We are often asked to evaluate how lean an organisation is. How far it has progressed down its lean journey and what its next steps should be. An obvious place to start is to go and take a walk through its core activities to see what they have actually done. This quickly reveals whether they have been able to go beyond lean tools and point Kaizen to make their value streams flow. Looking at their visual management also reveals whether line managers are actually using this to manage progress, to respond to interruptions and to record persistent problems for root cause analysis later. As you talk to employees you also quickly discover how many lean seeds have been sown and how many lights have gone on in their heads. In other words how many employees have been infected with lean, process thinking and would not want to return to the “bad old days” before lean.

But this is just the start. The main problems and obstacles in going lean are rarely on the shop floor but usually higher up the organisation in management. The shop floor is indeed a reflection of management. Here you also see whether top management just sees lean as a way of engaging employees in seeing and eliminating waste, by deploying lean tools right across operations. Or whether in fact lean improvement activities are being focused on closing the key performance gaps that are critical to the success of the organisation, by redesigning both the products and the processes that make and deliver them to customers.

Having defined the scope of the organisation’s lean ambitions we now need to look at their approach to change management. In most cases this will be defined by which consulting approach they used to get started. Who they used will be a good indication of where they are likely to get stuck on their lean journey. The 16 week model line approach is unlikely to last long after the consultants have gone as the organisation will not have learnt enough to replicate it elsewhere. The go to Japan trips to get religion and learn how to do Kaizen approach is also likely to run into the sand once the finance director begins to examine the costs. The repeat Kaizen week approach often goes hand in hand with an over reliance on outside experts so that the results are not always connected, sustainable or owned by the organisation.

Organisations have to develop the ability to build their own lean knowledge and examples as well as scouring for lean knowledge from elsewhere. This means getting as many experiments going in different pieces of the organisation as quickly as possible and then cross learning and building upon the lessons learnt. It does not, as we witnessed in one multinational, mean giving a team of high fliers at HQ a year to develop their one best way and to plan its roll out across the world. Lean is not a programme and has to be learnt by doing – and adapting to different circumstances and cultures.

So, realizing the full potential of lean means building a learning organisation on the one hand and a lean management system to drive it forward on the other But again beware, it is not enough for instance for the organisation to be doing policy or strategy deployment or using A3 analysis of its key value streams or teaching employees how to use A3 reports. It is the quality of the analysis, the decisions and the learning that emerge from them that really counts. Let us take each one in turn.

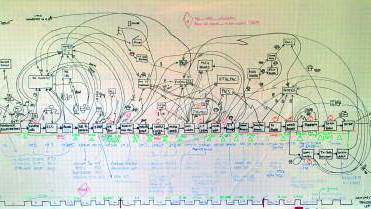

Narrowing down the critical root causes of the broken value streams that fail to deliver the required performance for the organisation is not easy. Deselecting the many other possible improvement activities in order to focus efforts on the vital few that will make the biggest difference to the organisation is even harder But without this a lot of effort is wasted and a lot of potential performance improvement is missed. The point of policy or strategy deployment is to align improvement activities across the organisation to solve the critical business problems facing the organisation.

Making Hospitals Work describes how a top team in a hospital go through such an analysis. In their case discovering that streamlining the flow of emergency patients and reducing length of stay is the way to meet government waiting targets, improve infection rates and free up capacity to do more and more profitable elective operations with the same resources. This is precisely the area most outside consultants are reluctant to tackle.

In exactly the same way we would look for evidence of similar thinking emerging from the policy or strategy deployment process. For example, whether a food processor recognises that making their high volume products every week in line with demand instead of in big batches to forecast every 14 weeks is the key to freeing up the cash by cutting inventories in their pipeline from 100 days to 10 and meeting all orders from retailers on time and in full. Or whether an auto parts maker begins to understand and tackles the excessive costs of its parts that travel tens of thousands of miles across the globe between its plants before finally reaching its customer some 40 weeks later

Optimising the pieces does not add up to optimising the overall flow of work. These examples point to a second key dimension of lean management, whether it takes an end-to-end perspective. Has someone been given the responsibility for gathering the facts and gaining agreement from key parties to improve the key end-to-end value streams? Do the metrics driving behaviour also include the performance of the value stream as a whole and is there a mechanism for surfacing and resolving conflicts between departmental and value stream objectives? Do managers have a way to see how to free up cash, reduce cost and save capital expenditure along the core end-to-end value streams?

Finally is the organisation really building an experience base in problem solving amongst its key employees? Are senior managers teaching their junior colleagues how to think through a dialogue as they build a robust A3 plan to solve a business problem? In a very real sense scientific problem solving is the foundation of lean, evidence based management. Perhaps the biggest disappointment we have come across is where employees and managers can’t clearly define the business problem they are trying to solve using lean. This is why the first question we usually ask is “What is your problem??”