Brief History of Modern Problem Solving Methods

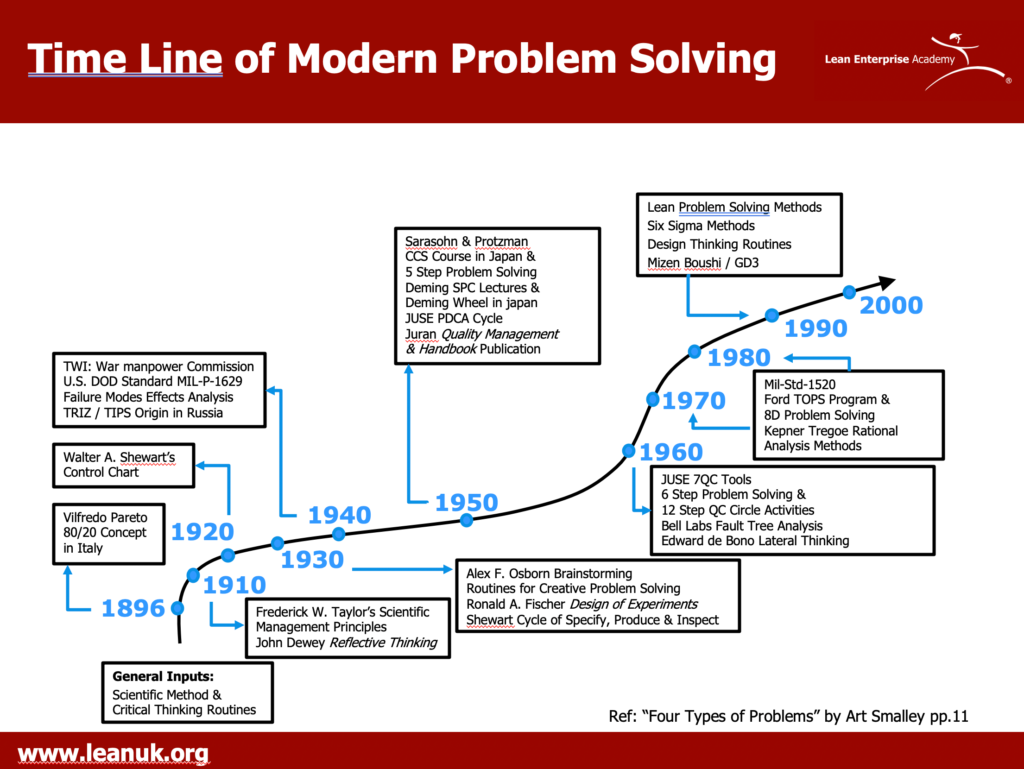

The diagram below shows a “Time Line of Modern Problem Solving” and depicts some of the key milestones that have led to the processes used for problem solving in organisations today.

It is possible to trace the strands of the modern problem solving approaches we are familiar with in the lean movement. A five step problem solving method was originally taught in Japan as part of a course called The Fundamentals of Industrial Management by Homer Sarasohn and Charles Protzman. Deming’s modified Shewart cycle – known as the Deming Wheel was taken and developed by the Union of Japanese Scientists and Engineers (JUSE.) JUSE was key in the dissemination of problem solving processes under the guidance of Ichiro and Kaoru Ishikawa. In 1951

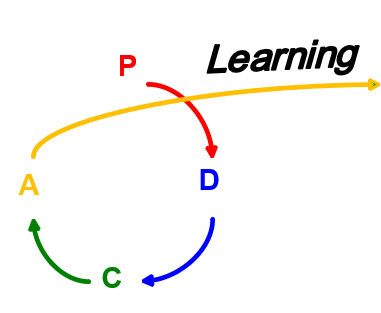

JUSE created the Plan-Do-Check-Act cycle which we know as PDCA. Despite Deming’s objections to the modification, this has become the dominant form of the Deming cycle today. They also invited Juran to Japan to give lectures in 1954.

Another key strand are the Training Within Industry (TWI) courses. Initially the 3J courses were taught, but in 1955, TWI Problem Solving was developed. The process outlined four basic steps of problem solving in the TWI framework to help train people, improve work methods and resolve problems in a structured way:

- 1 – Isolate the problem

- 2 – Prepare for solution

- 3 – Correct the problem

- 4 – Check and evaluate the results

In the 1960’s, various 6-step approaches were created. These can be summarised as follows:

Six Step Method

- 1- Define the problem.

- 2 – Determine the goal.

- 3 – Identify the root cause.

- 4 – Implement countermeasures.

- 5 – Check results.

- 6 – Follow up and standardise.

In the 1960’s and 70’s the concept of “kaizen” emerged in Japan. Its literal translation means “change for the better.” Different from structured problem solving and gap from standard situations, kaizen asks “How can the current standard or condition be improved upon?” Kaizen is not bound by the rules of root cause analysis thinking – it is more open ended. Processes are observed and considered for improvement.