Introduction

In my recent blog post “What is a Lean Management System?” we discussed the need for two key management systems in a lean organisation: One for Performance and one for Improvement. In this post we run through the steps required to develop performance management through a Lean management system example.

To recap, a Performance Management System is all about maintaining a standard level of performance for a process or activity. It uses a structured, connected, visual approach to monitor the performance, highlighting issues and reacting to them in a timely manner. This enables the business to run on a daily basis and sustain a defined level of output. It relies upon gathering accurate data about how a process is performing and having a method to close any gaps. This helps maintain stability and sustain any future step change improvements.

An Improvement Management System is about improving the level of performance for a process or activity. These are the methods that enable the organisation to make step changes in performance to improve its competitiveness over the medium and longer term. The activities are prioritised to align with the vision and goals of the business and focus on raising current performance levels through specific projects. It relies on thorough problem solving to identify these projects and action planning to make improvements happen.

Visualising the Performance Management and Improvement Management Systems

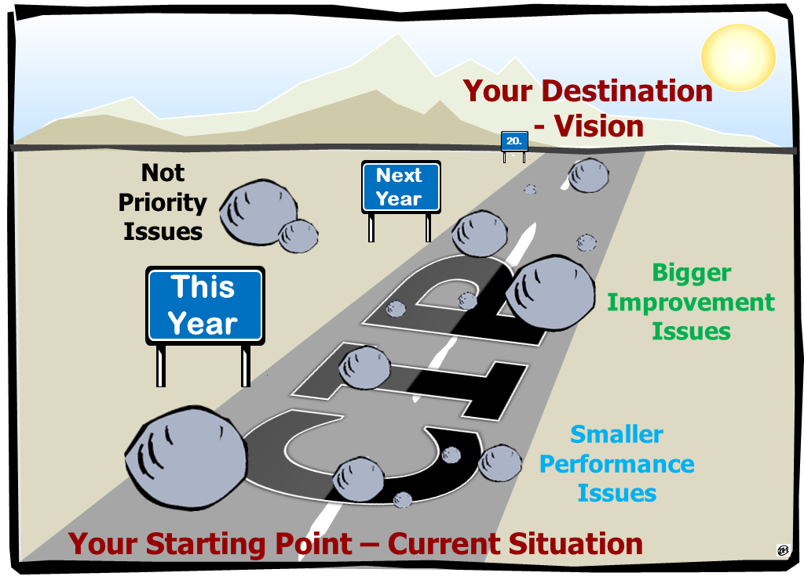

If we try to visualise these concepts in one picture, it might look something like this.

The road represents your Continuous Improvement Plan or path from where you are today to where you want to get to in the future. The road signs indicate how much progress you intend to make each year on that journey. As you can see, there are some rocks or obstacles on the road. These rocks represent problems. The smaller ones are those which crop up more frequently. Your Performance Management System addresses them to keep you on track. The larger ones are the more difficult problems. Your Improvement Management System addresses these in the form of improvement projects.

The rocks at the side of the road are those we decide as not priority issues for the time being. It’s often the most difficult decision to make, to deselect these. What are you not going to do? This visual goes some way to explain the background and significance of the two types of management systems.

Performance management is about stabilisation. Stability starts by defining a standard and managing to it – are winning or losing on an hourly, daily, weekly, monthly basis appropriate to your situation. Of course, some days will be better than others, but the point is we can see and understand where we are and react to get back in control. Having achieved a level of stabilisation, this then provides a foundation from which to make sustainable improvements. By doing this you will make improvements in the current performance and by making the work easier for those completing the value adding tasks, help engage them in the Lean approach.

Lean Management System Example

Part of our research with organisations is about defining problems and closing gaps. In our Learning value stream we have a world-wide “club” of Toyota dealers. They originally came together to learn how to apply the Toyota Way to their sales, service and parts operations. More recently a couple of them are working through the real life challenges of Toyota’s strategy of becoming a mobility company. What does that mean for customers and the dealer processes they are responsible for? Each is working to develop a Lean management system example.

Given the value driven purpose from Toyota, we are asking the question “What management system and leadership behaviours are required to support this new way of working?” It’s the question in the centre of the Lean Transformation Framework house. Here are the key steps they have been going through and the learning so far. The main aim being to create self-reliance on their lean journey.

