Earlier this month we published an article about lean learning on Planet Lean. In it, we discuss how lean can be applied to define learning processes. The example we describe comes from action research with JJ Churchill. They are a specialist first tier engineering company in the aerospace, power generation, diesel, defence, nuclear and med-teach sectors. To expand on the article, this blog includes a video of the report out from the first wave of problem solving conducted with them. The key concept behind the activity is to apply lean learning to learning lean.

At the Lean Enterprise Academy we have researched how companies best learn lean for 30 years. We even ran a whole Lean Summit on the topic back in 2016 titled Lean Learning, Learning Lean. Our conclusions then, as now, are that many providers of lean training, development and capability building are out of step with what is needed. Furthermore, customers and potential customers frequently place too much emphasis on qualifications and accreditation (such as certifications and belts) rather than learning through solving real problems.

Lean Learning

To understand what lean learning is, it helps to articulate with what lean is. At the Lean Enterprise Academy we define lean as “providing the most value from the customers’ perspective, while consuming the fewest resources and utilising the talents of the people who do the work.” On their global website, Toyota explain that Toyota’s production system (TPS) is “based on the philosophy of achieving the complete elimination of all waste in pursuit of the most efficient methods.” TPS has two pillars: Jidoka and Just-in-Time. Jidoka concerns creating a system (process and people) with the ability to detect when an abnormal condition occurs and immediately stop work. Just-in-Time concerns itself with making “only what is needed, when it is needed and, in the amount, needed.”

How do we apply jidoka and Just-in-Time to learning? Applying lean to learning means creating learning processes for people that have the ability to detect an abnormal condition and immediately stop work, building quality into the learning process and into the pupil. Learning “just-in-time” means learning what is needed, when needed and, in the amount needed. In addition for learning to be lean, ongoing kaizen (continuous improvement) must be applied – to steadily simplify the learning process.

How do you Kaizen your Learning Processes?

Steve Glaveski argued the need for lean learning. In his 2019 HBR article “Where companies go wrong with Learning and Development” the author argues we are learning:

- For the wrong reasons

- At the wrong time

- The wrong things

And

- We quickly forget what we have learned

At the Lean Enterprise Academy we have identified each of these failure modes and a number of gaps in learning performance. In an attempt to close those gaps we took one lean subject area, problem solving. We designed a number of experiments to see if we can improve capability transfer and development. We chose Problem solving because it is a fundamental skill required by any organisation or individual on a lean journey. Here we describe one such experiment.

Background to JJ Churchill

JJ Churchill is a specialist engineering company with over 80 years of experience. They demonstrate expertise in new product development, volume manufacture and spare part production.

The company is a Tier 1 supplier to the aerospace, power generation, diesel, defence, nuclear and med-tech industries. JJ Churchill works with advanced materials, geometries and technologies. We enlist the work of talented engineers to produce parts with superlative repeatability. The headquarters, in the town of Market Bosworth, UK, sits on 1.6 hectares with the workshops covering 5,000m2.

JJ Churchill’s “Problem to Solve” & the “Process Used”

The organisation wanted to develop problem solving capability for supervision and apprentice engineers. We agreed to teach our “Rapid problem-solving method” to a cohort of 12 participants.

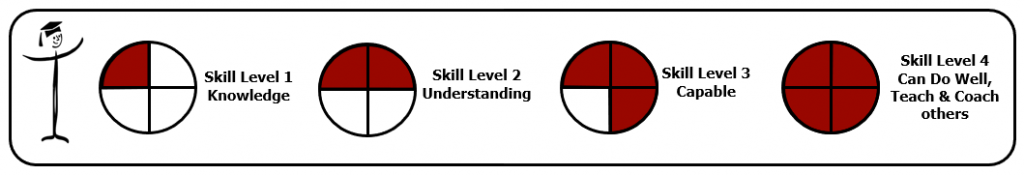

To both standardise the process and make available learning materials, when needed and, in the amount needed, LEA has developed an online learning platform. Structured around the Lean Transformation Framework, the Lean Learning Journey process is based around four skill levels:

1. Knowledge.

2. Understanding.

3. Capable.

4. Can Do Well, Teach & Coach Others.

The aim of the process is for the customer (in this case JJ Churchill) to become capable in the skill chosen and self-reliant so they can share learning and develop others in their team. Lean learning is a journey. Therefore, the approach we used blends LEA’s online learning platform to get a basic understanding of the concepts with coaching on real problems. In this case the process lasted eight weeks, starting in January 2022.

Firstly, people used our online learning platform to get a basic understanding of the concepts (what we refer to as Level 1). A week later LEA Senior Lean Coach David Marriott went back for face-to-face teaching, delivered using our teach posters and a case study the participants could practice on. The group was divided in four teams of three people. They went out on the gemba to find a problem to solve.

