Any seasoned Lean Thinker will have heard or used the phrase, “What problem are you trying to solve?” But is the art of problem solving getting lost amongst the noise of the numerous methods and approaches organisations and individuals use to go about “solving” the issues faced day to day?

When we first introduced workshops and coaching on A3 Thinking in the early 2000’s one of the most common questions (and misunderstandings) folks had was when they should use an A3. Indeed as we coach folks we frequently find that the A3 has descended to be used for everything – a catch all process. That in itself is a problem. Without understanding the right circumstances to use an A3, the process can, in extreme cases, become a “tick-box” exercise for folks to go through. The opposite of what it is intended for.

Whilst organisations and individuals can get back to basics and, through some rework, improve their understanding of A3 Thinking I’ve always felt there was a need to explain the various methods we can use to “solve” problems, all of which should incorporate Plan-Do-Check-Act to some degree. Art Smalley, author of Creating Level Pull, Understanding A3 Thinking and Toyota Kaizen Methods did just that in his latest book – Four Types of Problems. However Art went one stage further – good Lean Thinkers always do – by providing a taxonomy to the problems we encounter. If we understand the types of problems, we stand a better chance of applying an appropriate process to “solving” them. Thus we avoid the issues in the famous quote from Abraham Maslow, “I suppose it is tempting, if the only tool you have is a hammer, to treat everything as if it were a nail.”

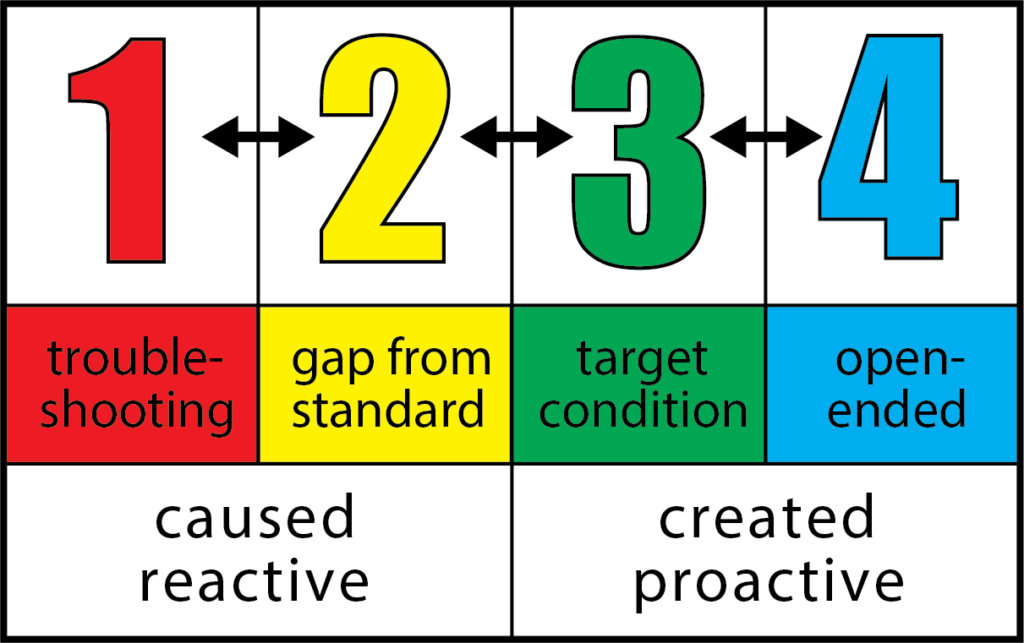

In Four Types of Problems, Art Smalley shows us how to break the “hammer-and-nail” trap. He demonstrates that most business problems fall into four main categories (see the diagram above), each requiring different thought processes, improvement methods, and management cadences:

- Troubleshooting: A reactive process of rapidly fixing abnormal conditions by returning things to immediately known standards.

- Gap-from-standard: A structured problem-solving process that aims more at the root cause through problem definition, goal setting, analysis, countermeasure implementation, checks, standards, and follow-up activities.

- Target-state: Continuous improvement (kaizen) that goes beyond existing levels of performance to achieve new and better standards or conditions.

- Open-ended and Innovation: Unrestricted pursuit through creativity and synthesis of a vision or ideal condition that entail radical improvements and unexpected products, processes, systems, or value for the customer beyond current levels.

“Organisations and individuals at all levels fall into this trap of having one primary or standard way of solving every problem,” said Smalley, who learned problem solving at Toyota’s historic Kamigo engine plant from Harada-san, who led the maintenance activities that created the stability needed for Taiichi Ohno’s innovations in the Toyota Production System. You can read a great piece on Planet Lean in which Joe Lee reflects on working with Harada- san, called “Passing down TPS across generations” which coincidently was published this week.

For those wanting to learn more about Art’s book, Four Types of Problems is available in our updated bookstore as are Art’s other publications. One of the benefits of our new website is the ease with which we can introduce products! It’s led to a review of what we stock and what information we provide when you purchase. We are building a database of useful articles, videos and learning materials that we can send to you to help you learn from our most popular books when you purchase from us. It’s our way of providing more value and saying thanks for purchasing from us rather than going the Amazon route. Every book you purchase from us enables us to conduct our research, develop the website and create new products and services.

Finally, for those wanting to hear what Art has to say about problem solving, you can watch his presentation from our 2016 UK Lean Summit by clicking on the video (above.)