Problem Solving Questions and Answers

In our A3 Problem Solving webinars from 2021, we were asked some key questions around problem solving that we thought would be helpful to share with the Lean Enterprise Academy community. Throughout the article are some useful learning materials based around A3 problem solving. There are 17 areas discussed in this blog, if you’d like to find out about a specific area, please click on each one listed below:

1) Understanding there are different types of problems

2) Do you need to develop your problem solving skills first?

3) Dealing with organisational resistance to problem solving

4) Using the right problem solving method

5) Toyota Kata verus Practical Problem Solving

6) Capability comes from Learning by Doing

7) Firefighting without standards is a circle of doom

8) Learning Problem Solving takes time and effort

9) Developing Senior Leaders Problem Solving Skills

10) Avoid Jumping to Solutions Culture

11) Sharing LEA’s Learning Processes & Materials

12) Training vs Learning by doing

13) Why Re-training isn’t a good Countermeasure

14) A3 versus DMAIC problem solving

15) How to share learning from problem solving

16) Why Show Your Problem Solving Story on an A3

17) Leaders as teaches and coaches

1) Understanding there are different types of problems

“Are there detailed definitions for each type of problem available, 1, 2, 3 & 4?”

David Brunt:

Here are two articles that are on the blog both of those around that subject;

https://www.leanuk.org/problem-solving-methods/ – History of problem and the different methods that have been used over time.

https://www.leanuk.org/four-types-of-problems/ – Much more specific to your question and goes into the four types of problems.

I recommend that you do a bit of reading. Art Smalley’s book does a great job of describing the 4 types of problems:

- Type 1 the troubleshooting

- Type 2 GAP from standard

- Type 3 Target Condition

- Type 4 Vague/ Open ended

-

Four Types of Problems£42.00

Four Types of Problems£42.00

2) Do you need to develop your problem solving skills first?

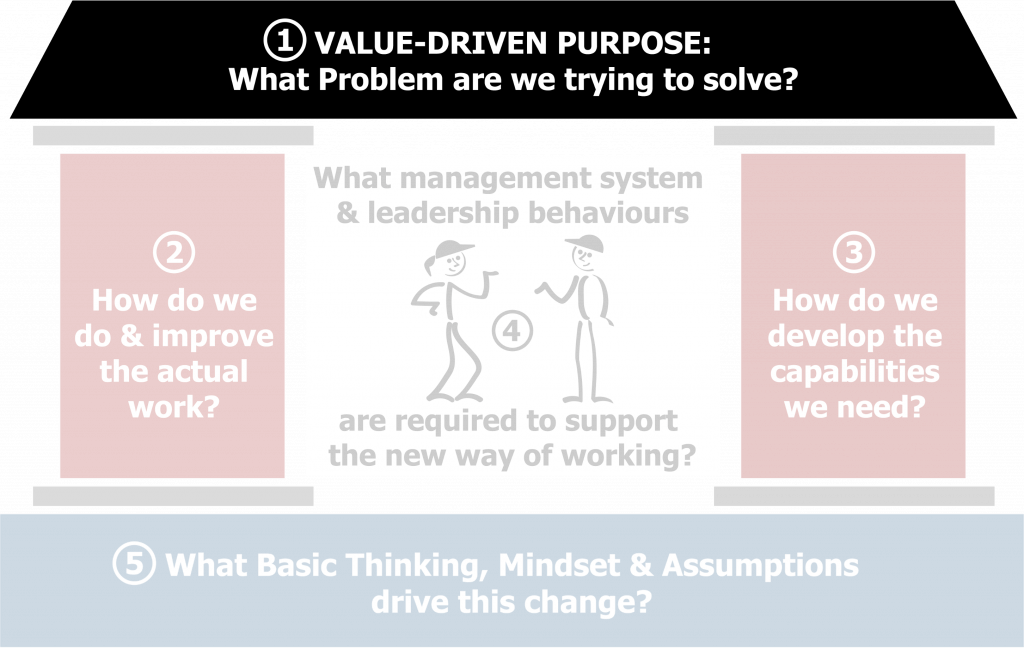

“Referring to question 1 of the Lean Transformation Framework (what problem do you need to solve) – do you need to develop problems solving skills first?”

