Rapid Problem Solving Questions and Answers

In our Rapid Problem Solving webinar from December last year, there were key questions from the webinar attendees which were addressed. We have complied the discussions into an article for you to read. We have also included some useful links to learning materials (including details on our upcoming problem solving webinars) which may be useful for you. Here are some of the key talking points:

Taking too Long to Solve Problems

I’ve been doing some reading on Art Smalley’s book (Four Types of Problems) because we’ve applied the 8 step methodology and we’ve invested a lot of time with our people and finding that the problems are just taking too long to solve. Could you just give and share some advice as to what gaps we might have in terms of our approach?

David Marriott:

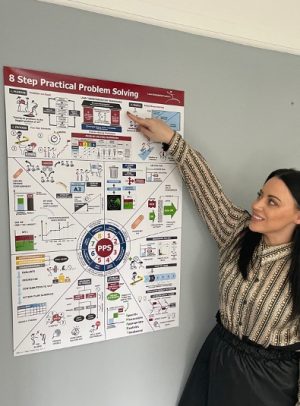

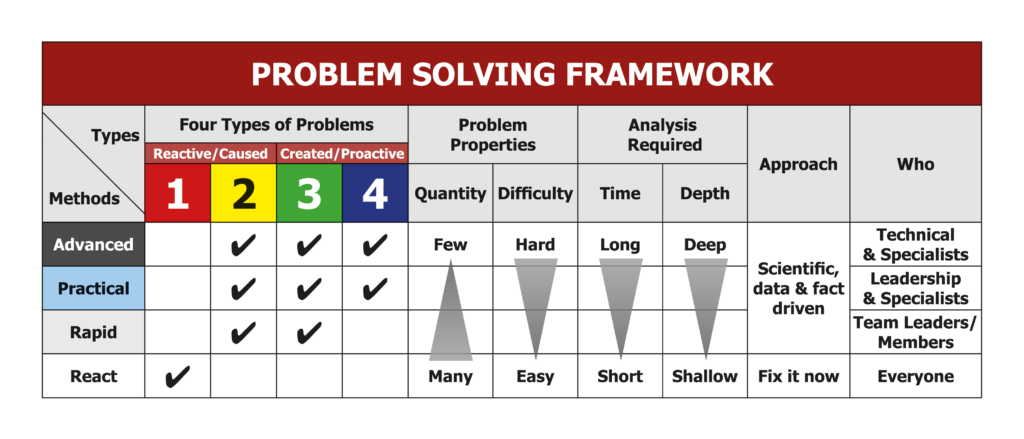

I think this comes back to the Problem-Solving framework we showed. The 8-step process does take time. Firstly, to understand the 8 steps then secondly to actually tackle the problem. I think the trade-off is really to think about where someone is in the business in terms of their seniority and what type of problems you are handing off to them. A3s are great but if all you’ve got is a hammer, everything looks like a nail. Try and be more selective about the types problems you’re handing off to people. These should be some bigger business level problems which probably take time to analyse and get to some conclusion, and the reason why we’ve got the four step method is because “we don’t need an A3 for everything but we do need the thinking way”.

Rapid Problem solving is really good for those “day to day” performance related issues and introduces people to tackle problems using a scientific method. Concern, Cause, Contain, Countermeasure… Then for the bigger business challenges you need to drop onto that to do an 8-step practical problem solving A3. My experience at Toyota is that if you have an A3 to do, it will take around 12 weeks to do to see it through to implementing the countermeasures and starting to track the results.

Developing the Right People in the Right Methods

For our team on the shop floor, they’re learning the 8-step methodology as their first tool to solve problems and are applying it at the day-to-day level. However there’s a disconnect because they need to build their own their own problem-solving skills. Now I see there is more of a need for rapid problem solving methodology at this level, hence why myself and all my team are on the webinar.

David Marriott:

When I was at Toyota we only introduced the 8 step process when you were either a group leader/senior group leader or specialist with some years of experience. Your team member, team leader level are not expected to use it because they don’t expect to see those challenging problems, but more on the day to day performance related issues. You’ll probably overwhelm them and that’s probably why it’s taken quite a long time and a lot of coaching support. It can knock a team member’s confidence as well if they don’t think they can progress.

