Introduction

LEA has continually conducted experiments to develop ways of explaining the key concepts of Lean with higher quality in a shorter lead-time.

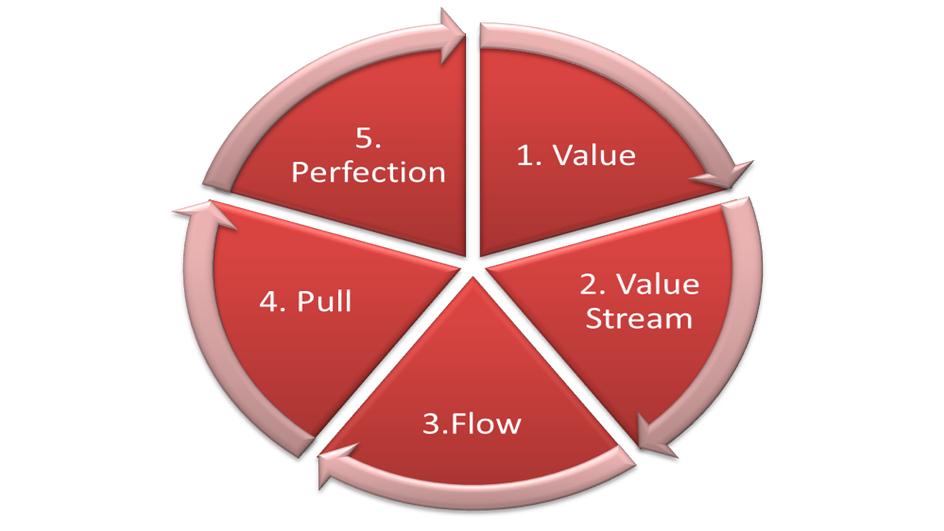

In this workshop we use a simulation to help any organisation understand the five Lean principles – value, value stream, flow, pull and perfection – whilst integrating the concepts of purpose, process, people and the scientific method of PDCA.

BOOK ONLINE NOW – Hit the red Register Here button at the bottom of the page

DOWNLOAD THE BOOKING FORM HERE – then email it to [email protected]

DOWNLOAD THE WORKSHOP PDF TO SHARE WITH YOUR TEAM

Objectives

The purpose of this workshop is to:

- Provide a method to grasp the key concepts of Lean in an effective and efficient way

- Show participants the key concepts of how to define and solve business problems at all levels using the PDCA model and to sustain the improvements

- Develop participants’ ability to practice or teach Lean

Agenda

- Introduction to the Key Concepts of Lean

- 5 Lean Principles: Value, Value Stream, Flow, Pull, Perfection

- Simulation learning exercises including:

- Learning to See Waste

- Batch & Flow

- Pull & Supermarket

- Applying Continuous Improvement & PDCA

- Key Role of Leadership

Topics that will be examined include

- Purpose, Process, People and the Lean Transformation Framework

- Customer value – Contrasting Customer Satisfaction with Customer Fulfilment

- Value and Waste and the five Lean principles

- The 8-Step / PDCA problem solving process including some of the key tools for:

- Clarifying and breaking down the problem

- Grasping the situation including mapping and analyzing the causes

- Sustaining the gains and revealing other problems

Workshop Benefits

Through instruction, discussions, a video workshop and a simulation activity, participants will learn the importance of:

- Understanding and focusing on customer value at every step and seeing the link between customer purpose and business purpose

- Resolving problems in a structured way

- Using PDCA to sustain the improvements effectively

Related Books

Who Should Attend?

Individuals with little to moderate experience of Lean who are looking to increase their understanding. Managers who want an understanding of the total scope of implementing Lean. Managers who want to improve their communication of Lean.

Notes

- Attendance – 1 Day Course

- Class size – Maximum 12 people per day

- Timings – Each day will run from 09:00 – 17:00

- Cost – £395.00 (Consultant Rate £450.00)* per delegate per day with a 15% discount when 2 or more people from the same organisation attend

- Materials – A PDF copy of the materials will be available via the Lean Enterprise Academy website. Participants will also receive a copy of Lean Thinking by James P. Womack and Daniel T. Jones

- Facilities** – Refreshments and lunches will be provided by LEA

* Please note prices exclude VAT at the standard rate of 20%

** We are situated in a listed building which unfortunately does not have disabled access. On occasions where disabled access is required we will move the workshops to a local hotel in Ross on Wye.

We can also run these workshops in-house at your convenience, if you would like to explore this option please contact us at [email protected] or call +44 (0)1600 890590

*** Why not combine this workshop with the ‘Introduction of Lean Transformation Framework’ to learn about the various approaches to improvement, common pitfalls to Lean Transformation and the key factors required for successful Lean Transformation ***

Follow up (optional)

LEA provides an ongoing mentoring service for organisations involved in making Lean transformations. Lean Transformation Master Plans, supporting A3s & VSM’s developed by the organisation can be reviewed at 30/60/90 intervals. This provides the organisation with help and direction in sustaining the learning from the workshop process and helps highlight further learning opportunities that can be pulled, as and when required, by the organisation.

Other workshops available – please visit our events page for more details

The lessons learnt during this workshop fit within the Basic Thinking, Mind-set and Assumptions element of the Lean Transformation Framework