David Marriott

It’s what we advocate because the first question you are trying to answer is “what problem are we trying to solve?” So you need to develop that capability initially at the beginning of your Lean Transformation. As I mentioned that was the part of the reason why we decided to put problem solving as the first module on the learning platform.

David Brunt:

Just to add to that the Lean Transformation Framework is a high-level set questions to ask about introducing lean, deepening lean and continuing to do lean in an organisation. Right at a senior level in an organisation the first piece of it is thinking through that value driven purpose “why is the company here?”, “why does it exist?” and “what value does it actually provide our customers?” Which is the first principle in lean thinking really. To do that effectively you need some of this problem-solving knowledge, but not everybody starts at that point.

It’s not a straightforward answer to your question and it depends on what the situation is. I would say if you can gain a good understanding and a good ability to be able to start the process of solving problems then of course you start where you biggest problems are, that might be in the work or it might be in particular customer issues that you’ve got. I wouldn’t say it’s linear.

3) Dealing with organisational resistance to problem solving

“Do you have any advice for convincing those within in the business that are resistant to the use of problem solving (those that have no experience or don’t see it as “their job”)”

David Marriott:

The best way to convince the leaders is to go and do to something that shows some results. Show what you can actually deliver by adopting that process and that activity and the results will speak for themselves. Our webinar presentation shows an example of this as well.

David Brunt:

Quite often problem solving is done by experts and all of our research suggests that what you really need to do is you need to get the line managers teaching their people the use of these types of activities, so the ownus then is on the leadership to be able to do that. It’s a key reason for simplifying the process to enable the line managers and the leaders to get comfortable with doing this type of stuff.

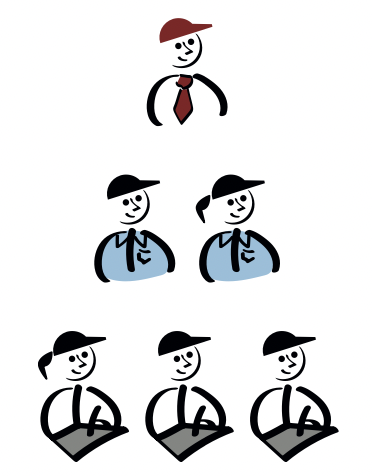

The simpler you can make it, the easier it is for them to become comfortable with it. Quite a lot of time (because it is a particular department’s job) particularly in larger organisations, you do find that line managers run away from it and they actually want the experts to come in and help them. What we’ve seen from the research that we’ve done is that the best organisations are actually developing that capability in their line managers to teach & coach others.

