Rooted in Purpose, Process and respect for People, lean is about creating the most value for the customer while minimising waste – resources, time, energy and effort.

Purpose, Process, People

We recommend that managers and executives embarking on the journey, answer fundamental questions (rather than copying solutions from elsewhere.) These can be organised around the issues of purpose, process and people:

- Purpose: What customer problems will the enterprise solve to achieve its own purpose of prospering?

- Process: How will the organisation assess each major value stream. Each step needs to be valuable, capable, available, adequate and flexible. All steps linked by flow, pull, and levelling?

- People: How can the organization ensure that every important process has someone responsible for continually evaluating that value stream in terms of business purpose and lean process? How can everyone touching the value stream be actively engaged in operating it correctly and continually improving it?

Where does Lean originate from?

The term “lean” was first coined by International Motor Programme (IMVP) researcher John Krafcik. It came to prominence in the best selling book “The Machine That Changed The World” co-written by Jim Womack, our chairman Dan Jones and Dan Roos in 1990.

A business book classic, “Machine” is recommended reading for anyone wanting to learn ‘what is lean’.

Using the term “lean production” led to early adopters focussing on applying tools and techniques to manufacturing. Whilst the final manufacturing steps are important, they represent only about 15% of the human effort in making a car. Therefore:

“To properly understand lean production, we must look at every step in the process, beginning with the product design and engineering, then going far beyond the factory to the customer who relies on the automobile for daily living. In addition it is critical to understand the mechanism of coordination necessary to bring all these steps into harmony and on a global scale, a mechanism we call the lean enterprise.”

The Machine That Changed The World (1990) pp.73.

The launch of “The Machine That Changed The World” in (1990) resulted in an ongoing process of action based research. The purpose being to learn more deeply about the subject, codify the principles and develop experiments to spread its use across the economy and society.

Lean Thinking

In 1996 we codified 5 Lean Principles in the landmark book “Lean Thinking.”

- Precisely specify value by specific product.

- Identify the value stream for each product.

- Make value flow without interruptions.

- Let the customer pull value for the producer.

- Pursue perfection.

What are the benefits?

Today lean has become a new, more effective approach to doing and organising work. It is a superior business system. Lean thinking and practice helps organisations become both innovative and competitive. This, in turn, allows them to become more sustainable. In such an organisation problems are opportunities for meaningful learning rather than errors to be swept under the carpet.

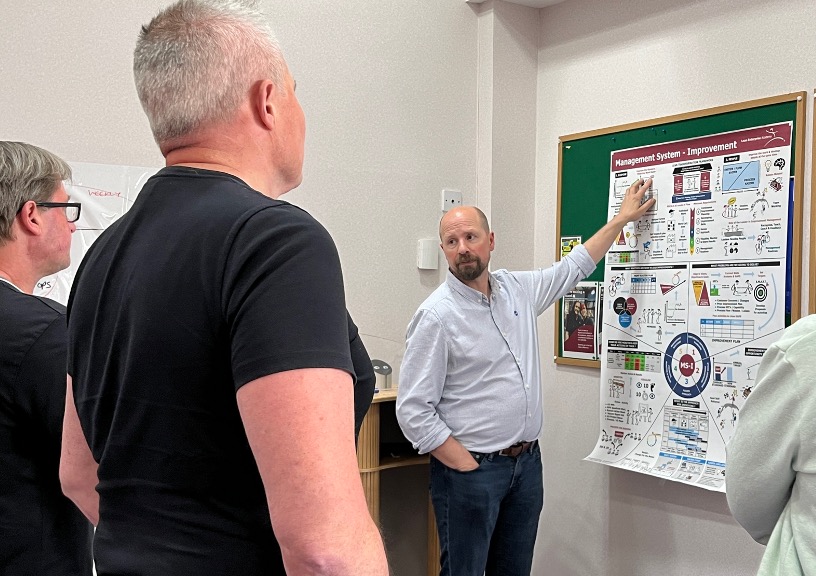

Managers act as coaches, helping others get comfortable identifying problems and practicing daily continuous improvement. Leadership means creating a management system to support a new kind of engagement with the real work at hand in order to understand the way the work is being done now, not the way you and your team hope to be doing work sometime in the future.

In 1997 James P. Womack established the Lean Enterprise Institute (LEI) in the United States. In 2003 Daniel T. Jones established the Lean Enterprise Academy in the UK. There is now a Lean Global Network around the world with the mission to:

- Improve the competitiveness and raise living standards of their country.

- Enable growth while minimising resource use and environmental impact.

- Provide more fulfilling work and continuing personal development for everyone.

- Enabling consumers to create more value in their increasingly busy lives.

There is an enormous demand for greater knowledge about lean thinking. It has spread across the globe and beyond other automotive manufacturers to sectors such as construction, healthcare, FMCG, the public sector, services and supply chain.

During our time researching and apply lean thinking and practice we have realised that learning it is a journey. Read Dan Jones’ article What Lean Really Is to understand this further.

Our Approach to Applying Lean Thinking & Practice:

The Lean Transformation Framework (LTF)

The LTF shows you how you can align organisational purpose to create more value for customers, whilst developing people at the same time

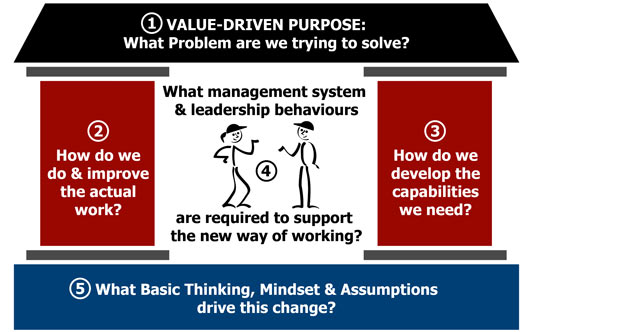

Use the (LTF) to develop the best lean journey for your situation. Based around five questions, it starts by asking “What problem are we trying to solve?” The LTF helps understand your gaps in applying lean to your situation, ensures you avoid common failures and helps you progress your lean journey

The Evolution of Lean

Back in 2014, Dan Jones wrote a great article describing the evolution of understanding of lean and Toyota’s management methods. Click the title below to read the article.

How We Support Your Lean Learning Journey

We have products and services that we offer to our customers based around 3 key value streams; Learn, Teach & Coach and Share. At the intersection of each of these processes is our Lean Learning Platform where we are writing down, in a usable form the key knowledge required to learn and implement lean.

The materials on the platform are organised around the Lean Transformation Framework which we both research and develop with partner organisations. These materials will help develop your capability and enable you to eventually become self reliant on your lean journey.

Does your organisation need support in applying lean thinking and practice to your unique situation? Our Senior Lean Coaches have a combined total of over 70 years Lean experience and have worked with hundreds of companies across the globe. Contact us below to learn more.