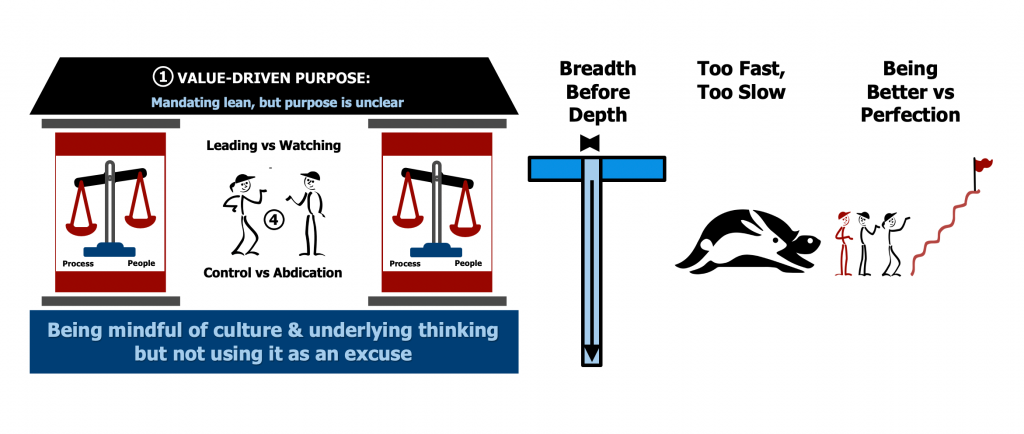

It doesn’t matter where you are on your lean journey. If you are not conscious of the potential failure modes when applying Lean Thinking and Practice you will struggle to avoid them. All of us can improve what we do. At the Lean Enterprise Academy part of our role is to study the efforts people make to introduce lean to their organisation, or their team or themselves. Here, we are using the Lean Transformation Framework as an aid to see the failure modes in lean transformation. There are lots of potential failure modes, but here are seven mistakes with lean transformations that we see most frequently.

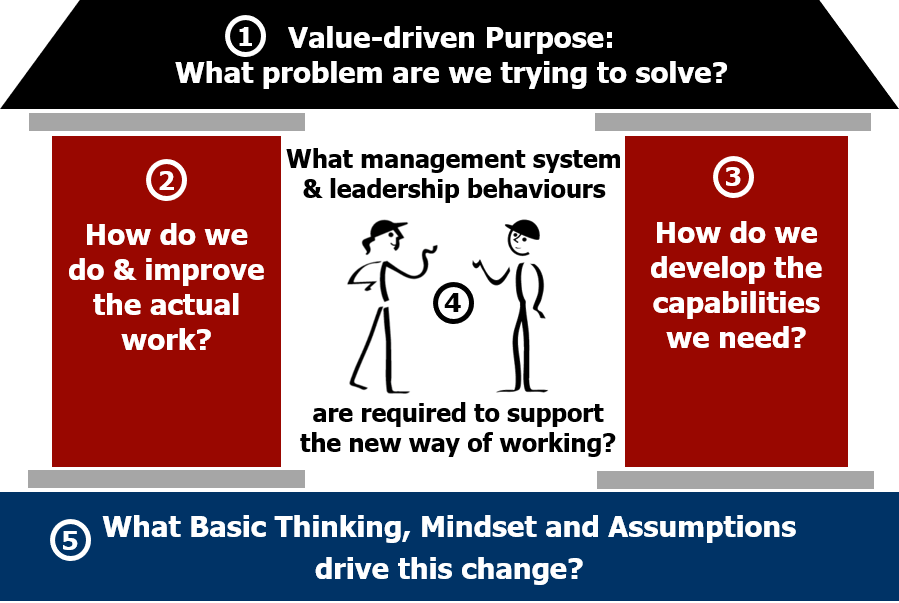

The lean transformation framework, first shared by John Shook in 2014, is a set of questions that anyone can use to see how their application of lean thinking and practice is going. The questions are organised around a “house” in which 5 dimensions (and questions) are explored. The point is not to become a level X at applying lean or to gain certification for its (or your) own sake. Instead, asking the questions exposes gaps to close. Recognising that, wherever you are on your journey, it is just that – a journey of learning and improvement.

1. Mandating lean, but purpose is unclear.

The first mistake is saying we need to do lean, but not being clear on the purpose for doing so. There are numerous examples of this. An automotive company we worked with several years ago had a lean function. It was mainly staffed by former Toyota executives who were earnestly trying to close the performance gap between their new and former employer. The former Toyota executives and their colleagues knew exactly why they needed to apply lean thinking and practice. However, their managers had difficulty articulating why, beyond the argument that they needed to catch up with Toyota. We have seen similar examples in supply chains in sectors as diverse as construction, healthcare and FMCG. “We are doing this because our customer has asked us to.” “It was part of our consultants’ recommendations” and so on. Why are you doing lean? What is the purpose?

