The evolution of Toyota’s practices

Daniel T Jones (1)

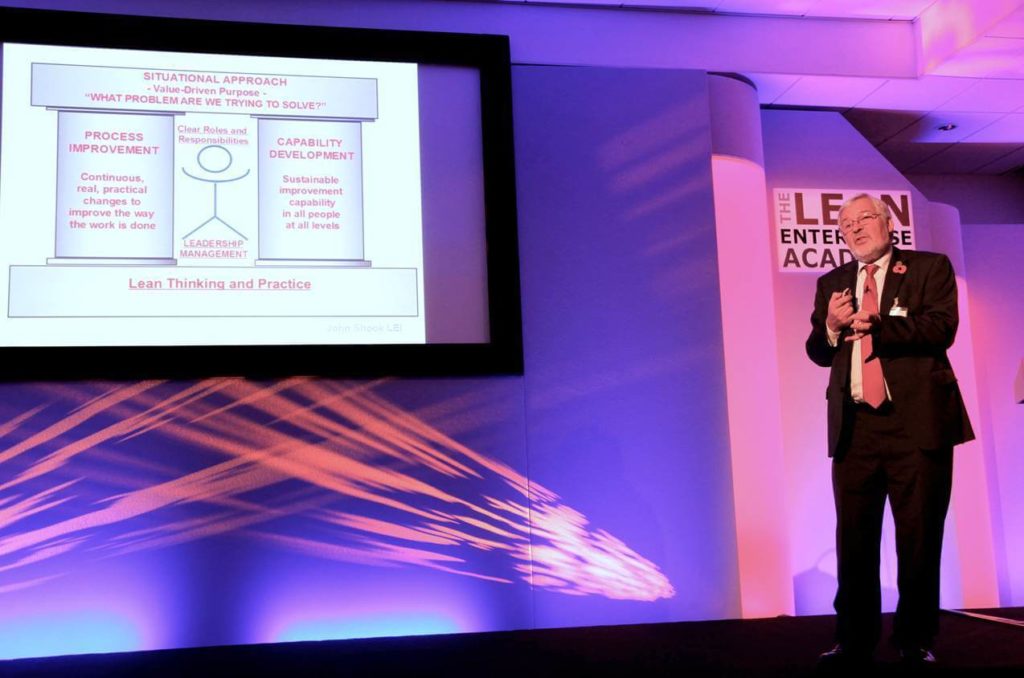

Lean thinking and practice are generic versions of the Toyota Production System (TPS) and the Toyota Way management system (2). Lean did not derive from theory but through observing practices at Toyota that were delivering superior performance in terms of product quality, efficiency (hours per car) and time to market for new products, leading Toyota to eventually become the largest car maker in the world.

The problem the founder of TPS, Taiichi Ohno, was trying to solve in the 1950s was how to build several different products on the limited equipment that Toyota could afford at that time. Instead of resorting to producing in batches he carried out many pioneering experiments to build an integrated production system that was able to make a variety of products in single-piece flow in line with demand. This challenged the assumptions that there is a trade-off between quality and productivity and that bigger batches lead to economies of scale and lower costs. His experiments also led to the development of many new tools, such as Kanban pull systems and SMED quick changeovers (3). Ohno also built on Toyota’s Jidoka system for making abnormalities visible immediately, invented in the 1930s.

However the distinguishing feature of Ohno’s approach was to challenge and teach front line and support staff how to design their own work, using the Training Within Industry system pioneered during WWII in the USA (4). This enabled the front line to establish a standard way of doing their work as a base line for improvement, which in turn enabled them to see and respond to any deviations from this standard immediately. In analyzing the root causes of the many issues that interrupted their work he also taught them how to use the scientific approach to solving problems, using Deming’s PDCA method.

Indeed it is the repeated daily practice of PDCA that develops the capabilities of individuals and teams to continually improve their work and improve the performance of the system as a whole. Toyota is often quoted as saying it “makes people in order to make cars”. These enhanced problem solving capabilities enabled Ohno to link activities together, remove all kinds of buffers and delays and with much shorter lead times to use simpler planning systems driven by demand rather than by forecasts. This accelerating continuous improvement system is called Kaizen (5).

