This article is a transcript from Sharon Visser’s How to Develop a Lean Mindset for Change keynote at UK Lean Summit 2023 on the 19th April. Sharon is a Lean Coach and Author. Her inspiring story ‘Lean Houses for Dragons is available to purchase as a paperback copy here. If you would like to watch this keynote, please watch the YouTube video below.

Introduction to How to Develop a Lean Mindset for Change

Every continent of the world has stories of dragons. Wherever these mythical beasts lived, these ancient legends endowed dragons with great power, life changing power. In some cultures, they are creative and protective and in others all-consuming and destructive. They reflect the fears and the aspirations of the storytellers and the times they lived in.

The dragon I speak about is a metaphor that represents the joint response of the people doing the work, to the leaders influence on their behaviour. Every organisation has a dragon. Every organisation can use lean thinking to harness it. Like dragons, the people doing the work have the power to create or destroy. They too reflect the fears and the aspirations of their storytellers. My dragon is called in Ngami.

In 2013, lean thinking came into my life and with it I could write about a dragon in my care. This dragon lived in a remote part of Africa waged between the Kalahari Desert and Okavango Delta. A Toyota dealership operating in a challenging environment plagued with a lack of skills, constant power failures, water shortages, distance from suppliers, high ambient temperatures, and challenging road conditions.

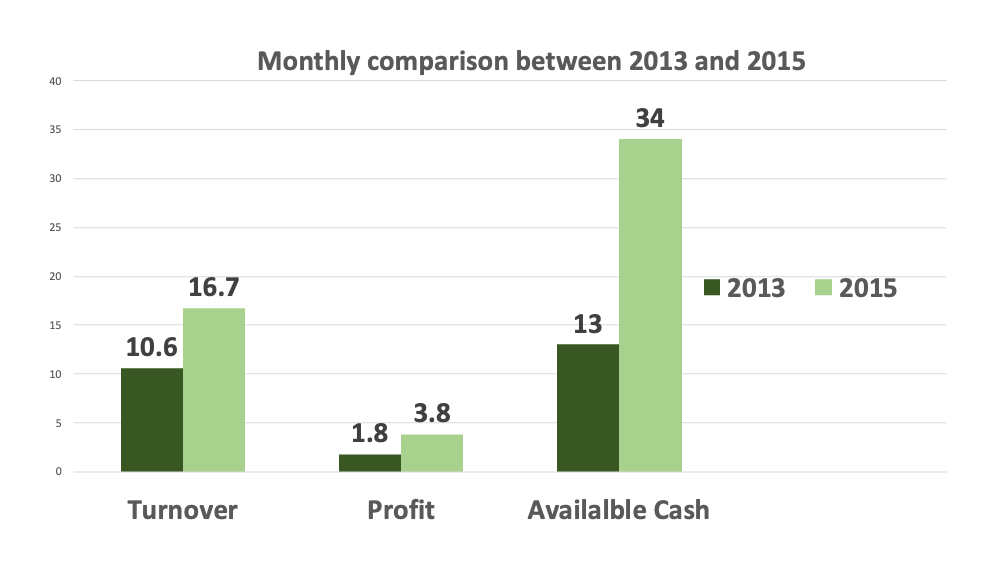

The global competitiveness report for 2013/2014 showed Botswana’s poor work ethic as the most problematic factor for doing business in the country. Lean thinking overcame all these challenges and provided us with improvements that were beyond anything we could have imagined. Below you can see the measurement of change (not just because of the finances) and how it has changed over a period of two years, and it reflected in money.

The Biggest Change

But for me the biggest change was with engagement. I had the joy of engagement with the people I worked with it changed everything. Their self-worth improved and they were able to grow as people and they were able to find the joy of problem solving, and the joy of having control over the problem solving. This changed everything for everybody, especially me. We started learning about lean from David Brunt with Terry O’Donoghue the COO of Halfway at the time.

It started with Dave and Terry coming for a week during training with us. Out of our 98 staff, 25 of us went on the training and it varied from the higher senior roles in the business to the guy that was running the wash bay because everybody got a chance. Noting that the person running the wash bay was basically illiterate, so we did all our training together.