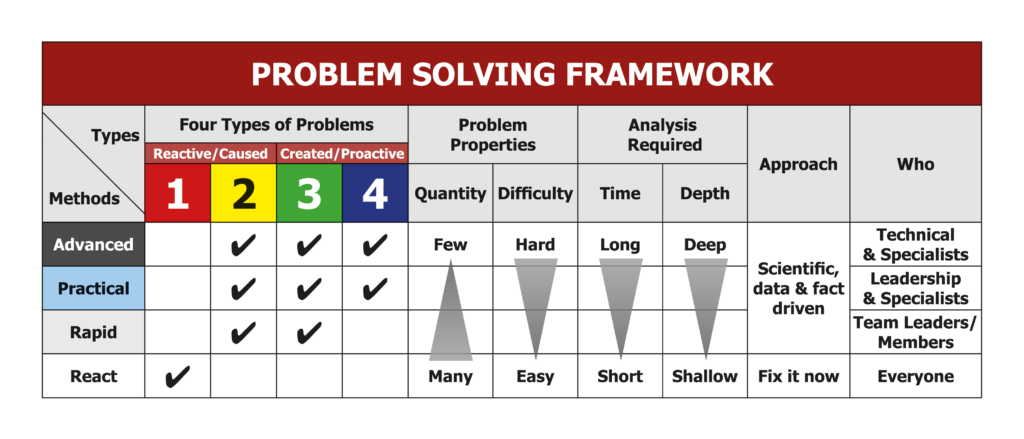

4) Using the right problem solving method

‘When would you start an A3 and when would you just solve problems by trial & error PDCA?“

David Marriott:

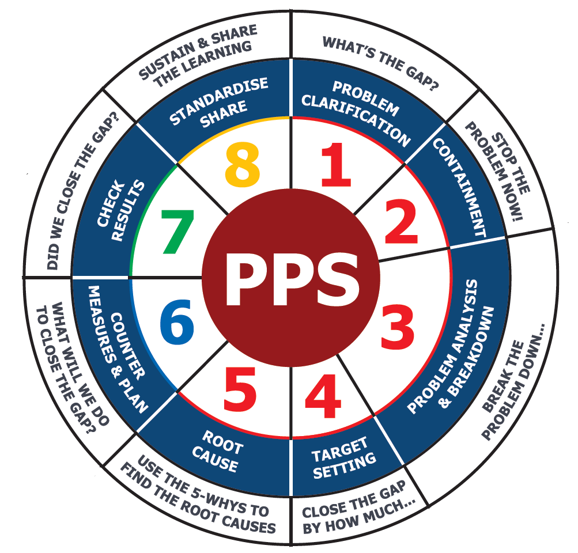

Good question. It really depends on where you are in terms of your level in the organisation, “it’s taking a sledgehammer to crack a nut”. Practical problem solving is really good for those business type level issues on a more professional level, whereas the rapid approach is more frontline leadership or maybe those smaller issues. There’s nothing clear cut and a few grey areas, but really think about the size of the problem, the level they are in the organisation and the capability to think about what kind of approach to apply. A3 is difficult and it can take a long time to go through problem solving, so again you need to be mindful of the time frame you have and how quickly you need to get to a solution.

Peter Watkins:

I suppose that links to another question that is “what’s the main difference between A3 problem solving and six sigma?” I was trained as a black belt as well and I only used it twice in 30 years. I would view it as the level of complexity of analysis that you actually need to do. With small simple problems there’s not much analysis needed and route cause is obvious.

The bigger and vaguer the problem, the more analysis is needed to break the problem down and understand the causes. It time it takes to do this, and the depth of analysis needed to understand the problem are the trigger points. For instance, when I did the six sigma project it was on laser welding. It had many variables and there were lots of things to analyse. This wasn’t a quick problem and we had to have a full dedicated team on it. However there are very few of those types of problems, usually around 90% of day-to-day problems with the work can be fixed through rapid problem solving with a simple 4 step approach.

5) Toyota Kata verus Practical Problem Solving

“Where does “Toyota Kata” play into 8 step practical problem solving?“

Peter Watkins:

Especially on the quick type 1 problems Toyota Kata is very good for first line team leaders to ask those simple 5 questions (the kata questions) to team members and get something practically done now. However, as it’s a coaching routine it certainly doesn’t go into the details of explaining the scientific method and thinking way need for more complex type business problems that a A3 8 step practical problem solving activity would address.

“Could you please reflect on how we can combine the A3 methodology with that method”

Peter Watkins:

I’ve completed my Kata training and I’ve done problem solving for a long time. Kata and the five questions are great for team leaders to do problem solving at that level directly with team members, whereas Practical Problem Solving requires a different level of coaching and thinking when you’re getting people to work on bigger problems. The kata approach is more practical based coaching and needs combining with the appropriate improvement methods such as Standardised Work or SMED etc. to ensure they are used correctly around achieving a path towards a specific target condition.

