Process – Standardised Work

Watch the video to find out about the process conditions and considerations for a Standardised Work to be implemented successfully.

Process – Standardised Work Video

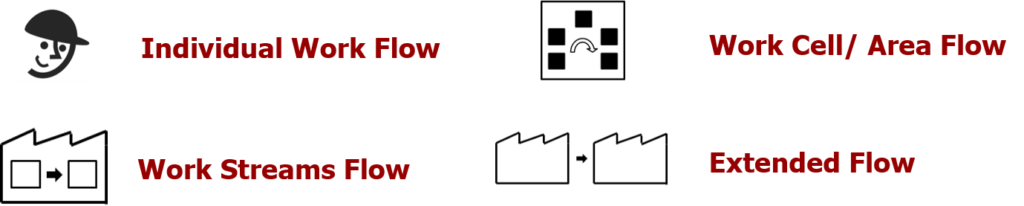

Process Levels of Flow

Standardised work can be applied at all levels of process flow.

Work at all Levels

From individual activities, work cell or areas, value streams through to extended flow between offices and/or factories.

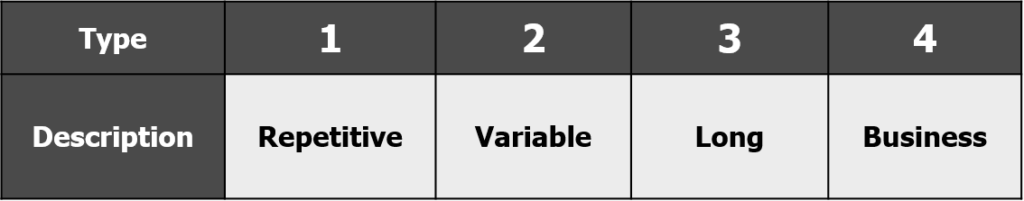

Standardised Work Types

Broadly speaking, there are 4 main types of standardised work used for different situations.

4 Types of Standardised Work

Type 1:

This is used for repetitive, production type work where the work content is the same/very similar from cycle to cycle.

Type 2:

This is similar to Type 1, but is used when the work can vary from cycle to cycle. The classic example of this is on a vehicle assembly line making sedan, liftback and wagon vehicles.

Type 3:

This is for long cycles of work content, for example the delivery of materials by logistics or a tool changeover. It is repeated, but not so frequently.

Type 4:

Typically, this is used for office or business type processes and activities.

The reason why we have different types is because we use slightly different approaches and documents when implementing it.

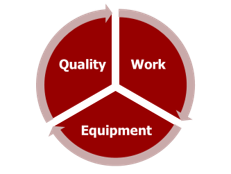

Required Process Conditions

Before implementing standardised work, there are some pre-conditions that need to be achieved.

Pre-Conditions

Work must be repeatable.

Equipment must be reliable.

Quality from the process must be capable.

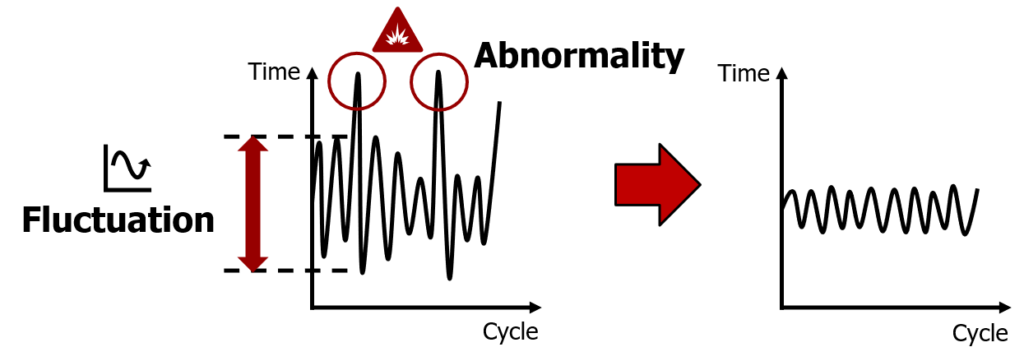

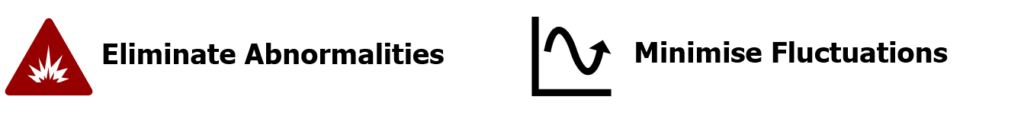

Process Stability

In-addition, the process must be stable. Eliminate abnormalities, minimise fluctuations.

If these process conditions are not achieved, the work activities will continually be interrupted/disrupted and it will be impossible to implement standardised work.

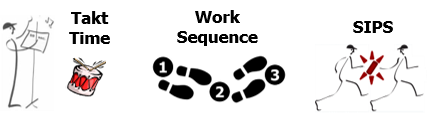

3 Key Elements

There are three key elements that are required to make standardised work.

Takt Time: The rate at which we must complete the work to meet customer demand.

Work Sequence: The steps required to complete the work.

SIPS (Standard In Process Stock): The minimum amount of stock required in order to fulfil the Takt Time and the Work Sequence.

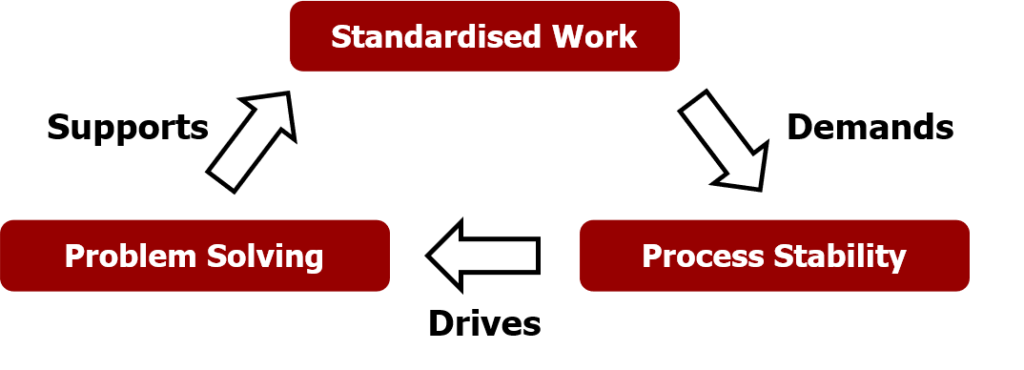

Summary

Implementing Standardised Work demands process stability, which drives problem solving, which supports the Standardised Work.

By doing this, we improve the capabilities of our people, who improve the processes, which improves the performance.