David Brunt:

If a person’s confidence is knocked and it takes too long, there will be temptation to go back to what they did before. And what they did before was probably not Plan Do Check Act (PDCA), so not the thinking way to think about the concern, cause, and countermeasure. In a lot of cases people are not even using something as simple as 5 Whys. So, if you put all of those things together and then on top of that you ask them to fill in standardised forms etc., it’s a recipe for disaster.

Peter Watkins:

At that level, you need to really integrate it into their work and make it visual in their own work area to capture problems. And then manage the actions on those problems as well. It’s not just about capturing the problem and getting to root cause, they’ve got to manage the action as well. You need to integrate that into their work area and what they’re doing. Dave explains this in the webinar.

Leaders Teaching Problem Solving Skills

What is the biggest challenge you see with leaders learning problem solving & what level do they need to be at for effective coaching of Problem solving on the shop floor?

Peter Watkins:

We always recommend that at manager level people start off with the 8-step, because they’re going to be the ones tackling the larger more complex business problems. Also, once a manager is capable of 8 step, it’s then very easy for them to teach & coach the next level down on 4 step problem solving to build the capability of the organisation. It’s easier because they got the right thinking, and they understand it well as they’ve had to go through the full 8 step learning process.

When we go into organisations, we will start off with 8-step with the more senior leaders/the manager level. Then we’ll get them to teach Rapid PS to the next level down and give them skills. It’s important external coaches don’t ever go down to the next level because they would be taking away the ownership and responsibility from the leaders to build the right culture. They’ve really got to do that themselves with the next level down and show / lead it.

David Brunt:

You need to do a few problem solving activities before you launch into teaching it. It’s the same old thing of “if you can’t do it yourself then don’t try and teach it”. The other thing is to make sure that you’ve been through the process a couple of times and you’re comfortable with the process. Then you can start that process of teaching it to others. But like Peter said teach the 4 step process. And make sure the problems are really things that team members need to solve.

Rapid Problem Solving versus A3 Practical Problem Solving

In general, what percentage of problems can or should be solved using Rapid Problem Solving versus A3 Practical Problem Solving?

David Brunt:

I think it’s very difficult to give you a number, it depends on the situation really. In any process there’s 10s of problems every single day, relating to customer requirements, products and processes. Just think man/woman, method, machines, materials. A large proportion of those can be solved with the practical problem solving versus maybe some of the managers each having one or two A3s on the go. The lead time is a function of the work in progress, so the lead time to solve problems is a function of how many problems you’ve got on the go at any one time and how long each takes to solve. You’ve only got a certain amount of time to solve the problems and do the work, so don’t end up with having loads and loads of work in progress of part finished problems.

Embedding Rapid Problem Solving into the Culture

How long does it take for you to get fully familiar with the RPS steps? They’re great tools for us to have, but if I’m down on the line doing the work…How long did it take you before it became second nature? or does it never?

David Brunt:

It’s like learning a language. If you don’t keep practicing it, you soon fall into bad habits and go back to jumping to solutions. I think that’s really our natural tendency, is the jump to solutions. For example, if we were going through the bush in Africa and we saw a big lion close by you wouldn’t get a flip chart out or a whiteboard and start thinking about concern, contain etc. we’d just hope could get away from the lion, or that the lion left asap.

It’s a practice thing and you’ve got to put the effort in to do the practice. The fuel tank example (as spoken about in the webinar) which the Toyota dealer worked through was carried out over 2-3 weeks. When you think about that as a problem, what would you rather do? There were 42 rework jobs. If you don’t solve the problem you continue spending time on rework. Solve the problem and you have more time to solve problems. The fact that they were able to go through that process and then say potentially they have lots of other jobs that become rework because they don’t really follow a good process, means that solving this issue and spreading the thinking to other work gives greater benefit than anyone thought would happen initially!

Peter Watkins:

Building in KPI trigger points which are visually shown on daily performance review boards really helps integrate problem solving into the daily work quickly. If you’ve got clearly visual KPIs and you’ve got a gap (Planned vs Actual and GAP figures shown simply), then the expectation is there is a problem-solving activity to close the gap and it connects the two. Whereas a lot of people have boards with performance KPIs and they’re not connecting the problem solving into it to close the gaps.