As shown in our problem solving framework for type 1 and some type 2 problems – Kata is good for these. But when you need to analyse things in a more complex way, using data and getting people to think about that situation and look at it from different angles, then I wouldn’t use the Kata approach, you need a different type of coaching. We have developed some methods to help with that , such as an evaluation method to look at peoples thinking for each step and to make sure they’re thinking way is correct.

We’ve developed these materials for leaders to use so they can coach people through their A3 better. So yes, a different set of questions and different answers are required than just using the standard five Kata coaching questions.

David Brunt:

If all you’ve got is those five Kata questions, then it’s the equivalent of having a hammer and everything just starts to look like a nail. You need to follow an effective problem solving method for the different types of problems. You also need to be able to stratify data, understand histograms and the basic seven quality control tools. We’ve got a nice set of evaluation criteria, which if you compare and contrast, it’s not to say that the Kata routine is cleverly packaged and it can get you so far, but it’s not really addressing the types of problems that you would use this method for.

6) Capability comes from Learning by Doing

“How do you teach & coach people to be good problem solvers?“

David Marriott:

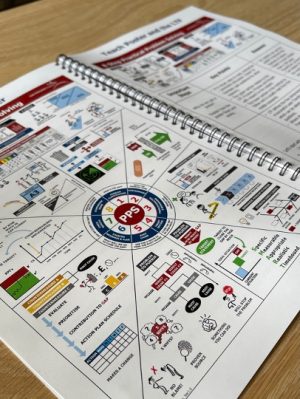

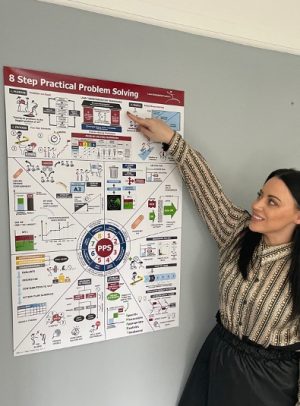

Follow the right learning process! We talk about management routines or leader standard work (in the webinar), so as I mentioned at the start LEA are developing better teaching materials i.e. posters and guides to make it easier for leaders to be able to teach others – so simple visuals and a key point explanations (rather then death by powerpoint).

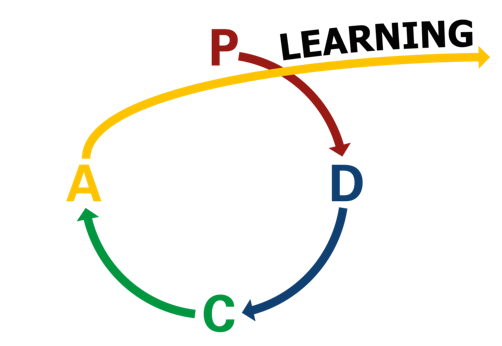

But really, it’s “when the rubber hits the road” by coaching people through an actual problem, “learn by doing” – is the best way. There is only so much understanding that you can gain from reading a book , taking a class or being told. What we found is that real learning happens from developing capability through coaching and doing real problems – so the learner can get real time feedback and adjust their approach P-D-C-A learning!

7) Firefighting without standards is a circle of doom

“Isn’t it that many reactive problems stem from having basics not right i.e standards in place or poor understanding of basic conditions?“

David Marriott:

Yes, that can be a symptom but again in terms of the analogy of having a flat tire, sometimes things just happen! In that case we just have to react to those situations. However, it can be a cycle of doom if you haven’t got the work standards in place, and you will therefore be forever firefighting and troubleshooting because the work gets done differently every time and new problems always then appear!