Leaders as teachers

For a sustainable Lean Transformation, we are strong believers in the concept of “Leaders as Teachers”. That is leaders who take the time to teach and coach their team, on the job to develop their capabilities rather than relying on separate function(s) to do it for them. The benefits of doing this are huge in terms of advancing your lean journey better, faster and cheaper. The challenge is how to provide materials that enable leaders to do that.

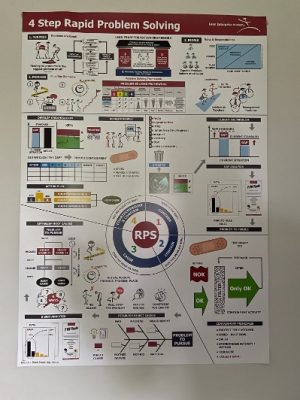

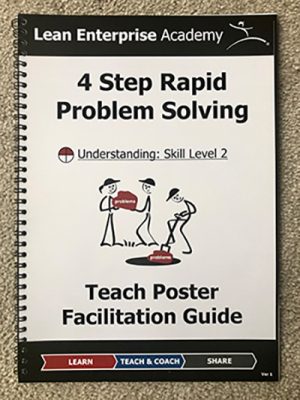

We find that the Teach Poster concept works best. Rather than a 100-page PowerPoint slide deck, we have tried to distil the subject matter down on to one piece of paper – a bit like an A3!

The benefits are that the approach is much less daunting for leaders to use and also much more informal than sitting down in a class room looking at a screen. All the Posters have a similar layout and structure making them easy to follow and remember. Images/pictures (rather than words) stimulate interest and discussion. There is a facilitation guide for each poster covering the “Important Steps”, “Key Points” and “Reasons” for each of the images. This assists the Leader when starting out to Teach. Finally, the Poster is available in the workspace as a visual reminder.

What sort of problems did the teams tackle?

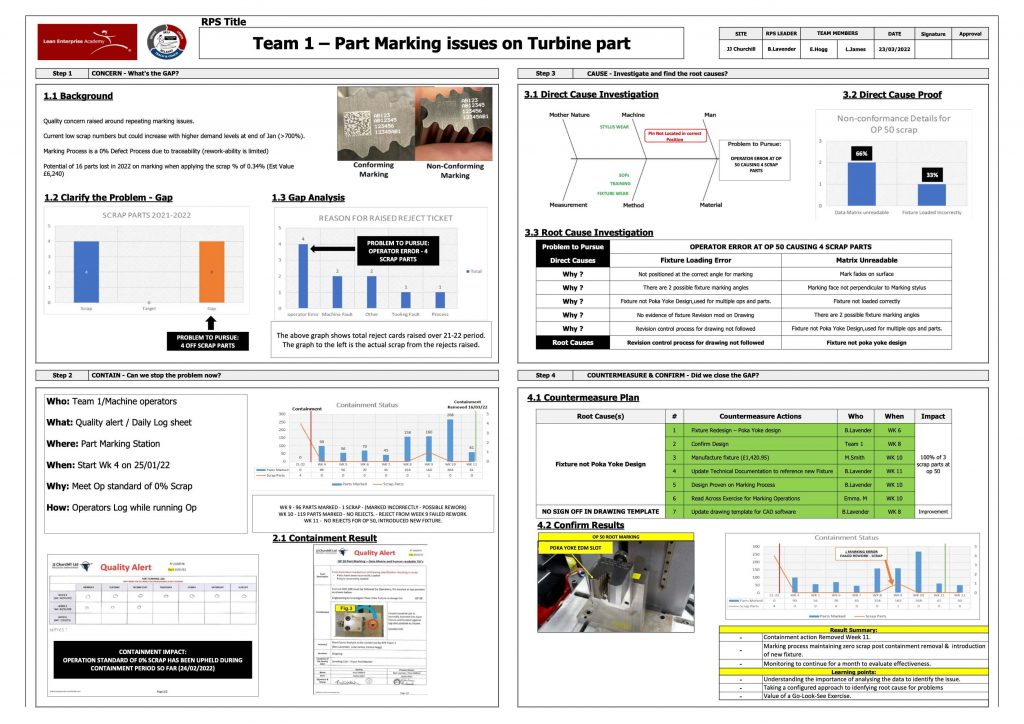

Three out of four projects heavily focused on quality – particularly scrap and defect reduction. Deeper learning occurred in that following analysis participants carried out on the shop floor they became aware of the importance of developing robust standards people can refer to. Examples for each of the three quality-related projects include standards on when a machine needs intervention to put it into specification, the level of magnification to be used in inspecting a product and how to insert a part into a fixture. This latter problem, for instance, was solved with the introduction of a clever poka-yoke (mistake-proofing system) shared across the business.