Similar logic was used to develop very different approaches in other areas of the business including managing product development projects, production engineering of right-sized tooling, supplier coordination and sales and marketing. Eiji Toyoda, the long-time Chairman of Toyota, also used these principles to build a management system to support Kaizen and to focus and align activities towards key corporate objectives, called the Toyota Way (6). Again the key to doing so is building common capabilities at every level of management to plan and solve business problems using another version of PDCA, called A3 thinking (7).

The evolving understanding of Lean

TPS was developed in the 1950s and was taught to its suppliers in the 1970s and brought together as a management system in the Toyota Way in 2001. It continues to evolve as Toyota faces new challenges today. Likewise our understanding of Lean has deepened over time. We initially benchmarked their superior performance and coined the term Lean to describe this system in The Machine that Changed the World (8). This caused quite a stir across the global auto industry and beyond.

But it quickly became apparent that simply collecting and training all the lean tools was not enough for others to follow Toyota’s example. So Jim Womack and I set out to observe Toyota’s practices in more detail and those of other pioneering organisations who had learnt directly from Toyota. From this we were able to distil a set of five principles behind a lean system and a common action path to realise them in Lean Thinking (9). This triggered a wave of interest from practitioners across the world and led us to establish the Lean Global Network of non-profit institutes to describe and teach these methods across the globe (10).

One of the insights from this research is that no one can see or is responsible for the horizontal sequence of activities that creates the value customers pay for, from concept to launch, from raw material to finished product and from purchase to disposal. Vertically organised departments instead focus solely on optimising their activities and assets to make their numbers.

To help teams to see the end-to-end processes or value streams they are involved in we used another Toyota tool, which we called Value Stream Mapping (11). As teams map their value streams they realise the problem is not the people but a broken process and having stabilised their own work they now see new opportunities for collaboration to improve the flow of work and align it with the pull from real customer demand.

In industry after industry we have seen value streams that used to take many months from beginning to end now take a matter of days, with far fewer defects and more reliable delivery. This is only possible because front line staff know how to react quickly and tackle the root causes of problems that will arise in any tightly synchronised and interdependent system. It is also much easier to adapt to changing circumstances. Over time these emergent capabilities achieve superior performance than systems designed and supported solely by experts. This is the main difference between Value Stream Analysis and Business Process Reengineering.

The other insight is that the traditional approach to managing by the numbers and through functional politics at HQ wastes a lot of management time, fails to align activities with corporate objectives, hides problems and takes management away from front line value creating activities. Relying on expensive enterprise systems to force compliance with the command and control instructions from the top has in many cases made things worse and much harder to adapt to changing circumstances.

Toyota use a very different strategy formulation process, called Hoshin Kanri, to define the overall direction of the organization and to conduct a dialogue up and down the organization on proposed actions to achieve it, again based on PDCA (12). As a result resources and energies are prioritized and aligned through a visual process that reaches right down to the front line. This also lays the basis for collaboration across functional silos. Management in turn spends a lot more time at the front line, understanding their issues, eliminating obstacles and coaching problem solving. In this way management learns by helping colleagues to learn and does this by asking questions rather than telling them what to do. This builds very different behaviours and an environment where employees are challenged to fulfil their potential (13).

The spread of Lean and Lean Consumption

Lean thinking and practice has spread across almost every sector of activity, from retailing and distribution, discrete and process manufacturing, service and repair, financial services and administration, construction, software development and IT, healthcare and service delivery in government. It has even created a framework for improving the viability of digital startups (14). While the focus on value creation, value streams and learning have been common the sequence of improvement steps varies for different types of activity. However lean practices seem to work equally well in different cultures.

The full potential of lean is realized when it is embraced by the whole supply chain. Toyota’s aftermarket parts distribution system is still the global benchmark supply chain, delivering near perfect availability of the basket of parts at the point of use with only a tenth of the lead time and inventory in the pipeline from the point of production (15). Not surprisingly this inspired retailers like Tesco and Amazon to develop their own rapid response distribution systems that are essential for convenience retailing and home shopping. Manufacturers like GKN have also moved away from concentrating activities in focused factories in distant low cost locations to creating rapid response supply chains to serve customers in each region (16). GE is also using lean to design a new product range and production system for household appliances in North America, bringing this activity back from the China.

