Background – Standardised Work

Standardised Processes & Procedures

“Without standards, there can be no improvement”

Taiichi Ohno – Father of the Toyota Production System

Standardised processes and procedures can take many forms/types:

- Safety, quality and environmental standards

- Standard specifications

- Work standards

- Standardised work

- Operator instructions

Without having established a standard or a baseline however, you can’t begin to measure any improvement.

Standardisation is therefore seen as the 1st Step of Improvement.

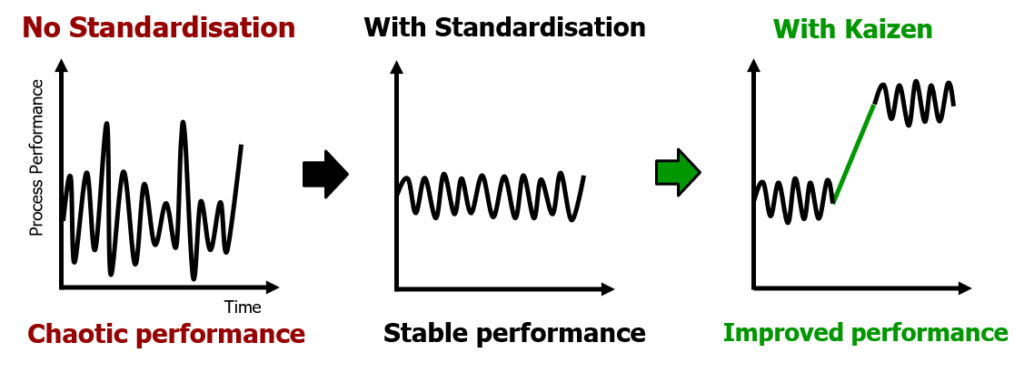

Process Stability

Establishing standardised processes & procedures is fundamental to creating consistent performance.

When the process is stable you can then begin a journey of continuous improvement – or kaizen.

To achieve process stability and improve you will need to become proficient problem solvers.

Everyday Examples

Standardised processes and procedures are used in many different industries to deliver consistently, good products/services to their customers, on time, every time.

Think about your experience when using these services.

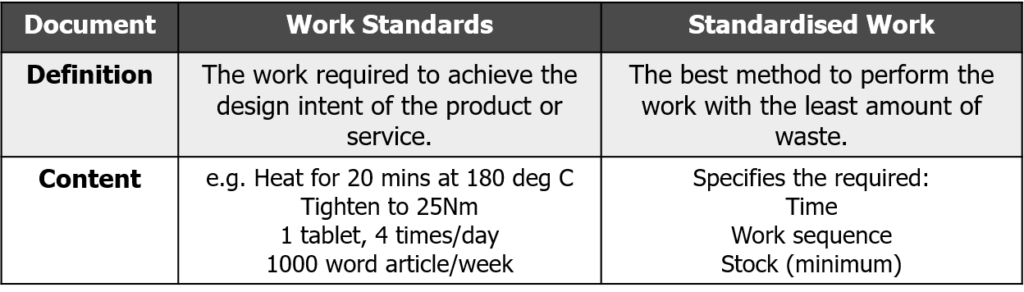

Work Standards and Standardised Work

People often confuse work standards for standardised work.

Both are required but they have different meanings and content.

Work Standard changes typically require changes to the design and/or specification of the product or service.

These are usually managed through some formal change process.

Standardised Work however does not impact the design and/or specification of the product or service.

Improvements or kaizen can be implemented quickly therefore, to enable a better, faster and cheaper performance.

Work Standards are required however, before defining the Standardised Work.

But they are not the same thing.