8) Learning Problem Solving takes time and effort

“It seems like this process requires a lot of time and effort. How big must have problem be to make it worthwhile? What do you do with smaller problems?“

David Marriott:

Yes, it does take a lot of time and effort. From my Toyota experience of going through the Toyota Buisness Practice training, the expectation was you spend at least 12 weeks on your problem. In our experience it is roundabout 12 to 14 weeks and the example in the presentation was around that kind of time frame, but obviously prior to that would have been through the case study as well, so at the time that was a day’s training. So yes, it does take time but if you want to develop that level of capability to be able to hand off people to teach and coach others then you need to spend that time doing it.

For the smaller problems as we mentioned there are some issues which you can just react to or you go to the four-step rapid method. So, they address those day-to-day performance type issues. Whereas A3 8 Step practical problem solving tends to tackle those medium to longer term business type issues, where you’re going to have a slightly bigger impact than just maintaining performance and actually look to make some larger improvements or some step change.

9) Developing Senior Leaders Problem Solving Skills

“How do you develop the necessary problem solving skills in the leaders? particularly the higher levels”

Peter Watkins:

Peter: We’ve had that difficulty for many years. First of all, leaders do actually need to understand the scientific side of the 8 steps and they need to learn that in a safe way. Toyota originally started that through getting people to practice on different levels of case study, from a very simple level case study, to a more complicated one. So that’s the initial learning. Then they practiced that and learned by doing A3s themselves to become capable – to be able to do it themselves.

Developing Senior leaders teaching and coaching skills is another set of issues. We do this through fun/safe learning by doing exercises, such as putting on the wall an A3 that’s got problems with it. We asked the leaders to coach people to get that A3 up to the next level. We taught them the types of questions and ask, how to ask questions and how to lead correctly around it as well using the situational leadership model.

We’ve developed several short sessions and models and thinking ways to help people simply lead the practical problem solving teaching and coaching well. That session usually takes probably about three to four hours of practice and involves coaching and presenting to others. That usually is enough for people to then start teaching and coaching The real practice is then teaching and coaching two other people through one-on-one coaching, in short burst sessions through the steps and following the process.

10) Avoid Jumping to Solutions Culture

“Do you have advice on how to start A3 problem solving in an organisation where jumping to solutions is normal behaviour and expected even from the management?“

David Marriott:

You’ve got to get a good coach! And you’ve got make them follow the process. Again, in terms of organisations we’ve done this with, it tends to be the default behaviour and you’ve got to rain them back but explain the reasons why you don’t want to jump to solutions and you want to see it through to get a sustainable result. What you tend to find is if we jump to conclusions without actually understanding the problem, we don’t find the root causes and then actually we end up solving the same problem again and again…And again.

Peter Watkins:

I went in one manufacturing plant where they had 300 extra people in their manufacturing plant due to the fact, they just stopped at containment stage and never really resolved their problems, instead they just added more people cost in to contain it.

Then when you say you’ve created the loss because this is our waste, then you’ve created a loss of X amount of money because we didn’t solve this problem and we just embedded it into the work. Get the waste on your radar, go spot it and then with senior management especially say we’ve got losses here due to X and we’ve never solved it to the root cause. This will certainly get their attention.

11) Sharing LEA’s Learning Processes & Materials

“Assuming an organisation would want to go and utilise this problem-solving framework, to create capability in their own organisations, if you do the course can we share the materials internally and start using them? Or do we need to licence them?“

David Brunt:

What we’ve tried to do with all the materials is make them affordable. We’ve looked at everybody else’s material and content and we know what people are doing in companies and the continuous improvement folk that spend a huge amounts of resource actually developing their own stuff! So, there’s a massive opportunity in all of that wasted time that people spend trying to develop their own things. What we’ve said is the more of it you are able to give to people, the lower the price can be.

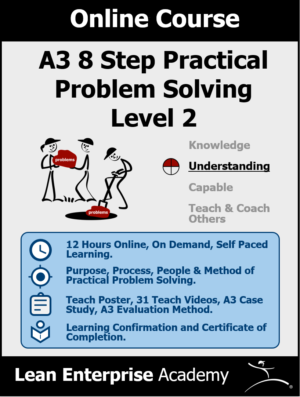

Peter Watkins:

When it comes to coaching people to skill level 3 (Capable) there’s only a few of us and there’s not enough coaches. If you’ve got people at that are at level skill level 4 (Teach & Coach others) they can use and follow the process internally themselves.