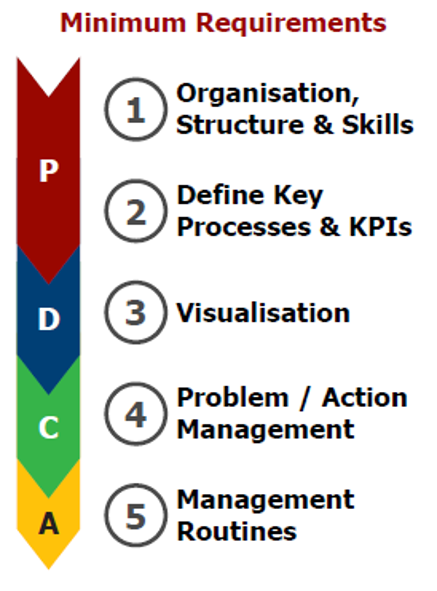

The plan we used to help the organization develop their performance management system is very detailed. Each week there is a 1 hour teach on a key aspect of the performance management system. Then there is homework and a 1 hour coaching session to check understanding, provide additional support and maintain progress. The covid pandemic has resulted in remote working only. As a result, we have worked on the management system remotely. This has been challenging because we usually insist on going to gemba (the Japanese term for the “real place” – where the work is done.) However, there are several benefits to supporting in this way, not least the opportunity for everyone to learn in small batches with a regular cadence. The structure is around the 5 elements of the performance management system.

5 Key design Elements to develop a Lean Performance Management system example

There are 5 key design elements to create a lean management system example. These are shown below. Organisation structure and skills; the KPI tree; Visualisation; Problem and Action Management and Management Routines. For each key design element, the leaders across the business (in 4 dealership sites) went through a teach to understand the current state and define a target state, identified gaps to close (between current and target) and then developed a plan to close the gaps – all using PDCA.

Organisation, Structure and Skills

The first of the 5 elements to tackle is organization structure and skills. Each area of the business worked from the front-line, assessing how they were organized to deliver value to customers. In some cases, team leaders were in place, but once teams realized the true purpose of a team leader, they changed their structure to reflect the need for leaders to be teachers and coaches of the Act-Plan-Do-Check performance process. To do this effectively their ratios of team leader to team member changed up or down depending upon the area. All done without increasing headcount or costs overall. With the team leader concept and the structure understood, team leaders then started to look at how they develop capability. We summarized the current state in a skills matrix or versatility chart, identifying the gaps to close.

Key Processes and KPIs

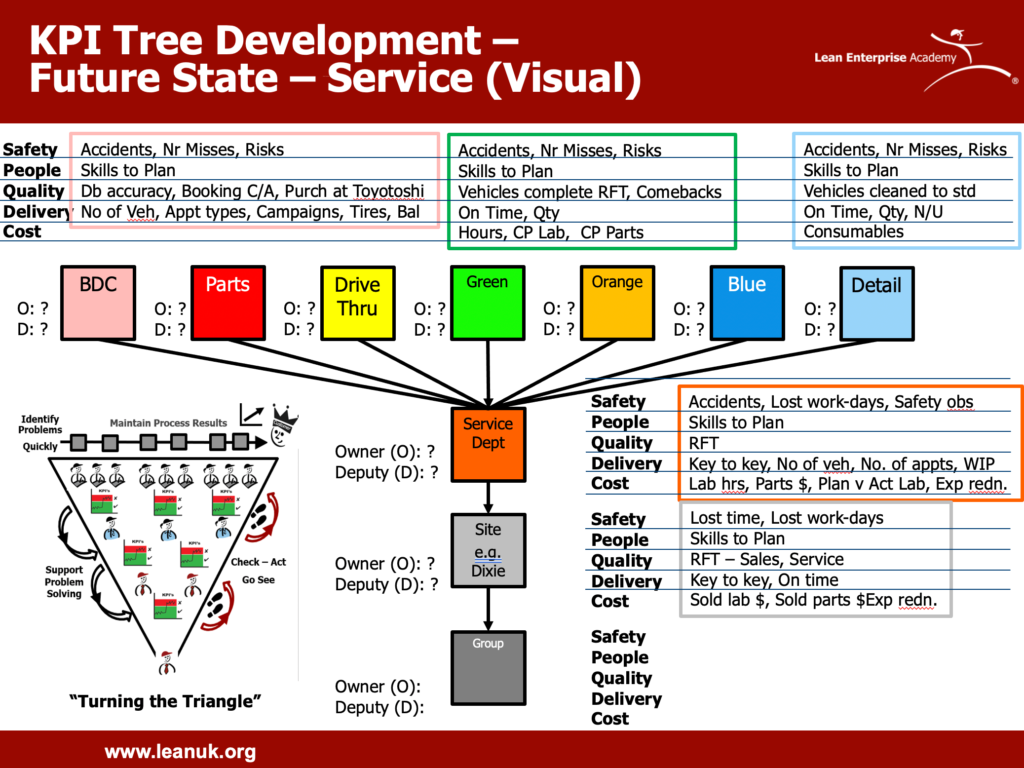

The second key element is the development of a KPI tree. Again we started by understanding the current state. The each level in the organisation develops the KPI tree. We organized from the strategy and from the definition of value to the customer, structuring the KPIs in terms of safety, people, quality, delivery and cost for each key process. As is typical we had lots (too many) result/cost KPIs but not many customer orientated and process metrics.

