It is fair to say that over the last quarter of a century the term lean has spread to almost every sector. In the early days of implementation the manufacturing companies visiting Japan to see what Toyota was doing had a number of false starts or lessons learned (depending on whether your glass is half empty or half full!) Early implementations focussed on empowered teams and continuous improvement (kaizen) or attempts to replicate a pre-defined box of tools such as 5S, SMED, SPC and kanban. For others lean principles became synonymous with kaizen events – that were actually kaikaku – radically reconfiguring individual operations. For some, this led to them developing their version of Toyota’s famed Production System (TPS) including their own schematic “house” or “temple” of lean transformation along with departments of continuous improvement specialists.

In each new environment that lean has entered – such as the service environment (including banking and insurance), healthcare, construction, public sector or retail we’ve seen examples of implementations that have followed a similar path. When I attended the 2013 Lean IT Summit in Paris I was expecting a similar situation, however I was surprised and encouraged by what I heard.

What we now know is that applying lean principles is situational – it depends upon the circumstances we are operating in and the business problem(s) – the gap(s) to close. The agile movement was already prevalent in the IT sector and some folks were trying to adopt lean IT methods inside this approach. However, what really interested me were three further strands that have emerged. Firstly, the Lean Start Up movement was very much in evidence drawing on the excellent book by Eric Ries which in many ways gets to the heart of what lean is all about – solving problems for customers. Secondly the work that Toyota is doing to translate lean principles and use the Toyota Way in IT. Thirdly the work that is being done by a number of companies to embed lean principles into project management – using visual management, oobeya and PDCA. This last area is applicable beyond the IT arena.

Encouraged by this event we asked Pierre Masai to speak at our own UK Lean Summit in 2013. You can see Pierre’s talk on our YouTube Channel and you can catch up with Pierre at this year’s Lean IT Summit in Paris. The full programme can be found here It promises to be a fantastic event.

However if you can’t get across the Channel to France (or if IT is only one of your interests) we’ve invited Sandrine Olivencia to conduct a learning session titled: “Managing successful projects using oobeya and visual management.” The lessons learned in the Lean IT area are applicable beyond this sector – to anyone managing projects. Sandrine’s workshop practically examines what is required to do this.

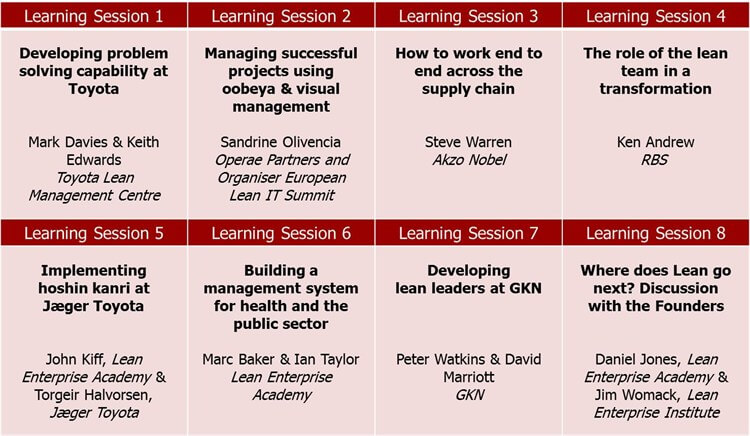

A full list of learning sessions is outlined below:

The Summit provides:

- Learning on the latest developments in Lean Thinking and Lean Practice.

- Practical ways to get started, deepen or enhance your lean journey.

- A great event to meet others and build your network of Lean Thinkers.

This is a unique opportunity to learn from the best lean practitioners and sensei. In conjunction with six plenary talks the content of this year’s Summit is better than ever.