By now you would think this kind of thing happened less frequently. But the fractal nature of lean thinking often shows this failure mode is alive and well. We have observed several organisations develop excellent strategies based on lean thinking only for functional heads and senior managers to not engage with the strategy. Why? Is the messaging clear enough? Is the strategy compelling enough? What will each actor in the system lose or gain?

2. Focussing on the technical and ignoring the social or focussing on the social and ignoring the technical.

Any organisation has both social and technical systems at play. The organisation or individual that ignores the need for these to be in balance does so at their peril. A look at the literature (and more recently internet posts) on lean reveals that the 1990’s and early 2000’s emphasised the technical side of lean. The tools and techniques. The community then emphasised the leadership elements and what is often termed the “soft” side of change. Developing stability requires a balance between the technical and the social aspects. What is the work to be done? How will you do that work? What capability do you need and how will you develop those capabilities?

3. Going broad before going deep.

Almost all the early lean examples had one thing in common. They employed a concept called the “model line.” The idea behind the model line is simple. It’s about creating an example. Showing how good performance can be whilst at the same time developing internal capability to develop and operate in a new way in a defined space. For those involved in a model line implementation the benefits are obvious. You don’t give a novice pianist Liszt’s “La Campanella” (little bell) when they start learning and have only just mastered “Three Blind Mice.” Confidence grows by building on improvements with short feedback loops.

I have yet to see a sustainable example that didn’t start with a deep pilot model line. However, knowing when and how to spread the lessons learned is also key whilst avoiding the mistakes of copying which come from a “we need to roll this out” or “we haven’t got time, we need this everywhere” mindset. Such thinking leads to much rework and much longer lead times overall.

4. Going too fast or going too slow.

Going broad before going deep is linked to the failure mode of going too fast or going too slow. Trying to go too fast outstrips the organisation’s ability to develop capability. However when we go too slow we lose the sense of urgency and the excitement needed to sustain the gains. How fast can you go? One useful countermeasure to the issue of speed is to break the plan (that presumes you have a plan) into bite sized pieces and increments of time. What can you do in 30 days, in 60 days, in 90 days and so on? How will you tell if you are behind or ahead?

5. Management’s role – Leading vs Watching, Control vs Abdication

The simple view is that the success (or failure) of lean rests with management. To an extent that’s true, but there are many dimensions to observe and understand for a given situation. Do you assess the strategy and then determine the structure or change the structure and then assess the strategy? What is your current management system and how is it characterised? What do management spend their time on? You want them to spend more time on improvement, but do they have an effective system for managing performance? Do you have processes in place to develop capability to manage teams effectively? Is there a process for moving through the organisation? How are individuals reacting to external factors affecting the organisation? As with any problem solving, grasping the current situation is the first step.

6. Being better vs achieving perfection?

Underlying thinking is difficult to see. But what people say vs what they do can be seen quite easily. The fifth principle in lean thinking is about striving for perfection. The more waste we remove, the more we see. However there is a balance to be struck between trying to be perfect vs settling for better. There is a contradiction here. We want people to improve, we are striving for perfection. But we don’t want people to wait or stop because they can’t reach perfection. We typically see perfection stopping better where a new computer system, a new machine, a new site or a new product is in the pipeline for launch. The underlying thinking that it will be much better when we have done X. That may be true, but not doing anything until then is dangerous. It can limit engagement, reinforce big leap thinking and reduce ownership.

7. The impact of “culture.”

Every organisation has a culture. For a recap on what culture is, see this excellent post from John Shook published in MIT Sloan Management Review. https://www.lean.org/downloads/35.pdf John says, “What my NUMMI experience taught me that was so powerful was that the way to change culture is not to first change how people think, but instead to start by changing how people behave — what they do. Those of us trying to change our organizations’ culture need to define the things we want to do, the ways we want to behave and want each other to behave, to provide training and then to do what is necessary to reinforce those behaviors. The culture will change as a result.” Anyone wanting to change a culture needs to define the actions and behaviours they desire, then design the work processes that are necessary to reinforce those behaviours.

Before we design countermeasures, the starting point is to understand what the current situation is. In this case what the culture is. We need to be mindful of our culture without being overly cautious of it. We shouldn’t let our culture become an excuse for not moving forward.

The Lean Transformation Framework

Balancing the 5 dimensions of the Lean Transformation Framework helps avoid these 7 failure modes. Lean thinking has a point of view on each of the 5 dimensions. Over the years we have seen many attempts to evaluate the progress of “implementing lean.” Most attempts fall short. Either as a tick list of tools to implement, or as stages to reach. Do you have a process for evaluating your progress? Have you used these questions to try to conduct an evaluation? Have a go at using it. I am confident you will have insights from the process.

We are always on the look out for firms experimenting with the framework. You never know, we might even include you in a book one day! If you’d like to learn more about the Lean Transformation Framework, we are hosting a webinar on the 15th June at 3:30pm UK time. Tickets are available here and are only £24.99. Alternatively, you can purchase an on-demand version of the session, which gives you access to a recording and the digital materials used.