This helps makes RPS a daily habit then, because we’ve got a gap on the KPI, so what are we doing about it? And then managing to closure in your performance review.

A lot of people start trying to solve the problem in their daily performance review which is wrong. You should be doing problem solving during the day in real time and then use a daily review to manage the action / countermeasure status to closure. Understanding if it had a good effect. People mix all those things up and don’t learn it well. If you’ve got the rigour of a good performance system, then that helps as well.

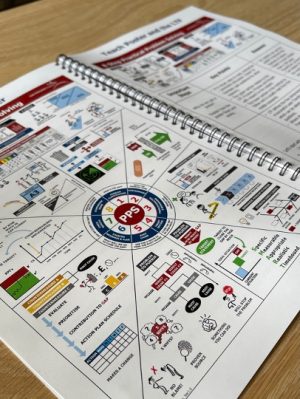

The guy that did the RPS in our example was the technician team leader. The reason why I went through the quadrant chart was to embed the learning, so it became second nature to go through that process. As we’ve said he’s not conducting quadrant charts and filling loads of forms for every problem, but initially to get him into the thinking way, it was necessary. And he’s now translated that to the board, as Dave shows (in the webinar). There are some problems which would be useful to share with others, then it’s worth documenting and going through the RPS process.

David Brunt:

To answer the question a bit more directly around 3 to 4 weeks, depending on whether you end up with something that’s successful first time. It’s important to choose the right thing when you start as well and there’s a skill to that. Don’t choose something that is really hard as a first go because, if it’s massive and it’s been happening for a long time, it might be difficult to solve. So, you choose something that you’ve got a good idea that it will be solvable, because that then gives everybody confidence.

How do you develop capability for Rapid Problem Solving

If we were to deploy this approach what would be next steps into an organisation?

Peter Watkins:

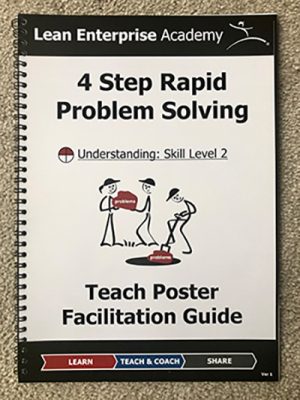

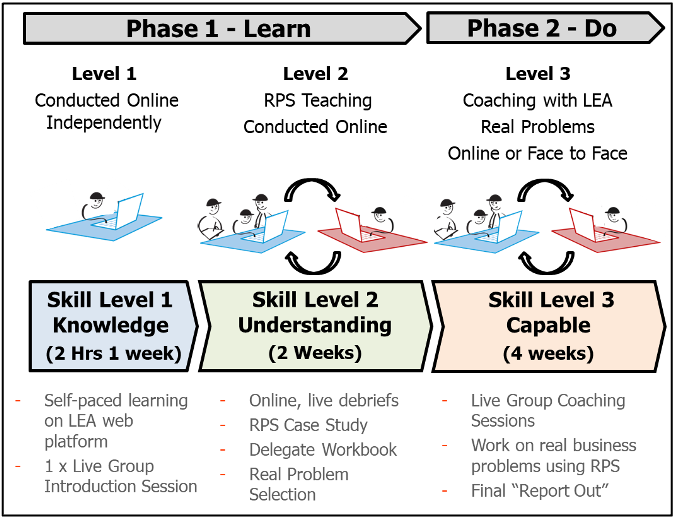

We recommended you go through the 4 different skill levels using our learning process for RPS. But first spend time to select the right leaders or managers to develop. They will become the organisational teachers & coaches of RPS. The starting point is the basic knowledge around the Purpose Process & People of RPS – Skill Level 1. Don’t waste your time physically training everybody in this, they can just go onto our online course and do that.

Next you will need to select someone (or bring in someone) in your organisation that is already capable to teach and coach others in RPS to Skill Level 4. They can then take the learning managers through and check their thinking on our skill level 2 course. This is done by going through the RPS case study that we developed. Using our case study is a safe way for them practice RPS and get feedback to adjust their thinking.

Then the coach can take the learners through the Skill Level 3 (Capable) learning process, so they can solve some real life business problem and receive on going feedback as they do this.