It was during this time that we learned about the Toyota house, or the lean house and we were introduced to the halfway house which was the new company that had purchased us. At the top of their house was mobility. Mobility was what we had to do. We had to give our customer mobility as soon as we possibly could, in time and correct.

From the start I knew that getting our people to change would be hard, very hard. Our team started with the challenge of fear they were afraid of the change. They were afraid of having new ownership. So, when people become afraid, they challenge, and it came to a point of passive resistance and at times militancy within the technical team.

People have asked me how I eventually got them to change. In a nutshell, I did not change my employees, I changed myself because I’m the only person I can have control over. I changed how I responded to the problems and to their fears and then they changed. I only changed when I learned to reflect on my responses and control my responses and I changed because I had to.

There wasn’t really a choice but to change otherwise we would not have been able to achieve anything. Lean gave me a guideline on how to achieve this and lean thinking carried us through until we could accomplish what we did. As we were having so many difficulties with the passive aggression and the militancy, I recognise that our human resources were our first place to focus.

So, with my HR person next to me who had also been on the training, I bought in every staff member by themselves into my office and we addressed their fears. what were they afraid of. Then I told him about what we had to do. I addressed where we had to change, how we were going to make the changes, and most importantly why we had to change. It was important to recognise that this was a small town, and these were people that had families to support. They couldn’t afford to lose good stable jobs, but they had to come along with me on the journey.

Addressing Fears

The best way was to address their fears and let them express what they were frightened of. You would be amazed at how easy it was to remove some of those fears, they were small fears, little things around their life. But I made it very clear that change would still have to happen and the whys. It was to keep their jobs, to keep them looking after their families, for having a better day at work because these systems could help them. It was the first step towards getting them on board.

Then we worked very hard in making the work visible using all the lean techniques we possibly could and designed some of our own by making the work visible. We created visuals that you could stand next to and talk about, but also, we started to introduce single lane flow so we could see the problems and address the problems with the people doing the work.

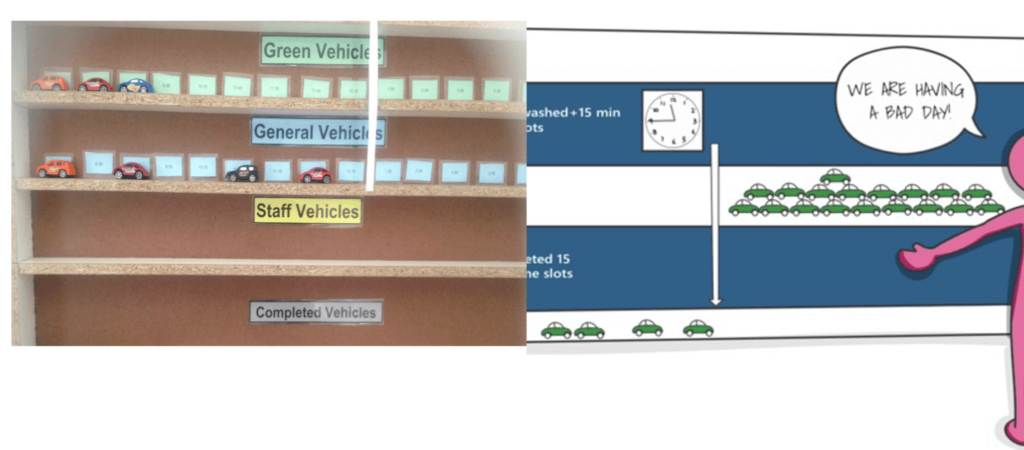

The image below is a visual of our wash bay for wash bay employee who is illiterate. So, getting him to fill in documents was not the greatest idea. The wash bay was external and almost in the sun so we could get vehicles dry. It was an open area and we had lots of dust and wind. So, by creating this visual we could see if we were ahead or behind.

Also, it wasn’t difficult to manage, they didn’t have to write anything. All they needed to do was move up the timeline and make sure that the cars were in the right positions on the other side the timeline. So, you can see on the timeline that they can see that they’ve got a pile up of work. This allowed them to not have to read anything, they could see. They could control it and it became our most powerful visual because I started to use it to see how well the workshop was doing as output is important.

