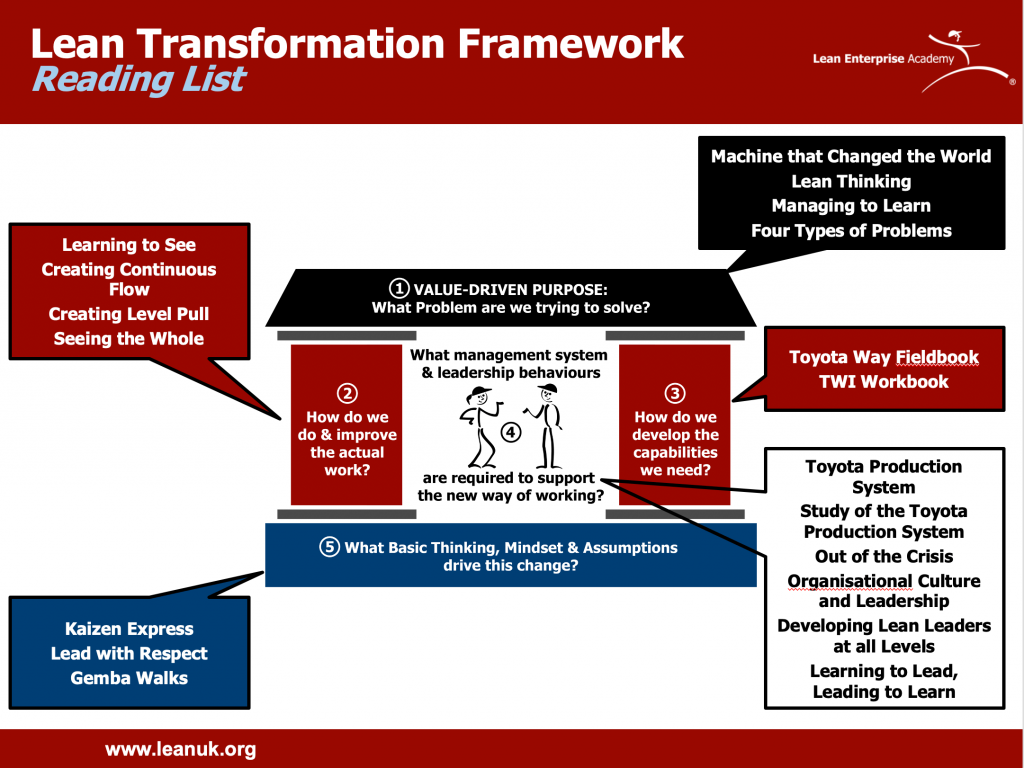

What are the best lean books to read? We stock over 70 titles in our store and they all have one thing in common. That is, that we found them useful and thought they added value for an organisation or individual wanting to gain knowledge about lean. Answering the question of which books someone should read is difficult to answer. As lean thinkers know, the definition of “the best lean books” depends upon the situation of the reader and on the “problem” they are trying to solve.

As we get close to the launch of our Lean Transformation Framework webinar, I have reviewed an article I wrote in 2014 titled “Desert Island Lean.” The premise behind the article was that, in the style of “Desert Island Discs”, the radio programme broadcast on BBC Radio 4, I select the Lean books I’d take to be cast away on a desert island. The rationale for the choices is that each of these books is particularly useful for part(s) of the Lean Transformation Framework.

The Classic Lean Books

An obvious starting point is reading the classic texts. Not everyone that is now applying Lean Thinking is in the auto industry, but understanding where Lean comes from is so clearly explained in the Machine that Changed the World. The book is a classic and where the term Lean was first used. The book shows that lean isn’t just about (lean) production. In addition it explains application in new product development, production operations, the supply chain and dealing with customers.

I’d then go on to read about the generic principles described in Lean Thinking and Lean Solutions. Both help explore issues from a lean perspective. This provides a foundation for asking “what problem are you trying to solve?” This simple question is frequently the starting point for learning about lean. Our ability to answer this question can be helped by reading Managing to Learn, John Shook’s classic on using A3 thinking. In addition, I recommend reading Art Smalley’s “Four Types of Problems.”

What is the work to be done?

To help with operational improvement the choice becomes more situational (depending upon your environment.) However there are still some core texts. To understand the value stream I’d read Learning to See, to understand flow I’d read Creating Continuous Flow and for pull I’d read Creating Level Pull. If the problem called for looking at the supply chain Seeing the Whole explains the key concepts and questions to pose.

How do we develop capability?

Less has been written around capability development. However the Toyota Way Fieldbook by Liker and Meier is a good start as is the very practical Training Within Industry Workbook by Graupp and Wrona.

What leadership behaviour and management system are required for lean?

Reading around the Lean Management System and the Leadership Behaviours required becomes potentially more tricky. In the first instance I would re-read Managing to Learn. I’d also take the opportunity to go back to some source materials by reading Taiichi Ohno’s Toyota Production System, beyond large scale production book, Shingo’s Study of the Toyota Production System and Deming’s Out of the Crisis. However I’d also take a look at the brilliant work of Edgar Schein on the subject of Organisational Culture and Leadership. I’d collect insights from Jeffrey Liker’s latest book on leadership – Developing Lean Leaders at all Levels. Finally I’d delve into Learning to Lead, Leading to Learn – lessons from Isao Yoshino, written by Katie Anderson.

What Basic Thinking, Mindset and Assumptions drive this change?

A number of the texts already mentioned contain basic thinking. That is, the assumptions and mindset that underlies the entire system – and drives the transformation. This is about the basic beliefs we, as individuals have about the way the world works. These beliefs and mindset constitute the culture of the organisation. I’d add a few more books here – Kaizen Express, Lead with Respect by Michael Balle and Gemba Walks as there are some great chapters on subjects such as purpose and respect.

Of course such a list will always spark debate. That’s where dialog with my sensei comes in. We were discussing opinions and countermeasures. My sensei remarked that some people (whilst they would not necessarily recognise this) are “either – or” people. That is they choose one countermeasure – either A or B. It’s their opinion or your opinion. Effective problem solving requires people to evaluate “both” viewpoints or multiple countermeasures. This approach always beats “either – or” thinking.

The Best Lean Books are Useful but not Sufficient

This insight prompted us to develop countermeasures to share knowledge and developing understanding in different ways. Books are useful but not the only countermeasure to use in this step of capability development. In today’s digital age the webinar, apps and websites can be an extremely effective part of your portfolio. We have been experimenting in the following ways. Firstly, with the development of learning processes. Secondly, developing our Lean Learning Journey platform online. Thirdly, with a four level learning method – knowledge, understanding, being capable, being able to teach and coach others. Fourthly, with physical materials that help folk learn more effectively.

One size doesn’t fit all, but be sure to seek out the best lean books as part of your lean learning journey.

-

Creating Continuous Flow£48.00

Creating Continuous Flow£48.00 -

Managing to Learn£44.00

Managing to Learn£44.00 -

Creating Level Pull£48.00

Creating Level Pull£48.00 -

The Machine that Changed the World£7.00

The Machine that Changed the World£7.00 -

Lean Thinking£7.00

Lean Thinking£7.00 -

Learning to See£46.00

Learning to See£46.00

To see all The Lean Enterprise Academy’s learning materials, visit our Shop.

To purchase these books in North America, check out The Lean Enterprise Institute’s Book Store