David Brunt:

The real problem that we try to solve is “how do we get more people doing lean the right way?” That’s the big problem. To answer your question we basically have tried to make these materials really accessible and really cheap. What we want people to do is to not to just crib them and copy them and then use them internally, but if what they say “that is so cheap just buy them”. By doing this it helps in two ways; you’re funding us to be able to create more and at the same time and you’re freeing up your own time because you can spend more time developing others by creating and adding value.

12) Training vs Learning by doing

“Some Lean Coaches just want to teach capability into teams, not go and solve problems with them because that just limits the bandwidth of what we can do.“

Peter Watkins:

We don’t solve the problems for people we only develop them and that’s the key. But they get a good result at the same time. We don’t get faith by management from just training alone so people want results, and this delivers both. Usually, the management are quite happy because you can see a result and we involve them in the process even when the senior management comes to the report out, they can see the benefit of it.

At skill level 2 we have an online problem solving course that you walkthrough over a number of weeks. What’s very attractive to me and the organisation is to be able to do it remotely over something like teams and we can deliver that internally with these capable people.

David Brunt:

We did this process with a partner organisation. Peter and I are spending our lives on teams with their full management team across 5 sites and we coach the senior managers on those 5 sites in teams of 3-4 people. We taught on set days and then gave some homework to the teams.

Peter Watkins:

What you find as well is that there are positives and negatives for coaching online. We’ve found it’s a lot better as it’s like you would do normal coaching, short bursts learning at one step and then getting feedback. That’s how people are learning, not through just doing a 4-hour training course that’s for the basic knowledge. The real learning is through true constant feedback and adjustment to their approach and that’s why just doing an hour a week is manageable for people, because they’ve got to balance that with what we’re doing on a day-to-day basis.

13) Why Re-training isn’t a good Countermeasure

“People regularly go through problem solving and then say people need retraining or are told not to make the mistake again. Should I stop beating them up as in some processes there is an opportunity for error proofing.“

Peter Watkins:

It’s a common thing we have to tackle when we are getting people to think about these more deeply, retraining – that’s usually there. What that means is we haven’t done the “whys” properly, we haven’t understood what’s gone wrong in the system or the process to understand that. A lot of the time (especially on business processes) things aren’t clear, the standard isn’t clear, you could not have a standard in place, or the roles and responsibilities aren’t clear. Retraining is ok if you’ve changed the standard – we need to retrain people in the standard. But that’s just part of the countermeasure make up. It shouldn’t be part of the root cause analysis that’s for sure.

David Marriott:

There’s either something wrong with the training process or the something wrong with the standard work, that’s why the people making the mistakes. We don’t want to blame people but that’s what’s wrong with the process.

14) A3 versus DMAIC problem solving

“How do you see this process differing from the DMAIC problem solving method?“

Peter Watkins:

Originally, I got in an organisation that adopted six sigma quite early, but we’d already adopted the 8-step approach, so I’ve seen both sides of the coin. From my experience I was trained as a black belt and used the method probably two or three times maximum in my 30 years. The reason for that is most problems aren’t that complicated, they don’t have that many variables that you need to start analysing it at that level. I’ve used six sigma to solve complicated problems on welding and jig fixture heat analysis where there are many variables.

I would say 90% of (business) problems you can use eight step approach. More importantly most problems are even simpler than that, we shouldn’t just be using 8 step, we should be using rapid 4-step problem solving it’s even simpler. For 60-80% of problems, you could use the 4-step approach. The difference is the level of analysis that you would do, and Toyota don’t really use six sigma for that they just do more analysis in Step 3.