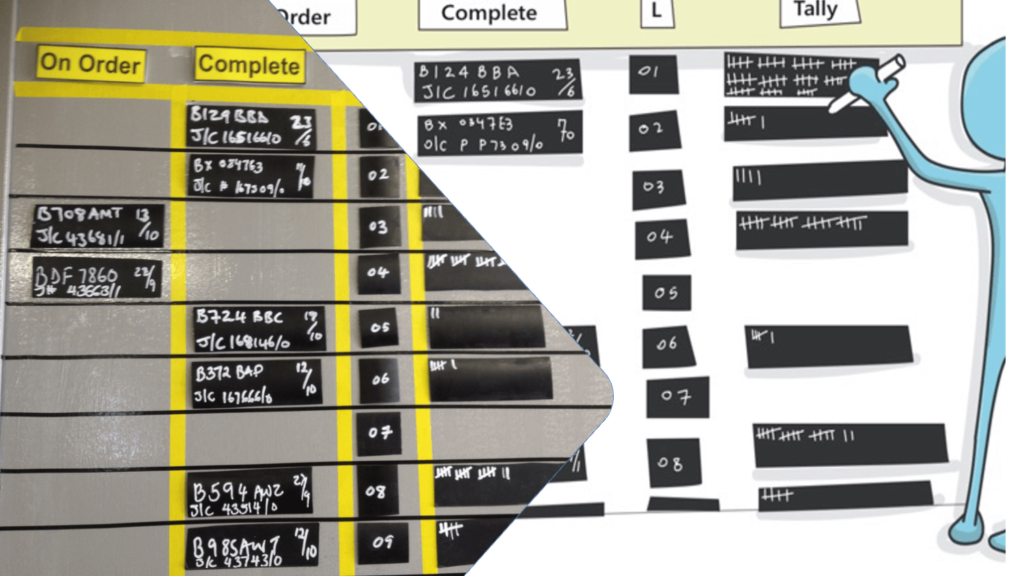

In our parts department 80% of our business came from government. They are big, complex orders. Getting paid for the orders required a long process. Even getting them fitted required a long process. So, we created a system for controlling orders in, orders complete, where they were, how many days (using a tally) they’d been in there.

In the Image above shows you can see there’s a top section with a very long tally, this was a government vehicle that had been in an accident. They couldn’t bring it in an we had to push and push to try and get them to bring it in. We could see and have the conversation at the board every day on the status of every single part that was coming in on special orders for customers.

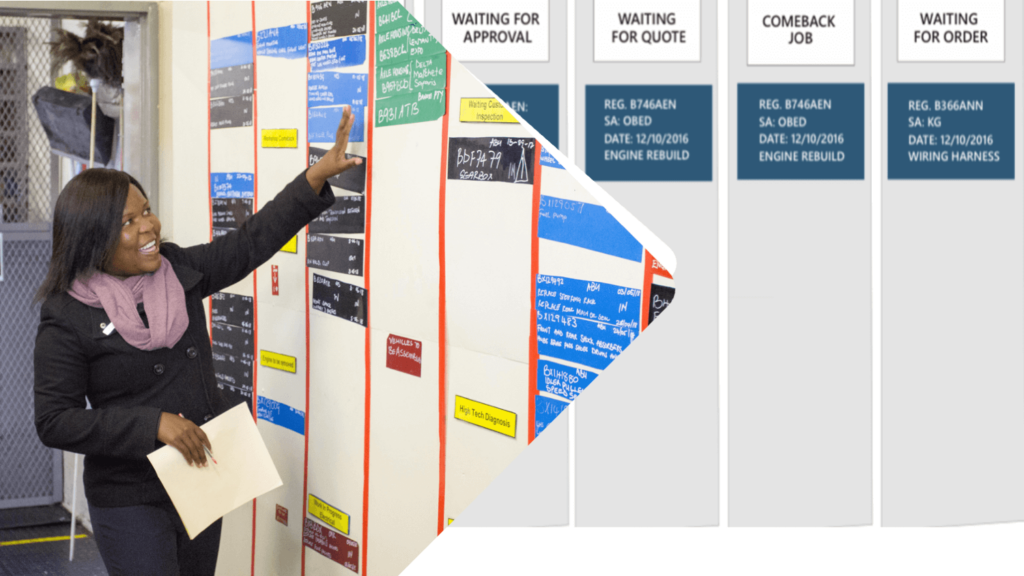

This picture shows our work in progress. We had a very large board with magnetic chips and the details of each vehicle and its status. We had a meeting every day at that board where we could talk about the work and move the chips and hand over responsibility within the department, from waiting to quote, to a comeback job and then back into the workshop to where it was being worked on. So, it created a place where we could stand and talk about the work with the people doing the work. And that was something with a daily huddle every single day, to make sure we were on top of it.