While most of the attention has been focused on the upstream supply chain, lean actually begins with the customer’s use of the product or service. In Lean Solutions Jim Womack and I developed a framework for using lean to define value from the user’s perspective (17). Consumption is in fact a series of processes that interact with the provider’s processes. Mapping both processes reveals where they are broken and cause mutual frustration and unnecessary cost. This reveals opportunities for improving user experience at lower cost and even new business models. In the digital age it is now possible to track the customer’s use of the product or service and enter into a two way dialogue with them. In a very real sense customers and users are becoming an important part of the supply chain delivering today’s products and services and co-developing tomorrow’s solutions.

Conclusions

From the above it should be clear that lean is not just another improvement methodology, but a very different set of behaviours and management system. It is not just a set of tools for production operations in the auto industry, but a much broader framework for creating more productive value creation systems in all kinds of sectors and activities. Readers should beware of the confusion that is caused by partial descriptions of lean, that often miss the key elements that make it work as a system.

Lean shares the same scientific approach to the analysis of work with many improvement methodologies, like BPR, Six Sigma and TQM. But it differs from them in how it is used. Rather than experts using scientific methods to design better systems, lean builds superior performance by developing the problem solving capabilities of the front line, supported by a hands-on management system.

Lean is therefore a path or journey of individual and organizational learning and leads to more challenging and fulfilling work for those involved. It is learnt by doing it and through repeated practice rather than by studying books or in the classroom. While it is driven by practice and not theory, Lean raises many interesting new hypotheses about learning and collaborative working for different academic disciplines to think about and research.

References

- Daniel T Jones is the Founding Chairman of the Lean Enterprise Academy in the UK www.leanuk.org and the Lean Global Network www.leanglobal.org and co-author with Jim Womack of the core books on Lean Thinking.

- The original texts are Taiichi Ohno, The Toyota Production System, Productivity Press, Oregon, 1988 and The Toyota Way, Toyota Motor Corporation, Tokyo, 2001.

- For a full description of all lean terms see The Lean Lexicon, Lean Enterprise Institute (LEI), Cambridge, 2003, The use of these tools is described in a series of workbooks published by LEI, including Creating Continuous Flow, 2001, Making Materials Flow, 2003 and Creating Level Pull, 2009.

- For a description of TWI see Donald A. Dinero, Training Within Industry, Productivity Press, New York, 2005.

- Masaki Imai, Kaizen, McGraw Hill, New Yoruk, 1991.

- Jeff Liker, The Toyota Way, McGraw Hill, New York, 2004.

- John Shook, Managing to Learn, Lean Enterprise Institute, Cambridge, 2009.

- James P Womack, Daniel T Jones & Daniel Roos, The Machine that Changed the World, Rawson Macmillan, New York, 1991.

- James P Womack & Daniel T Jones, Lean Thinking, Simon & Schuster, New York, 1996 and 2003.

- www.leanglobal.org.

- John Shook and Mike Rother, Learning to See, Lean Enterprise Institute, Cambridge, 1998,

- Pascal Dennis, Getting the Right Things Done, Lean Enterprise Institute, Cambridge, 2009.

- This management system is described in Jeff Liker and Gary Convis, The Toyota Way to Lean Leadership, McGraw Hill, New York, 2012, Mike Rother, Toyota Kata, McGraw Hill, New York, 2010 and Michael and Freddy Balle, Lead with Respect, Lean Enterprise Institute, Cambridge, 2014.

- Eric Ries, The Lean Startup, Penguin, New York, 2013.

- Described in detail in Chapter 4 of Lean Thinking, ibid.

- The Tesco and GKN examples are outlined in Daniel Jones and James Womack, Seeing the Whole Value Stream, Lean Enterprise Institute, Cambridge, 2011.

- James Womack and Daniel Jones, Lean Solutions, Simon & Schuster, New York, 2005.