There are two dimensions to the KPI work – the horizontal flow of value to the customer and the interaction vertically through the organization. At the high-level, key to key – the lead time for the customer from dropping off to collecting the car is important. However, this means nothing to a technician doing the work in a bay. Here the relevant performance indicator is completing the work to takt time – in this case a 30 minute cycle.

Here is an example KPI tree for one area in one dealership. It’s the service department value stream. There are several teams in service. BDC who take bookings, parts department, the service reception “drive through”, the predictable work team (known as the green team – which service and repair predictable work under 30 mins duration), the orange team that health check vehicles, the blue team that do unpredictable jobs and the detail team that clean the service vehicles. Each team developed their performance management metrics which are fed to the service department manager. These in turn feed to the site KPIs and then to the Group KPIs.

Visualisation

With the KPI tree defined, each team then started to visualize these. The critical thing here is to not be too prescriptive, but to ensure that we capture and structure the vital few issues. Each frontline team captured their visualization following the 10 feet 10 second rule. They developed owners for each KPI – who would fill in the details before each meeting and they practiced the team meetings. Good visualization has the PDCA cycle embedded in it. It should display the problems the team is working on.

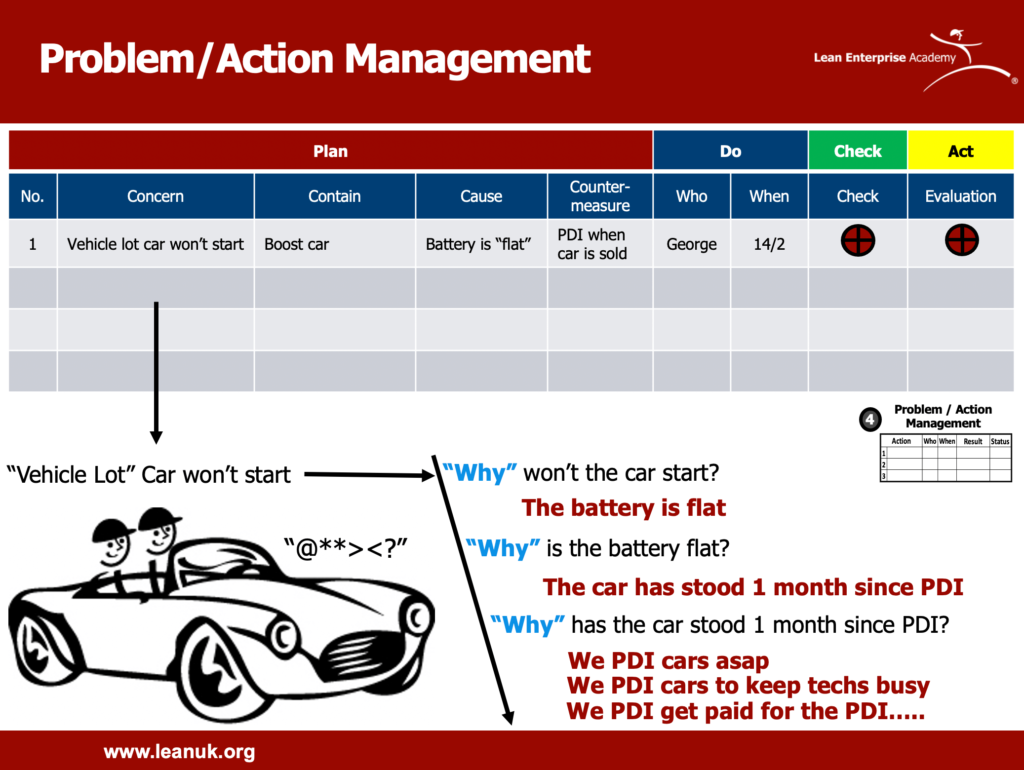

Problem / Action Management

A critical part of performance management is the identification and management of problems. We’ve discussed in previous webinars that the lean community has a problem with problem solving. The six sigma and “lean six sigma” community do too. They have made problem solving far too complicated. Not everything needs an A3.

