How the Best Organisations Develop Capability.

We have just launched Practical Problem Solving on our Lean Learning Journey platform which follows one of the most important pieces of research we have conducted. Understanding how the best lean organisations develop capability. In summary the best:

- Align capability development to the current and future work to be done to meet organisational and customer purpose.

- Base development on “need” and encourage pull not push.

- Realise that skill cannot be developed in a classroom alone. Theory is important, but lean is a practice led activity.

- Develop a “plan for every person” rather than focussing on a select few people.

- Develop capability through line management via coaching from capable superiors, rather than by employing internal or external “experts.”

- Have processes that develop skills rather than processes that just create training.

Spreading the use of Lean Thinking.

When Jim Womack and Dan Jones created their not for profit organisations (The Lean Enterprise Institute and The Lean Enterprise Academy respectively) they did so to spread the use of lean thinking and practice. Jim wanted to write down the Toyota Production System in a “usable form.” To inspire others to become the Toyota of their industry. It was a noble initiative that produced some of the best “how to” workbooks on lean.

We also developed workshops. Many were aligned to the content of existing or soon to be released publications. They provided awareness of the techniques, basic understanding and discussion around the challenges of using such methods. However, capability cannot be developed in a classroom alone. The classroom is for awareness and basic understanding. One of our countermeasures was to conduct action research with organisations to truly develop capability for people to be able to do and improve, themselves.

Workbooks, workshops and coaching have helped hone capability development over several years. However, each time I looked at our activities and compared them to our purpose, I felt we were missing an opportunity. The world of work has changed considerably since the late 1990’s when the first workbook “Learning to See” was published. Then, the internet was in its infancy. Knowledge was disseminated through books and articles, talks and visits. Not found via a google or YouTube search.

The Lean Learning Journey.

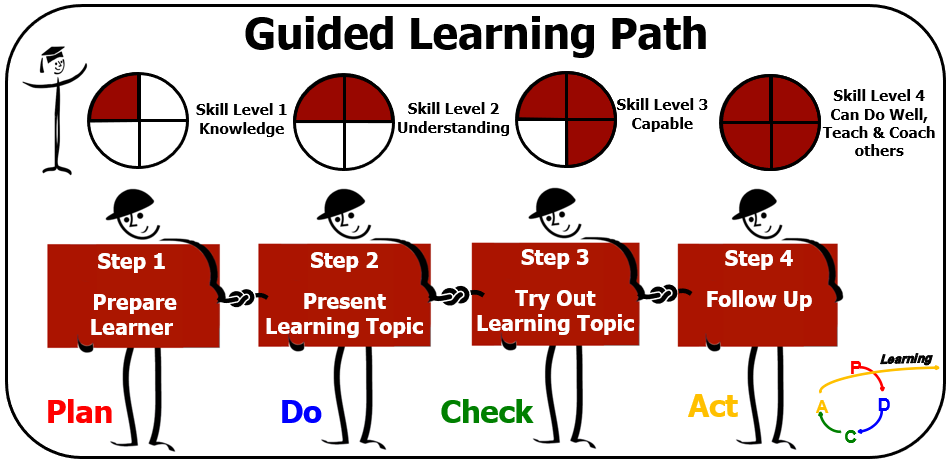

Remaining relevant, particularly for new generations of managers that have had access to new ways of gathering knowledge is a major challenge.To close the gap we’ve developed our Lean Learning Journey process. The underlying thinking used is about supporting individuals and organisations to learn to do lean themselves. It employs Two four step processes (based on PDCA.) The first focuses on the level of capability the learner needs – from knowledge, through understanding, being capable and being able to teach and coach others.

The second process (also consisting of four steps) is the capability development process itself:

- Preparing the learner

- Present the learning topic

- Try out the learning topic

- Follow up

To help you learn and apply Lean Thinking to your work, we are compiling free and paid resources into our “Lean Learning Journey” platform. It’s a Learning Management System. We are putting key subject materials in one place for our community. We want to reduce your non-value added searching time, providing the right information at the right time and at the right place so you and your team members can develop thorough knowledge of Lean Thinking and Practice. By putting together the “vital few” articles, thought pieces and handy hints we hope to encourage the lean community to become effective learners.

First Material: Practical Problem Solving.

The subject for the first free material is Practical Problem Solving. The Level 1 course is available HERE.

For those wanting to develop their capability the Level 2 Practical Problem Solving course is available HERE. We chose Practical Problem Solving as it’s the fundamental skill all lean thinkers need. The material consists of:

- 30 Teach Point modules.

- 28 Videos.

- 10 “learn by doing” exercise modules.

- 8 Learning Confirmation Quizzes.

- 12 supporting material downloads – A3’s examples, A3 Evaluation guide & visual, 3 Visual Teach Posters, Teach Poster guides and a Problem Solving Tools leaflet.

Development of our Lean Learning Platform will continue in two dimensions. We will add more on-line learning materials in the form of subject areas to the Lean Learning Journey and we will add processes to enhance the development of capability.

We’ve collected feedback from user groups as we’ve been developing the platform so both individuals and organisations benefit from the materials. Individuals have told us how comprehensive the material is. They like the flexibility of learning at their own pace. In addition, they like the wide range of learning styles on the Lean Learning Platform. Internal teams have told us how the material has helped them reduce their time training and use it to coach, helping them create more value in their organisations.

To conclude, the ultimate goal is for organisations and individuals to develop a pathway to learn or enhance their current learning themselves – thinking of learning as a continuous process rather than an event driven activity. It takes us closer to our purpose of providing lean learning better, faster and cheaper.