The visuals also made the daily gamma walks productive because we could see what was previously unseeable. A little bit like dressing the Invisible Man. We could start to see the shape of the business by walking and seeing the visuals. Something we couldn’t see before walking through, we could now start to see as we walked the gemba. It made the gemba talk to us. The gemba had a voice. and as we did that, we started to observe the work more because we could see.

We could also learn about the wastes, seeing the burden it puts on the people doing the work. Once one starts to see that burden, one can respond by making the work easier, simpler, and more controllable for the person doing it. Nobody ever argues about that. When we can make something, easier people want it to be easier.

Observing the Work

When we observe the work, we could document and grasp the current situation and do a GAP analysis giving us the problem to solve. And we did this with very frontline people in very simple A3 formats, so that they could start to understand the gap. We learned to reframe a problem into a gap. It was a very good day when an employee came to me the first time and said I have got a gap.

He didn’t say I’ve got a problem he said I have got a gap. It was a moment of change that came across everybody because he started to do it and then the guy who was working with started to do it. Then the employees talked to somebody else when they realised, they had a gap nobody shouted at them. Nobody said you’re doing a bad job. So, we could see and reveal all the problems they had doing the work.

Now we could do a gap we could start to use the A3 report and find countermeasures and follow them through during the Plan-Do-Check-Act (PDCA). For some problems on the front lines, it was a very simple A3, a very simple PDCA. Then other times it required more teamwork, more effort. But by doing it with a team everybody learned how, and everyone learned not be afraid and to celebrate the problem.

At the same time, they learned to celebrate the failure because it was an opportunity to learn and to grow. When we had problems to solve, we improved the work and then we started with Kaizen. It was Kaizen that grew the people, that built their self-esteem. Because the people solved problems found solutions.

They were cheered when they managed to find some radical little improvement with the work and make it better for everybody. Thus, they were given the opportunity to grow. That is what people want at work they want to be able to grow. We created an environment of growth. They want to know their managers care about them and want to know their managers want them to grow. Research has been done by a South African HR team. This HR team went all over the world, and they collected information. The predominant answer to what does you want from your boss is I want my boss to care about me and I want him to let me grow.

Kaizen

We should want to care for people and help them grow. The results blew me away. Lean helped me to get people to grow. That’s part of what lean is, developing the people to do the work. When we were doing the Kaizen and we had many challenges to overcome. We had our staff making the improvements.

The image below was the Orange Bay two-stage. The bay was to make the unpredictable work predictable. One vehicle went through every 10 minutes. However, the problem with this is they had to take wheels off. Taking wheels off at a height, putting them on the ground, working on the brake system and then lifting it up would’ve been too much stress on the body. So, I said to the team, I need you to create plan and work out how are we going to do this. We needed something that was going to cradle that tyre.

INSERT BAG IMAGE io

The team of technicians got together with the workshop manager and designed the tool. And no, it’s not beautiful. But there’s a reason it’s not beautiful. I told them don’t paint things because we news paint things when you think they finished, leave it that way and use it and see where you need to fix it. Thus, it allowed us to put the vehicles through.

It was only when we had that tool, we could even attempt to do that kind of work where we were putting vehicles through every 10 minutes. This was because it allowed the technician to take the tyre off, put it down on the stand and then lift it up put it back on. It was a simple tool designed by the people doing the work.

On our receiving we had to receive batches of vehicles because that’s the way government worked. In the mornings the vehicles will be batched and sent to us. It took 20 minutes to do a vehicle for a service advisor. The service advisor would put the vehicle into single lane flow, and we were getting a 4-minute takt time. So, every 4 minutes a vehicle came out done, allowing us to stream them into the workshop to start being worked on. This activity was done by the staff doing the work. We set it up and we started the flows.

