with difficult work. In 2015, our service centre progressed from servicing an average of 17 to over 40 vehicles per day, positively impacting parts sales and customer satisfaction.

3. Market Competition:

Before Lean:

Botswana’s small market and government dependency posed challenges. Botswana has a small population of only 2.4 million with most of them living in the southeast of the country. We were situated in the North West. Eighty percent of our revenue came from the Government and Parastatals making it a very competitive environment.

After Lean:

Our customer base did not change but our improved customer service, fix-it-right first-time policy, and our ability to stick to repair budgets and time helped us to become a preferred supplier, enhancing our competitiveness financially and logistically.

4. Lack of Innovation:

Before Lean:

Leadership was just too busy and pressurized to spend the time being creative or innovative. Problems were frowned upon as being bad.

After Lean:

Identifying and solving problems together became part of who we were as an organization. Improving the way we worked became a team effort, and we all became more creative. The more we improved the work the easier the work became to do. Innovation became our strength.

5. Talent Shortages:

Before Lean:

Lack of access to skilled employees affected work quality and timelines. Although we were coping with our workloads we were reluctant to grow due to a lack of skills in the area.

After Lean:

Focusing on developing our people and increasing productivity allowed us the time to train technicians and support staff. Having the talent available allowed us to expand the business to build a new dealership in another town at the end of the two years.

6. Technological Obsolescence:

Before Lean:

As a Toyota dealership, we did not have the problem of obsolescence, but this did not mean that technology did not provide us with challenges.

Our greatest technology challenge was new model vehicles with complex computerized electronics. Our dusty, high ambient temperatures with transient flood water challenged this technology daily impacting the profitability of the service centre.

After Lean:

Emphasising Master technician training and Lean Problem-Solving skills address our technological challenges, improving vehicle repair efficiency.

Ensuring that we fixed a vehicle right the first time, went a long way toward our fiscal success, a comeback vehicle never makes money. Neither does a vehicle that takes longer to repair than the allocated flat rate.

7. Macro-Economic Factors:

Before Lean:

Conservative fiscal practices were always in place, in difficult times the response was to always cut costs, which at times resulted in redundancies.

After Lean:

We learned to remove waste within the organisation, this never during my time at the dealership involved redundancies. We looked at the processes and we innovatively responded to the problems to solve using A3 thinking and our understanding of our environment.

8. Regulatory Challenges:

Before Lean:

Meeting specified standards was a requirement from the shareholders, Toyota, and the Botswana Government. We worked hard at ticking the boxes and with a great deal of effort managed to maintain all regulatory challenges.

After Lean:

Understanding the “whys” increased our purposeful work and the implementation of 5S in its true sense kept every day to standard. Regulatory challenges became an opportunity to improve.

Conclusion:

In my working life, transitioning from classical management to lean thinking transformed the way I thought about the work to be done. It was only luck that brought this amazing gift of learning into my life.

The Lean Enterprise offer affordable learning processes, materials and other resources online, focusing on teaching leaders and enabling them to carry the learning to their teams in the most cost-effective way possible. Learn more here.

In 2024 take the lean leap into growth and grow your businesses using Lean Thinking.