15) How to share learning from problem solving

“Any examples of how to systematically share the knowledge?“

David Marriott:

We get asked this when we do the training quite a lot about the sharing. From my experience at Toyota the expectation was on the individual, it was your responsibility to disseminate that knowledge. There wasn’t elaborate systems or processes in place, it was down to you and that was the expectation. Your manager would be asking “what have you done to share this?” Or “what are your plans?” A lot of what we advocate is the individuals go and take responsibility, the sharing is more action based.

- What are you going to do?

- When are you going to do it?

- Who’s going to be involved with that? what’s the status? is it open or closed?

- And have you finished that?

You can deposit them and put them into various repositories with any companies, but again you still need a process around people either going into that or some method to make sure that knowledge is liberated in the organisation. It just becomes a library at the end of the day. It’s really about taking that responsibility to do that.

Peter Watkins:

As Dave as said there it’s the investment. We have been in organisations where there are 165 manufacturing sites so it’s quite hard to share that. But I think it’s leadership also understand the investment in that, so sending people to share.

A lot of good sharing is done when people talk through it, present what they’ve done and talk to the right people. You need to give people help to talk to the right people in the organisation. I think from my experience just putting things in a database doesn’t really work, you’ve got to make it live. You’ve got to find a process to do that and there are many different ways you can do that, but also that is an investment. I think if the benefits are there, then it’s really worth the investment of sharing it properly with people.

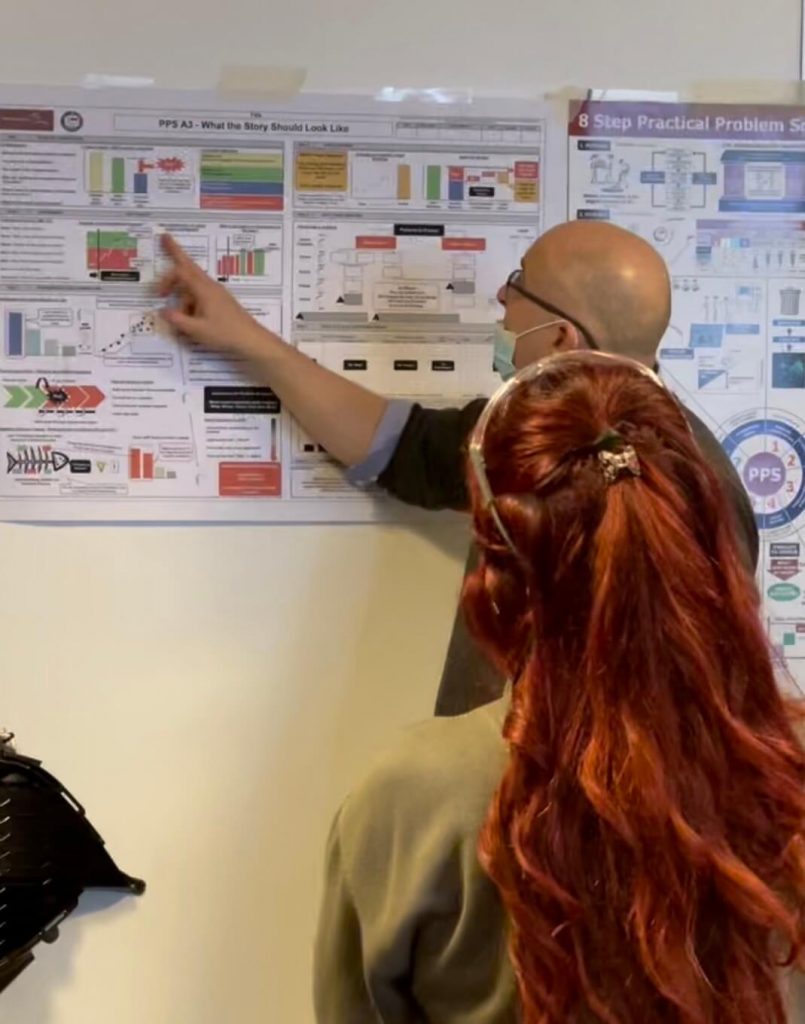

David Marriott:

That’s part of the reason why when we do the on the on-site training it’s very low-tech high involvement affair. It’s people standing around a piece of paper, but really it starts that discussion and interaction and also makes sure that people are listening and paying attention as well. There’s no easy way around it you’ve got to physically do it.