The Virtuous Circle

We did have some problems, but I spoke of Dave and Terry, and they gave some recommendations, but basically it was the team themselves that did it. It made a big difference once again to their self-esteem. They’d be working together on the activity; they understood the problem and they were part of the solution. They also understood it from beginning to end.

A lot of these staff although literate, didn’t have high comprehension levels. In Botswana they do get an education however the translation from Setswana into English is hard mentally comprehending the gap. So, this was quite a feat for them. But they became so joyful about doing all these changes and the difference it made to them in their lives, they just got stuck in and did it.

So, by this time the virtuous circle of continuous improvement to become part of our lives. Terry calls it the virtuous circle, once it starts it can only be good. If you look at our journey it was just a process. If you’re a massive business or your small business, you still must run through these processes. The one thing that we did do well was we were very unafraid of failing. I’m not saying we just charge into experiment. But we tried experimenting together.

We learned together, we failed together, we picked ourselves up when we failed, we brushed ourselves off and he said we will try again. This was one of the reasons we managed to do so much kaizen work because we were happy to fail, get up, brush ourselves off and not beat ourselves up. We just got on with it and made the changes.

I want to give you value. The only value that I can give you comes from my own experience. I offer you the keys of the four doors as transformation. if we I hadn’t have opened these doors, we would have failed spectacularly.

The door of alignment

If the value statement at the top of our house is not authentic, it is impossible to gain alignment. If we do not gain alignment, it’s difficult to build a culture. Alignment happens when people understand the value statement and proactively seek its usage when problem solving. When they do this, they feel supported by the leadership when providing this value to the customer. The key to the door is authentic statement that the leadership support and believe in consistently. It must be a 24/7 commitment like a lighthouse on a dangerous sea.

When we waver in this area, we cause confusion that spreads quickly everywhere. We have to believe if we want them to believe. We have to be consistent in our purpose, in our alignment. But we cannot align to something that is not true or real. We had mobility at the top of our house. So, every time people came to me with a problem, I asked them are you giving the customer mobility.

Because often the problem was about themselves and their issue. Then they would look again and they would say no or yes, but mostly it would be no. Thus, they would have to realign themselves and realign the problem to the top of the house. When they came back to me, then they could explain their problem better.

If you’re not true to what it says or if it’s created by a PR person rather than the people involved in the work of where they need to go, you can’t do an A3. The question is are we giving mobility? When you are looking at the answer it has to correspond. It has to go up it and answer that question.

The door of human resources.

We have to ask these questions:

- Has our HR department been part of the lean training?

- Do they understand their role?

- Do they understand their position?

- Are some of our organisations HR practices incompatible with the development of problem solvers?

- How are new staff members introduced to lean? Especially senior management level who have come from other companies that are not lean.

- Do they have mentors that are committed and strong enough to guide them?

- Do they know the boundaries they cannot cross?

The key is to build a close relationship with human resources where they know and support the changes. This might require additional training, it might require policy changes, it might require that one looks carefully at assessments and how they are carried out and ask the question how do we measure? Your understanding of this is important HR cannot be a distant planet. Like yourself, HR can make or break the trust of the team you need them by your side every step of the way.

The door of presence

Being present as a leader is vital. You need to be seen at the gemba, on front lines. It doesn’t mean just giving instructions, its mean having conversations, monitoring progress and engaging with the team. This presence will be about listening meeting the problems raised with empathy making sure that communication is productive asking questions not giving solutions respecting the people doing the work by meeting them where their where they are not where you are the door of reflection after working the gamba we need to make time to reflect on what we see it is vital to building our culture if the frontline is not reflecting the lean message you will know there’s a gap to close front lines are your hand mirror that’s why it’s called reflection if you are not seeing the customer value at this place for both the internal and the external customer you have found a gap all organisations have these doors the size of the organisation does not change this you have access to the keys within your sphere of influence and this is where you start you start with the people around you by developing them and helping them and so you will spread the message of lean Terry O’Donoghue in my first days of lean gave me a blank piece of paper and said right on it what you want to achieve it’s your story to write it was quite a scary moment for me because I’d been used to being an employee who was controlled by the two shareholders that worked in the business and all of a sudden I was given this scary blank sheet of paper so eventually I wrote a book so today I want to pass this gift on to you I give you a blank sheet of paper the storytellers are you the leaders you guide the power of the dragon and what it can accomplish.