Teams conducting daily performance meetings need a simple way to capture issues and ensure follow up. Here’s a great example that a sales team identified during an early sales meeting. They recognized that vehicles in the car park (or “lot” as they say across the Atlantic) failed to start. Everyone knew that the batteries drained and so needed a boost before the vehicle would start. However – using their board they realized this only “contained” the issue. The issue to address was identifying the root cause. Why didn’t the cars start? The team used 5 whys. Everyone knew the battery is flat, but they asked a further why. They realized that they overproduced – preparing cars before they were required. They ran an experiment where they only prepared a vehicle when it was sold. This reduced the number of boosts required saving everyone time.

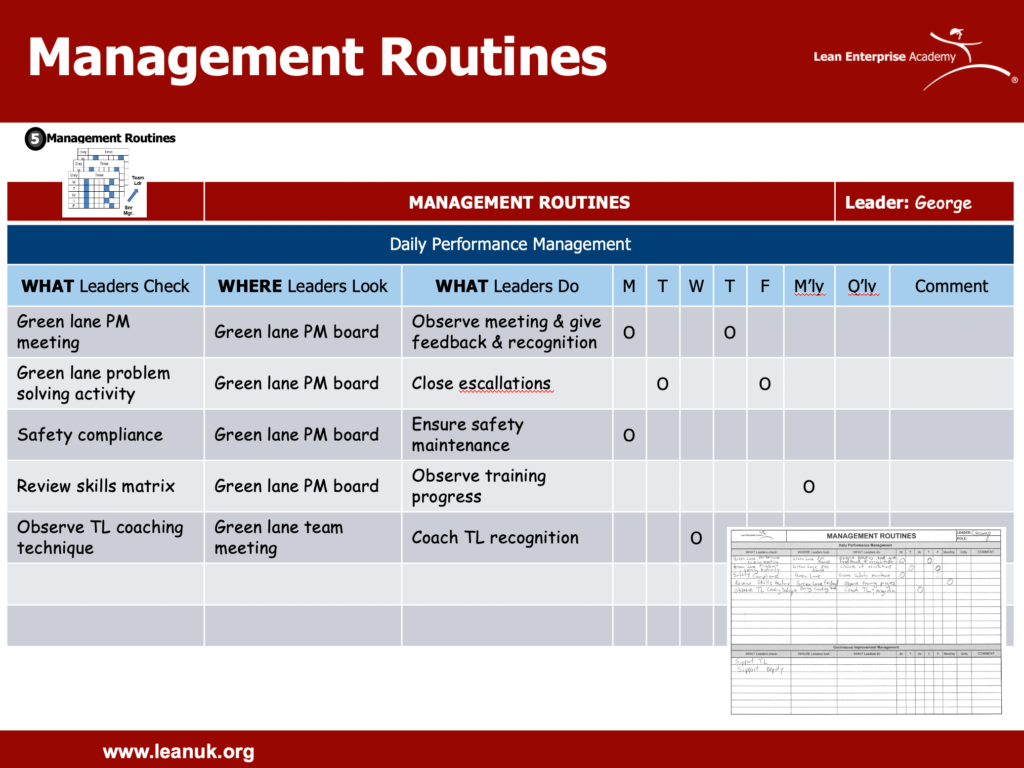

Management Routines

The last element is making some of the invisible work of management, visible. Each manager and team leader writes down their management routine in terms of what they need to check, where they need to look and what they need to do. Specific timing, be it daily, monthly or quarterly begins the process of developing standardized work for managers. It’s important here that we discuss and document not just WHAT is to be done, but HOW it is to be done.

This example, developed by one of the service managers, shows the activity required to support the green team that service predictable cars under 30 minutes duration in one store. Writing down the management routines provides the framework and structure for the leader’s activity to verify the performance management system and trigger when to provide recognition, teaching/coaching or constructive feedback. You create culture by changing what you do. This process helps provide a framework to embed the behaviours needed to work effectively within and across teams in turn changing what people do.

Lean Management System Example Summary

Developing a lean management system example is a journey. It requires multiple PDCA cycles. Arguably, the group did this at one of the most challenging times – in the eye of the covid pandemic storm. However the process has been hugely beneficial. They had their best ever tyre season – changing from winter to summer tyres and have increased profits in an overall declining market. More importantly, they are aware of gaps in day to day performance that need to be closed and have begun the process of solving problems much closer to the work. This is providing a level of stability that enables management to think through their next steps on their journey of supporting Toyota’s strategy of becoming a mobility company.