The Lean Transformation Framework

Are you trying to transform your organisation (or at least part of it) to solve your business problems or close performance gaps? The Lean Transformation Framework is the starting point to help you apply Lean Thinking & Practice to your unique situation.

Learn what the Lean Transformation Framework is by watching our YouTube video created by our Senior Lean Coaches.

The Lean Transformation Framework shows you how you can align organisational purpose to create more value for customers, whilst developing people at the same time.

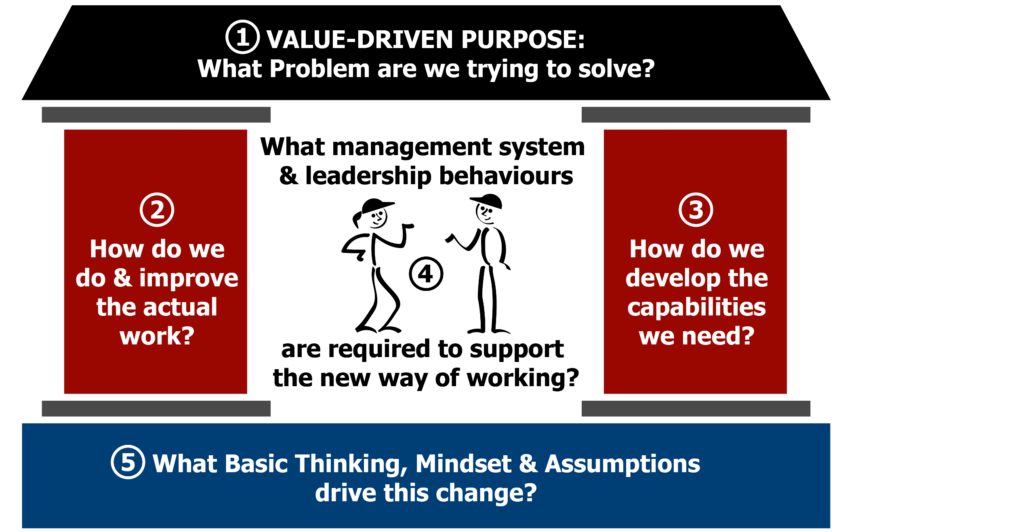

To explain Lean transformation we’ve borrowed the house metaphor from Toyota. The house comprises foundations, two pillars and a roof. Many organisations that implement Lean are aware of Toyota’s Production System House – and many firms have tried to emulate or build their own versions – often by copying the elements. However the Lean Transformation Framework is very different in it’s intent.

The framework we present above is not a prescription. Instead it is a series of questions, not answers. Conducting transformation is “situational” – that is, the work is not a prescriptive, one-size-fits-all solution, but instead is about taking a balanced view of Purpose, Process, People and Problem Solving.

The transformation framework entails transforming in five fundamental dimensions, by addressing the following high-level questions. The questions are “fractal”, and should be asked at different levels: for a supply chain or supply network; for a whole single organisation; or at a functional, departmental or individual level.

Conducting transformation is “situational” – that is, the work is not a prescriptive, one-size-fits-all solution, but instead is about taking a balanced view of Purpose, Process, People and Problem Solving. The transformation framework entails transforming five fundamental dimensions, addressing the following high-level questions.

1. What is the “Value Driven Purpose” : What problem are we trying to solve?

If we understand this we can ask “What problem we are trying to solve?”

More specifically this is defined by asking:

- “What is the purpose?”

- Of the organisation?

- Of the activity or process in question?

- “What is the problem we are trying to solve?”

- What is the gap in performance?

- What is the gap in capability?

- “What is the organisation’s capability for change?”

- At each level – senior management, middle management and front lines and horizontally along the process.

- At the system level and at individual point level.

2. How we do and improve the actual work?

Our approach is always to start with the value creating work for the firm, function or individual. Here we are asking:

- What is the work to be done (the process?)

- At either individual (Standard Work) or system (value stream or total enterprise) level.

- What is the current state?

- What do we want or need to achieve – a future state or target condition?

- What are the steps and experiments we need to undertake to achieve the future state?

3. How do we develop the capabilities we need?

In addition to designing a good process we need to develop people in two dimensions. Here we ask:

- What capability is required to be able to do the work ?

- What capability is required to be able to improve the work? – Developing kaizen mind and systematic problem-solving capability.

- Kaizen mind, challenging spirit – never-resting, always challenging

- Problem-solving capability – what is a “problem” and what is your problem-solving process?

4. What management system and leadership behaviours are required to support the new way of working?

The design of the management system and leadership behaviours is key to designing the work and developing the capability. They are intrinsic to sustaining / progress improvement. Here we are asking:

- What does the current management system look like?

- How do you want it to be?

- What leadership behaviours are required to achieve the shift?

Answering these questions engages leadership to:

- Understand the value creating work.

- Understand how the best Lean organsations use P-D-C-A to develop a system of Policy Deployment . (also known as hoshin kanri)

- Understand the difference between Lean management and modern management.

- Understand the role of the Lean leader.

5. What basic thinking, mindset or assumptions drive this change?

The final question challenges our basic thinking or assumptions about how we do things. Here we use the Lean Thinking truism that “it is easier to act your way to a new way of thinking, than to think your way to a new way of acting.

” Ohno described TPS as a “revolution in consciousness” and was developed not by grand design but by problem solving and designing experiments.

To follow these insights, a successful transformation is also about designing experiments – not implementing that which we “know” will work, but experiments where we can learn.

Your Next Steps – Learn More About the LTF

Complete our FREE Skill Level 1 Basic Knowledge course online for the Lean Transformation Framework . Or watch our LTF pay On Demand Webinar where our lean coaches talk you through it.

Read Our Blog Articles on Applying the Lean Transformation Framework

Seven Mistakes with Lean Transformations

Explanantion of The Lean Transformation Framework Questions

John Shook on Lean Transformations

Help your Leadership Team to become aligned and understand how to apply Lean

Develop your Leaders understanding on how to apply Lean Thinkng & Practice in your organsantion

We will run a 1.5 Day Lean Transformation Workshop for Leaders on site

Use our Skill Level 2 Teach Poster & Facilitation Guide to align and develop your own teams understanding of the LTF

Gain Access to All Our Learning Materials !

We are a non for Profit Organisation , support us by subscribing to our Leaning Platform . Here you will gain full access to all our Learning processes and materials that we are continually developing on many subjects