Lean Transformation: Practical Next Steps

20% discount when registering 5 or more delegates

As part of our mission to help organisations with their Lean journeys the Lean Enterprise Academy is holding its annual UK Lean Summit at Chesford Grange Hotel, Kenilworth.

Our first UK Lean Summit was held in 1997 and since that time we have held a Summit each time we have felt that there was something important for the Lean Community to hear.

- 6 Presentations

- 9 Learning Sessions

- 3 Lean Masterclasses

The purposes of the Summit are as follows:

- To raise consciousness of the latest developments in Lean Thinking and Practice

- To provide insight into practical ways to get started, deepen or enhance your Lean journey

- To enable participants to build their own network of Lean Thinkers

We do this by:

- Bringing together the best Lean practitioners and sensei in the Lean world for participants to learn from

- Building time into the programme for participants to network

- Providing pre-Summit workshops on leading edge topics

- Enabling groups from the same organisations to come to the Summit to learn together

Key questions for this year’s UK Lean Summit:

- What does it take to move beyond legacy assets and mind-sets to involve users in creating new lean solutions?

- How to build a management system to spread lean across the organisation?

- How to develop leaders to implement, sustain and expand lean transformation?

- How to develop problem solving capability in the organisation?

- What are the key elements of Lean transformation?

- What is the role of a lean team in a successful transformation?

- What are the key lessons learned from applying Lean Thinking in different sectors (Government, Health, Industry, Retail and Service) both internally and across the Supply Chain?

- Where does lean go next?

This is a unique opportunity for the Lean Enterprise Academy’s community to come together.

Scroll down for the full programe

Click the register here button to book online using your credit / debit card now

If you would like to receive an invoice to arrange a bank transfer against please complete and return this booking form to [email protected] or fax to +44 1600 890540

Delegate Information

Please supply the names, email and job title for each delegate, as well as any dietary requirements. Please telephone the office on 01600 890590 to discuss any other specific needs

Confirmation, Cancellations and Substitutions

Once registered, you will receive a confirmation by email.

Substitutions may be made at any time.

In the event of cancellation, the following cancellation charges apply:

- within three months – 20% of the Booking Charges

- within one month – 50% of the Booking Charges

- within two weeks – 90% of the Booking Charges

The Venue

Chesford Grange Hotel

Kenilworth

Warwickshire

CV8 2LD

UK

Tel: +44 (0) 1926 859331

Web: http://www.qhotels.co.uk/hotels/chesford-grange-near-warwick.aspx

The Chesford Grange Hotel is set in 17 acres of magnificent grounds near Kenilworth, right in the heart of historic England, close to Shakespeare’s birthplace in Stratford-upon-Avon.

It is a short 25 minute taxi ride from Birmingham Airport, or 1.5 hours by train from London.

An ideal place for a short break before or after the Summit.

The bedrooms are equipped with TV, telephone and Internet connection. For relaxation there is a well equipped health & fitness club.

Parking is available at the hotel free of charge for delegates.

Delegates attending the summit can view speakers’ presentations by entering the password provided at the Summit.

Please note these will only be available for 30 days.

- Simply brilliant, experiential learning at it’s best

- The only forum for real exposure and learning regarding Lean

- It’s powerful, interesting and the only Lean Summit I know of happening in Europe at this level

- Great conference probably the best I have attended due to the calibre of content and presentations.

Registration

Creating a Lean Transformation

Introduction

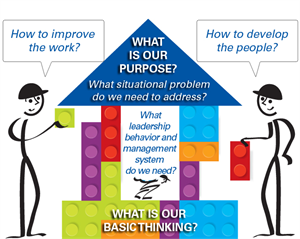

In January 2014, John Shook shared the Lean Transformation Model – the model the Lean Enterprise Institute, the Lean Enterprise Academy and members of our Lean Global Network have been developing to guide transformations with our partner companies, large and small, across a wide range of industries.

We explore each of the five areas of the model – facilitating discussion around the obstacles required to close gaps between each organisation’s current state and the proposed target condition.