Peter Watkins:

Yes, it’s always better. Some people have started to use video to explain their A3 and share it out that way. From my experience burying it on a database isn’t probably the best way to do it. You need people to talk through it and answer questions. People want to know about how we can apply it to their situation.

16) Why Show Your Problem Solving Story on an A3

“Would you recommend using an A3 template?“

David Marriott:

It’s a good start. We do provide that as it’s just an A3-sheet paper with the steps in an empty box. What we advocate again is people not getting hung up on “the box has got to be this size”, it can flex and change based on the problem that you’re solving. In terms of providing a template to follow the process in the steps, that’s a good idea. But again, in terms of “it’s got to fit in that box” and “it’s got to be that size” that’s not something we’ve advocated, it’s situational and it depends on the problem. Following the process is the key.

Peter Watkins:

It certainly helps having a structure with the learning at first, then as people get better, we can free that up. If you don’t provide the structure people will struggle with it, but the danger to that is it becomes a tick box, or a form filling exercise which it’s not. And that’s why the evaluation as Dave mentioned is key, to check that people have got the right thinking and they’re not just trying to fill the box.

David Marriott:

What a good A3 looks like – we try to populate what that with expected content so that people know when they face something with a blank box, you’ve got something to refer to, but it’s applying it to their situation, and that’s where typically people need coaching and support.

Peter Watkins:

Also, with the learning process that we’ve developed, we will not let people jump ahead. We don’t let them complete a full A3 and then find out the step one was wrong. So the way that we do it is one step at a time and get the thinking done well before they move on, and they have to achieve level 3 in the evaluation on that step or as near as possible to that before they move on to the next step. Then people’s adjustment is better and they’re not wasting time filling in six steps that are no good.

17) Leaders as teaches and coaches

“A key role in problem solving is the “leadership should become the teachers and coaches”. Those businesses that you’ve worked with, would you be willing to say as a percentage how many adopt that approach?“

David Brunt:

The ones we work with is what they have to do, so they don’t have a choice! But having said that we’ve also done a lot of research and work over the years where we’ve taught teams i.e., continuous improvement teams. If I look at our database, a large proportion of it are involved in doing continuous improvement in some form or other. That’s why they are on our database because they want to know about better ways of doing that type of work. Over the years we’ve educated them in all kinds of techniques originally, then dealing with management issues more laterally.

Then as we’ve gone to do this research around the Lean Transformation Framework and what the best companies are doing, it just highlights the need to actually build this capability into the line. I think a lot of continuous improvement people get very concerned by that because they would say “I’ll be doing myself out of a job “, but actually that’s not the case because if the primary purpose is to strengthen the line capability, then actually you end up with a much higher quality of problem-solving capability, which then means that you actually get much richer work to do.

Upcoming Webinars on Problem Solving

A3 Problem Solving Webinar

The Lean Enterprise Academy is hosting its A3 Problem Solving webinar on the 23rd March at 3:30pm. If you’d like to learn more about the webinar click here.

On-Demand Webinar

We offer an on-demand version of the webinar which gives you access to a one hour recording. In addition you’ll be able to download the materials used in the session, which includes a teach poster, the presentation slides, and transcript.

All the webinars and courses available on our website are based around the Lean Transformation Framework. We are also developing materials every month. If you’d like to access all of our learning courses and on-demand webinars, we have made them all available on our Learning Platform Subscription for a low yearly cost of £119.99 for individuals (for Enterprises contact us here). Learn more about the subscription here.