4 Step Rapid Problem Solving Report Out.

JJ Churchill Team Member presenting their Step 1: Concern

The fourth project related to EDM (electrical discharge machining) and on the operational improvement of the set-up time of one of the machines. The team studied operators over two shifts. As a result, it became apparent that the set-up was performed by engineers, rather than the operators themselves. The reason was that there were specifications – for instance on what tools to use – but no standard procedure on how to do it and in what timeframe.

Specifications are not enough; you really need to understand the work and the training people receive needs to reflect that. Indeed, across all four problems, it was clear there was a capability issue. The theory was there (extensive training had been provided), but it was often hard for people to put it into practice.

What were the results?

Sarah Gregory: We carried out a management report-out. The teams explained their improvements and learning to the management team. We were all very impressed.

I can tell you that one of the projects will likely deliver savings in the region of £40k, in terms of product and management time. We have also seen a reduction in our scrap rates. Most importantly, we have seen big gains in terms of customer satisfaction and right-first-time.

As a management team, our big realization was that we need to do even more to train our people and ensure that training leads to capability development. This is now a key deliverable for me.

It’s been great to see how these solving problems has a real impact on the people working at JJ Churchill. To give you an example, an operator running the machine one of the improvements focused on emailed the team responsible for the change, thanking them for making his life easier. It’s this kind of benefit that will ultimately allow our new approach to problem-solving to spread across the company.

All the posters are on display on the shop floor, on our Achievements Board, for everybody to see. This way people can see the improvements made. We are sure they will be inspired by them. Besides, we think it’s fundamental to celebrate the successes the teams have had.

We organise sessions for the groups to discuss with senior management activities since the improvements. We look to see whether the approach is relevant to other problems. The organisation is currently identifying our next group who will go through the next development session.

Developing Lean Thinking as part of personal development

Pparticipants were younger people who haven’t had much prior exposure to Lean Thinking. The process is therefore a great way to develop Lean Thinking as part of personal development. We believe that developing one’s ability to learn is not a “lean thing”, it’s a life skill that people are lucky to work on so early in their careers. In our minds, this should be a much bigger focus in our education system and in our businesses. The people at JJ Churchill told us that they did not expect to learn so much. They are thrilled with the results they can achieve.

Learnings for the Lean Community from the Approach

We have known for a long time that many companies tend to treat – especially larger ones – lean as a “program”. Participants typically get an introduction to Lean Thinking, play games, maybe do a simulation, but then they don’t know what to do with any of it. This lean-in-a-box promises a lot but often under-delivers. Lean isn’t a project that you can separate from the way you manage and develop your organization.

At LEA we have a different approach: We want people to realise that learning is a journey. One that they can shape and design. A series of learning processes they can follow that take them to a deeper level of learning and capability each time they practice. The point is not to be certified at the organization or individual level through competency systems or belts. Those are products developed by service providers to generate money for them. They rarely provide value and capability for the customer. There’s more to come on this as it’s a current area we are researching.

Lean learning needs to encompass jidoka and Just-in-Time. We can’t build quality people if we don’t build quality into our learning processes. Delivering Just-in-Time requires delivering learning in small batches (organised in the four levels – Knowledge; Understanding; Being Capable; Can Do Well, Teach & Coach Others). To develop capability you must practice, with a cadence. This moves learning from push to pull based. This, in turn, leads to discovery on the part of the learner.

Using the Lean Learning Platform

The purpose of the Learning Platform is to provide structure for the learning journey. With it, we want to achieve two things:

- Make lean learning accessible for people (both in terms of cost and ease of use.)

- Free up time for everyone – whether that’s the learner, an organisation’s internal managers or lean coaches, or our own coaches.

We (and many of our partners) have very experienced coaches. We have developed re-usable learning material people can use on their own. This frees up the coach to coach and challenge an organization’s existing thinking. That’s where coaches can provide the most value, by helping people to put what they learn into practice. Blending great coaching with great material and a platform that allows people to pull learning as they need it is really where we believe we are making a difference.

Internally, we can practice what we preach. We have a standard for learning materials which we apply kaizen to. We also have a standard for the learning process. we can configure this to meet an individual customer’s needs.

Before we introduced the platform, we wouldn’t have been able to support JJ Churchill as effectively (in terms of quality, delivery and cost) as we did. We believe that our teaching material and a defined learning process really makes the difference. It moves organisations beyond “projects”, in terms of both capability development and business benefits.

A Customer Viewpoint

Sarah: I first got involved in Kaizen in the early 1990s and I have seen my fair share of lean initiatives over the years. For me, the key benefit of the LEA approach was their absolute focus on helping people get out of “solution mode” and concentrate on proper problem identification. Most approaches I have seen before have you jump to solutions, only to see them not working and being sustained.

Having David Marriott as our coach on site really worked from a facilitation point of view. Not only did he help us to put teachings into practice in real time, which made a huge difference, but he also consistently challenged our way of thinking. That was so refreshing and different!