Objectives

The purpose of this workshop is:

- To provide a framework for Lean Transformation

- To explore the five areas of the Lean Transformation Model

- To develop personal and team action plans

Topics that will be examined include:

- Developing organizational purpose

- Steps and activities organizations can take to improve the actual work

- Building organizational capability for lean

- Understanding the leadership behaviours required to lead and support lean transformation

- The basic thinking, mindset and assumptions comprising culture

- Failure Mode Effects Analysis of Lean transformation

Workshop Benefits

Through instruction, small group discussions, exercises and video workshop participants will:

- Learn about the key elements of a successful lean transformation

- Discuss and reflect on how to go beyond where they are now – to close the next set of gaps in the organization

Who Should Attend?

Leaders, management teams and lean teams wanting to examine their lean implementations

Dave Brunt - Chief Executive, LEA

Key Concepts of Lean

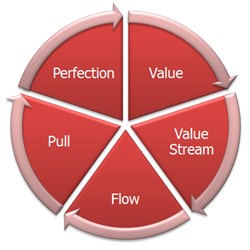

LEA has continually conducted experiments to develop ways of explaining the key concepts of lean with higher quality in a shorter lead-time. In this workshop we use a simulation to help any organisation understand the five lean principles – value, value stream, flow, pull and perfection whilst integrating the concepts of purpose, process, people and the scientific method of PDCA.

Objectives

The purpose of this workshop is:

- To provide a method to grasp the key concepts of lean in a effective and efficient way

- To show participants the key concepts of how to define and solve business problems at all levels using the PDCA model and to sustain the improvements

- To develop participants’ ability to practice or teach lean

Topics that will be examined include:

- Purpose, Process, People and the Lean Transformation Model

- Customer value – Contrasting Customer Satisfaction with Customer Fulfilment

- Value and Waste and the five lean principles

- The 8-Step / PDCA problem solving process including some of the key tools for:

- Clarifying and breaking down the problem,

- Grasping the situation including mapping and analyzing the causes

- Sustaining the gains and revealing other problems

Workshop Benefits

Through instruction, discussions, a video workshop and a simulation activity, participants will learn the importance of:

- Understanding and focusing on customer value at every step and seeing the link between customer purpose and business purpose

- Resolving problems in a structured way

- Using PDCA to sustain the improvements effectively

Who Should Attend?

Individuals with little to moderate experience of lean who are looking to increase their understanding. Managers who want an understanding of the total scope of implementing lean. Managers who want to improve their communication of lean.

John Kiff - Lean Coach, Lean Enterprise Academy Limited

Making Hospitals Work

Introduction

After over six years of working with many healthcare organizations, Ian Taylor and Marc Baker had learned what works and what does not work in healthcare (and why). In 2009 this was codified into their book ‘Making Hospitals work’

Five years on, and given the pressures now being experienced globally in healthcare, the messages contained in their book are now more relevant than ever.

These days Ian and Marc rarely have the time to present their ‘up to date’ findings in a workshop format. As a result this presents a scarce opportunity to attend this workshop.

Objectives

This workshop will help hospital management teams to answer the following questions:

- What are the biggest problems in your hospital?

- Do most of your patients go through similar diagnosis and treatment steps?

- How long does the end-to-end patient journey take – and how long could it take?

- What is the demand to get into your hospital – and how long do patients have to wait?

- How could you eliminate most of the waiting time within and between departments in your hospital?

- What is the demand to get out of your hospital – and how many patients are ready to go or are in the wrong beds?

- How could these activities be managed visually to track progress and to respond to problems and delays?

- Who will take responsibility for transforming the end-to-end patient journeys through your hospital?

Clinicians use the scientific method to diagnose and treat patients – which is the foundation of evidence based medicine. This workshop will show how we can use the same scientific method to diagnose to the root causes of broken healthcare systems and using evidence based management come up with the appropriate countermeasures to improve the patient experience, relieve the overburden on hospital staff and treat more patients while saving hospitals’ resources. It will show how to map the core end-to-end patient journeys and the critical support processes through your hospital and will go through our learning about how lean thinking has to be adapted to a healthcare environment.

Workshop Benefits

Through instruction, small group discussions and exercises, the workshop will show the participants how to:

- Funnel their organizations’ many problems down the to their single biggest problem

- Discover their current condition

- Set their target condition

- Establish the root causes of their biggest problems

- Think differently to enable them to come up with and implement their own, carefully planned, successful solutions to their organisations’ biggest problems

Who Should Attend?