Following those Skill Levels and stages is what we recommend in terms of how to start. But we also suggest that you don’t do all your leaders in one go, instead pilot in one area or one team first and run through that. A sort of inch wide mile deep thinking when you’re deploying it into an organisation. Then check act on what are the issues you’re having with the purpose and people elements.

David Brunt:

What you’re ideally wanting to do is “teaching people to fish”. You want a small group that you choose as a pilot, and you want to teach them so that they can teach other people, because internally, inside your organisation is what you do yourself that ultimately sticks. Rather than blanket training for everybody, you need to make sure that you’ve got enough support for those initial groups to be successful. If not, you can’t support enough of those people, and thwhat you’re ideally wanting to do is “teach people to fish”.

You want a small group that you choose as a pilot, and you want to teach them so that they can teach other people, because internally, inside your organisation it is what you do yourself that ultimately sticks. Rather than blanket training for everybody, you need to make sure that you’ve got enough support for those initial groups to be successful. If not, you can’t support enough of those people, and then people say, “well we tried this before this doesn’t work”. Be mindful of building the capability.

Peter Watkins:

We’re doing this with a partner organisation at the moment. We are working directly with the manager and the process leaders and we’re developing them first in rapid problem solving and they’re going through the first 3 stages there that we showed you (in the webinar). Then their expectation is to take their team members through that same process so they can develop them. We help them through that learning process.

Engaging all your organisation in Problem Solving

How would you best “sell the approach” to Team Members to more readily embed the thinking in an organisation?

David Brunt:

I think people quite often use the idea of people buying into something. I much prefer to think about how you’re going to engage people in a better way of thinking about things. The best way to do that is have them think about it. Rather than push stuff onto them, you need to find a way so that you encourage them to pull – make the problems with the work visible!

Peter Watkins:

A good example is what we have also done with another partner company, that we’re currently developing the leaders in RPS.

Rather than starting with problem solving, the first thing the leaders did with the team members is teach them what we call “Lean Fundamentals”. So, starting with the team members, Lean Fundamentals takes them through the basics about what is waste? They do that through “learning by doing” process observation. It also goes through and helps them understand what’s nonvalue added work vs value added work? and why lead time is so important etc.

Lean Fundamentals is just the very basics and it’s very quick, but by doing this they will observe their own process and they’ll come up with lots of problems with the work. When we did that with the partner company, they came up around 20/30 problems, just within 10 minutes of observation. This engaged Team Members in solving some of their problems and recognising that it will make the work easier. You have to go through this alignment with team members to engage and bring realisation that those things are actually problems with the work.

David Marriott:

The RB 3 fuel pump example (explained during the session) causes the worker real pain as they were responsible for that area and were getting all this rework. Once we went through the process with them to solve the problem, they were onboard.

Peter Watkins:

The reason for doing lean fundamentals with team members is to make the work easier. People can relate solving problems to make the work easier. Everyone wants to do their bit and go home and not have the boss on the back! If you can relate to making the work easier a lot of people get really engaged quickly.,

You’ve got to get Team Members to see the waste though, a lot of people just don’t see it at first. You have to go through that observation and get into deeply thinking about the process. Especially in office areas people tend to put up with even more waste than in a manufacturing environment, you know it’s just always been that way! – Engaging with people to recognise problems with the work through seeing the waste or understanding the pain caused is the first step.

Upcoming Webinars on Problem Solving

Rapid Problem Solving Webinar

The Lean Enterprise Academy is hosting its Rapid Problem Solving webinar this month on the 23rd March at 3:30pm GMT. If you’d like to learn more about the session click here.

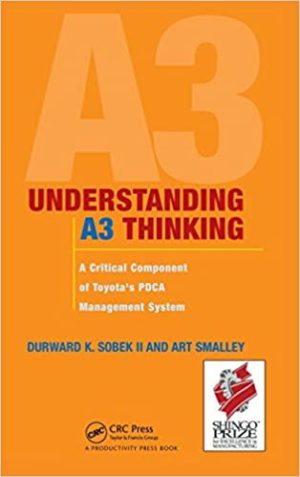

A3 Problem Solving Webinar

The Lean Enterprise Academy is hosting its A3 Problem Solving webinar next month on the 23rd March at 3:30pm GMT. If you’d like to learn more about the session click here.