At the end of February I attended the Media Day at the 91st Geneva International Motor Show. I particularly wanted to explore mobility and innovation. Are there insights for lean product development lessons to be learned? Historically it has always been the show where car manufacturers launched important new models to the European market. Being held for the first time since 2019 (the Covid pandemic halted the show in 2020) a slimmed down show still had 37 exhibitors with 13 world premieres and 10 European premieres. Interestingly, the OE representation was dominated by Chinese manufacturers and by the launch of electric vehicles.

Car Manufacturers and Mobility

I was particularly interested to hear how many manufacturers would talk about mobility. MG did, even weaving AI and mobility together. But the reality is that most car manufacturers are focussed on selling cars (and parts that keep them on the road.) That is, after all, how they (currently) make their money. There were a couple of niche vehicles with an interesting take on the mobility conundrum. The Microlino is a modern interpretation of the Isetta Bubble car. It includes space for an electric scooter in the back. Silence displayed the SO4 Nanocar, an electric car with removeable and exchangeable batteries which are available through subscription.

Automotive Design and Development

Automotive design and development is a fascinating area. Companies beyond automotive can learn from how the industry develops new products. Particularly how the best companies use lean product and process development methods. This year there was a design area. Pininfarina, the Italian design house responsible for icons such as the 1955 Alfa Romeo Giulietta Spider, the Ferrari 250GT and Daytona and humble everyday cars such as the Austin A40 and the Peugeot 205 showcased their hydrogen-powered Enigma GT. The concept car features an AR windscreen that employs AI to assist drivers in real time. The windscreen flashes points of interest and integrates driver assistance systems. It also has an autonomous driving mode. In contrast to Pininfarina’s glimpse at the future, Totem Automobili displayed the GT Super. It is a modern interpretation of the classic Alfa Romeo Giulia. It is truly beautiful, with exquisite attention to detail.

My reflections? The auto industry continues to innovate. There are new players in town too – the Chinese brands. Their presence at Geneva is a signal of intent regarding the European market. Their technology of choice – electric vehicles.

What about Toyota?

So, as a lean thinker, does this mean Toyota has lost its way? Knowing Toyota’s track record, probably not. Government legislation has inevitably driven the launch of more electric vehicles. But, I can’t help thinking the political decision making process and the subsequent strategies at a number of auto makers has been very similar to the process that led to the increase in diesel passenger car sales in the early 2000’s. It’s a focus on one set of metrics (that aren’t holistic) and one technology rather than a range of technologies that meet situational needs.

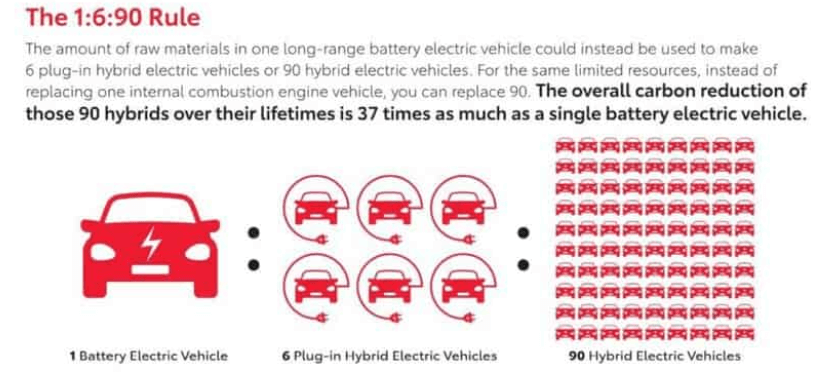

If the answer to the question “what problem we are trying to solve” is the overall carbon reduction, then Toyota’s “leaked document” which reveals the automaker told its dealer network that the lithium and other rare materials required to build one EV, could be used to build 6 plug-in hybrids or 90 conventional hybrid vehicles provides a different perspective. This 1:6:90 rule means that “the overall carbon reduction of those 90 hybrids over their lifetime is 37 times as much as a single battery EV.” It also means that stumbling blocks such as range anxiety, charging infrastructure and vehicle cost can be managed.

Lean Product Development – Set Based Concurrent Engineering

Of course, lean thinkers know there is some underlying thinking at play here too. That of “set-based innovation” also called “set based concurrent engineering (SBCE). In SBCE the design team:

- Simultaneously explores multiple solutions for every subsystem of both product and manufacturing system.

- Aggressively attacks those solutions with rapid, low-cost analysis and tests, progressively eliminating weak solutions.

- Uses the results of analysis and tests to create a trade-off curve knowledge base that defines the limit of the possible.

- Converges on a solution only after it has been proven.

Whilst it’s acknowledged that looking at multiple alternatives isn’t free, it’s more economical than you might think when it’s done in a lean way. Importantly, we shouldn’t converge while there is no proven solution or possibly better alternatives to the proven solution. You can learn more about the principles of lean product and process development in the book below:

Lean Product and Process Development 2nd Edition

Including five new LPPD case studies

Themes at our UK Lean Summit 2024

At our UK Lean Summit later this month we are addressing the environmental challenge specifically in two keynotes and a learning session. Firstly, Jon Hunt, Senior Manager, Hydrogen Transformation Manager, Toyota GB will share the story of the commercialisation of the Toyota hydrogen fuel cell electric vehicle (FCEV) programme in the UK. It’s a great example of SBCE thinking.

Secondly, we have invited Professor Josh Hsiu Hung from National Cheng Kung University, Taiwan to share thoughts on lean product and process development capability. The actual process of developing lean thinking and practice in the design and development of new products.

Back to the motor show, I realised how much I enjoyed them. My late Dad, a motor engineer, took me to my first one when I was still at school. Later in life, I took him. We’d look at paint finish, panel gaps, material uses, new features, ergonomics and how easy the cars were to work on. This year had a different feel. I went with my eldest daughter (a product design engineer) who starts work for an OE auto maker on completing a Masters later this year.

While the car plays a key role in many of our lives, shows do something that no online car launch can do – we get to look and go see for ourselves each vehicle on display. They provide a platform for the industry to engage with the public and end customers and an opportunity to network with their peers and other members of the industry. The 91stGeneva International Motor Show wasn’t as big as the pre-pandemic events, but it was thought provoking. I hope to see more participation from manufacturers next year and, you never know, some might really present on mobility.