We will all experience healthcare at some point in our lives and as a result this workshop will be relevant to people from any sector. You will certainly benefit from this workshop if you are a healthcare executive, physician, nurse, allied health professional, commissioner, or other healthcare provider who wants to move your organisation to become a safer, more effective and efficient provider of patient care..

Marc Baker - Lean Coach, Lean Enterprise Academy Limited

Ian Taylor - Lean Coach, Lean Enterprise Academy Limited

Registration

Welcome and Introduction

Dave Brunt - Chief Executive, Lean Enterprise Academy Limited

Beyond Legacy Assets and Mind-Sets: Involving Users in Creating New Lean Solutions

Daniel Jones - Chairman, Lean Enterprise Academy Limited

Spreading Lean across Health and Government: The Saskatchewan Experiment

Dan Florizone - Deputy Minister of Education (Former Deputy Minister of Health), Government of Saskatachewan

Coffee, Tea & Networking

Developing Problem Solving Capability

Mark Davies - Senior Manager, Toyota Motor Manufacturing (UK)

Keith Edwards - Section Manager, Toyota Motor Manufacturing (UK)

Lunch

Developing and Deploying Hoshin Kanri at Jæger Toyota

John Kiff - Lean Coach, Lean Enterprise Academy Limited

Torgeir Halvorsen - Managing Director, Jæger Automobil

Coffee, Tea & Networking

Developing Lean Leadership Capability at GKN

Peter Watkins - Operational Systems & Business Excellence Director , GKN Land Systems

Nextworking Reception

Creating and Managing Successful Projects using Oobeya and Visual Management

Sandrine Olivencia - Lean Coach, Operae Partners and European Lean IT Summit Organiser

Building a Management System for Health and the Public Sector

Marc Baker - Lean Coach, Lean Enterprise Academy Limited

Ian Taylor - Lean Coach, Lean Enterprise Academy Limited

Developing Lean Leaders

Peter Watkins - Operational Systems & Business Excellence Director , GKN Land Systems

David Marriott - Lean Enterprise & Quality Director, GKN

How to Work End to End Across the Supply Chain

Steve Warren - Supply Chain Development Director, AkzoNobel Decorative Coatings

Saskatchewan Experiment - Health, Education, 3P and the Role of the Lean Team

Daniel Jones - Chairman, LEA

Dan Florizone - Deputy Minister of Education (Former Deputy Minister of Health), Government of Saskatachewan

The Role of the Lean Team in a Transformation

Ken Andrew - Head Lean Principles and Sustainability, Royal Bank of Scotland

Introduction to Day 2

Dave Brunt - Chief Executive, LEA

Lean Retailing - Transforming Car Retail in South Africa

Terry O'Donoghue - Chief Operating Officer, Halfway Toyota

Developing Lean Transformations

Dave Brunt - Chief Executive, LEA

Coffee, Tea & Networking

Developing Problem Solving Capability

Mark Davies - Senior Manager, Toyota Motor Manufacturing (UK)

Keith Edwards - Section Manager, Toyota Motor Manufacturing (UK)

Lunch

Developing and Deploying Hoshin Kanri at Jæger Toyota

John Kiff - Lean Coach, Lean Enterprise Academy Limited

Torgeir Halvorsen - Managing Director, Jæger Automobil

Coffee, Tea & Networking

Lean Enterprise: Starting Up, Growing Up & Starting Over

Jim Womack - Founder and Senior Advisor, Lean Enterprise Institute

Creating & Managing Successful Projects using Oobeya & Visual Management

Sandrine Olivencia - Lean Coach, Operae Partners and European Lean IT Summit Organiser

Building a Management System for Health and the Public Sector

Marc Baker - Lean Coach, Lean Enterprise Academy Limited

Ian Taylor - Lean Coach, Lean Enterprise Academy Limited

How to Work End to End Across the Supply Chain

Steve Warren - Supply Chain Development Director, AkzoNobel Decorative Coatings

Developing Lean Leaders

Peter Watkins - Operational Systems & Business Excellence Director , GKN Land Systems

David Marriott - Lean Enterprise & Quality Director, GKN

The Role of the Lean Team in a Transformation

Ken Andrew - Head Lean Principles and Sustainability, Royal Bank of Scotland

Where does Lean go next? Discussion with the Founders

Daniel Jones - Chairman, LEA

Jim Womack - Founder and Senior Advisor, Lean Enterprise Institute